Using a circular saw, is it possible to make a rabbet joint? The answer is yes, but safe and precise execution requires practice and expertise. A rabbet is an angled groove or notch that is frequently used to connect two sections of timber in construction projects like furniture making and cabinetry. Additionally, it can be used for decorative purposes. To create rabbet cuts with a circular saw, patience and precision are required. However, with the correct technique, each incision can be flawless.

This post will discuss the most efficient techniques for cutting rabbets with a circular saw.

What is a rabbet, and why is it used?

A rabbet is a form of groove or incision commonly used in construction projects involving the removal of a portion of the edge or surface of a material such as wood, metal, plastic, or stone. This simple but adaptable joint has been utilized for many years to connect two sections of material or provide a finished appearance. Rabbets serve several purposes, including providing additional support, forming a seal at junctions, reinforcing edges and corners, and enabling another piece of material to rest flush against the surface. In applications where two pieces of material must be united without the use of mechanical fasteners, such as in frame construction, door and window frames, and cabinetry, they are also frequently used.

Rabbets are created with saws, routers, chisels, or a combination of these implements. Material and application will dictate the requisite rabbet depth and dimension. Always use the correct tools and procedures when endeavoring to create a sturdy and secure rabbet joint.

If you lack conviction in your carpentry skills, there are a variety of online tutorials available to help you. With the appropriate tools and knowledge, you can construct rabbet joints that are always flawless.

Using a circular saw to create a rabbet has several advantages.

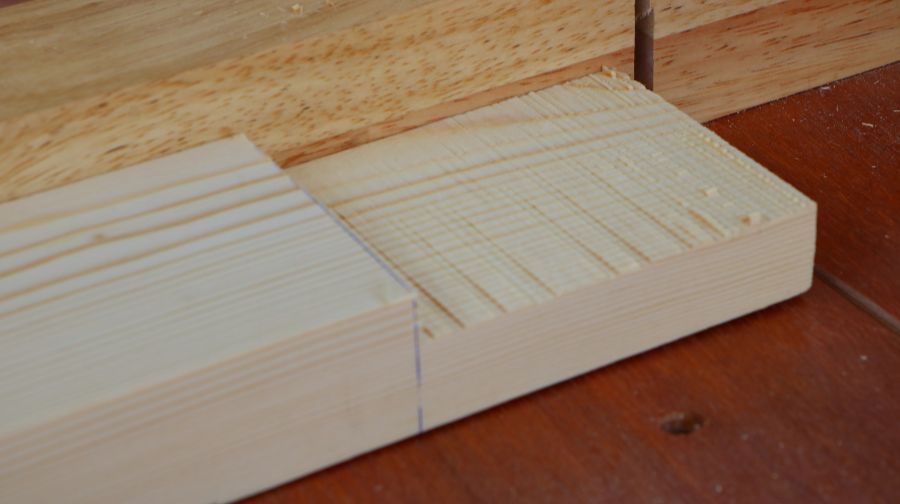

A circular saw is an excellent instrument for carving rabbets, among other woodworking tasks. Two cuts are made inside the border of a board to produce an L-shaped rabbet. This type of cut requires precision and accuracy, which are both advantages of rabbet cutting with a circular saw.

Here is a closer look at the advantages of rabbet cutting with a circular saw:

A circular saw enables precise cuts, resulting in rabbets that are precisely straight and seamless. Most models have depth-adjustable blades, allowing for precise measurements every time.

You can easily move a circular saw around the board to make incisions and make necessary adjustments. It is simple to transport to job sites and other locations where precise cutting is required due to its portability.

Unlike hand tools such as chisels or planes, circular saws enable for rapid rabbet cuts. With their powerful motors and variable speed settings, you can quickly perform intricate incisions.

A circular saw is the ideal instrument for cutting rabbets in your woodworking project because it is simple, accurate, and fast. It is one of the most versatile instruments for achieving precise results, ensuring that your finished product is of the highest quality.

How to carve a rabbet with a circular saw, step by step

Begin by fastening the wood securely to a stable, horizontal surface.

Utilizing a combination square, determine and designate the location of the rabbet cut. Use a pencil or stylus to indicate the location.

Adjust the depth of the circular saw blade to the desired depth of the rabbet cut.

Place the saw blade in front of the mark and cut slowly, allowing the saw to do the work.

Once you have completed cutting one side of the rabbet, pivot your circular saw 90 degrees and align it so that it is pointing directly across from where the first cut was made.

Start cutting the opposite side of the rabbet and halt when your mark is reached.

Verify that the rabbet is even on both sides and that there are no irregular edges or splintering wood.

Finish and sand the margins with a sanding block after cutting the rabbet to remove any rough areas or splinters.

Congratulations, you’ve completed the rabbet cut! Remember that practice makes perfect as you enjoy your new project component. You can quickly master the skill of cutting a rabbet with a circular saw with diligence.

Safety precautions when cutting rabbets with a circular saw

When using a circular saw, observe the following safety precautions:

Always use appropriate safety equipment, including safety eyewear, hearing protection, and sturdy work gloves. Additionally, it is advantageous to wear long trousers and shoes or boots with closed toes for added protection.

Never operate a circular saw without the blade protector in position to provide safety.

Before you begin cutting, examine your workspace for any nails or fasteners that the blade could snag, and remove all foreign objects.

Assure the cutting surface is stable and secure. It is simpler to cut on a flat and level surface than on an irregular one.

Reduce the risk of blowback when cutting rabbets with a circular saw using a tear fence or guide. This device assists in guiding the blade along the workpiece, thereby reducing the possibility of blowback.

Always disconnect your circular saw when not in use or when adjusting the blade to prevent accidental injury from an active blade.

Never hurry your cuts, and read the manual for your circular saw to familiarize yourself with any safety precautions associated with its use.

By adhering to these straightforward guidelines, you can successfully and safely cut rabbets with a circular saw.

Avoiding common errors when cutting rabbets with a circular saw

Setting the circular saw blade too high is one of the most frequent errors made when cutting rabbets. The rule of thumb for cutting rabbets is to position the saw blade 1/4 inch below the thickness of the material. If the blade height is set too high, the saw may cut into the workpiece on one side, resulting in an irregular cut line.

When cutting rabbets, another error to avoid is not using a straightedge as a guide. A straightedge or clamped-on fence can guarantee that the saw blade follows the desired cut path and produces an accurate, clear cut. Without a guide, a circular saw can easily veer off course and produce an inconsistent cut.

Use a saw blade with a carbide-tipped blade when cutting rabbets. Carbide is significantly more resilient than other materials, so it will not dull as quickly or readily when cutting substantial materials such as hardwoods. When cutting rabbets with your circular saw, a keen blade will also produce cleaner cuts with less tear-out, so be sure to invest in a high-quality carbide-tipped saw blade.

By following these guidelines, you can avoid common errors and achieve the finest and most accurate rabbet cuts possible when using a circular saw.