When it comes to making super-duper strong wedlock on your wooden pieces using these rabbets, there’s just one little issue – they can be as weak as tea sometimes! Ain’t that ironic? Believe me, nobody wants their hard work falling apart because of a lousy rabbet joint.

That’s why reinforcing them is so important! It’ll make sure those joints don’t go bustin’ in case your kid decides to take up trampolining indoors or something crazy like that. So without further ado, let’s dive into how to reinforce a dang ol’ rabbet joint the right way and make sure your projects hold together like peanut butter and jelly sandwiches on Wonder bread – tight and delicious!

What is a Rabbet Joint?

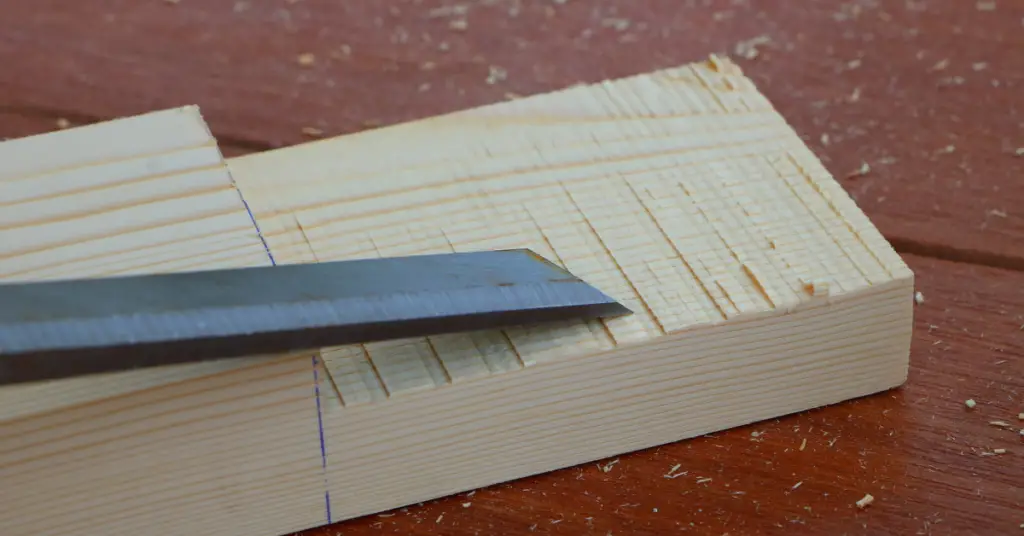

Aight, so let’s talk about rabbet joints. You know how when you wanna slap two pieces of wood together at a right angle, you gotta give each piece a lil groove to fit snugly into one another? Well, that groove is what we call a rabbet joint!

It’s kinda like when two people are good friends and they just fit together, but they still have their own unique qualities that make ’em who they are. That’s just like the rabbet joint – each piece of wood has its own thing going on, but together they create something strong and beautiful.

Now, there are different types of rabbet joints out there. You got your plain ol’ rabbet joint where one piece sits flush against the other. Then there’s the “recessed” or “rebated” rabbet where one piece fits inside the other – kinda like fitting a puzzle piece into place.

Rabbet joints come in handy for all sorts of woodworking projects – from picture frames to bookcases to cabinets. They help keep everything lined up nice and neat and add some extra strength to the structure.

But sometimes, those little grooves can get worn down over time or maybe they weren’t cut quite right in the first place. That’s when reinforcement comes in – giving those pieces a little extra support to make sure your project stays sturdy for years to come.

So now you know what a rabbet joint is! And trust me, once you start using them in your woodworking projects, you’ll wonder how you ever lived without ’em.

Why Reinforce a Rabbet Joint?

Whether you’re a novice woodworker or a seasoned pro, you’ve probably dealt with rabbet joints at some point. They’re an essential part of creating furniture and artworks that stand the test of time. But what if I told you that even a sturdy-looking rabbet joint could fail due to lack of reinforcement? That’s right, my fellow crafters, sometimes we need to give our joints extra support just like how we all need someone to lean on when things get tough.

Picture this: you’ve put in hours of hard work and sweat into your latest project, only to have it fall apart because the joint ends up disintegrating due to weak reinforcement. It’s enough to drive anyone into a fit of rage! And let’s be honest here, no one likes having wasted their precious resources on something that is unstable or unreliable.

That’s why reinforcing your rabbet joints is absolutely key. Think of it as adding an additional layer of protection against time and elements – giving the joint extra strength so that it can withstand whatever comes its way. Reinforced rabbet joints are like superheroes- they protect our creations from harm!

Let’s face it folks – we all want our creations to last forever (or at least for a while). That means taking the time and effort needed for proper reinforcement will pay off in spades later down the line.

So always remember, don’t skimp on those reinforcements my friends – make sure everything stays sturdy and secure. You wouldn’t want your beautiful bookshelf collapsing under the weight of your beloved books now would ya? So gear up and reinforce those rabbet joints with vigor!

How to Reinforce a Rabbet Joint

A’ight fellas, listen up! If you’re workin’ on a piece that’s gonna go through some serious wear and tear, you gotta make sure those rabbet joints are reinforced real good. Otherwise, your project might fall apart faster than a cheap suit.

First things first, let’s talk about glue reinforcement. Get yourself some high-quality wood glue and apply it evenly along the surface area of one piece of wood’s ‘rabbets.’ Stick ’em into place using some clamp support or nail gun, whatever floats your boat. Hold up now, we ain’t done yet – use any extra glue that leaks out to fill in any gaps between the joint pieces. You don’t want your joint falling apart like humpty dumpty just because you were too stingy with that glue now do ya?

Now if you wanna kick it up a notch, try connector reinforcement instead. What you gotta do is fit connectors called ‘biscuits’ into space created within two-level at the workstation. Then drill holes inside both pieces of timber and fitting screws in from the previous hole manually finding a good can grip.

And finally, there’s a screw-reinforcement method. This one’s pretty simple – just place screwing nuts inside the rabbet area to provide the tightness required then check for proper diameter measurements before fastening new nails through the main structure as well as rabbets inside new screws or just glue if sizing feels too small based on product decision making.

Remember folks, whichever reinforcement method you choose depends on what kinda project you’re tackling and how much time ya got. If it’s an heirloom treasure chest passed down since Ulysses S delivered his final speech then take more time with extra care when picking materials.

Tips for Successful Reinforcement

So, you’ve decided to reinforce your rabbet joint. Good for you! Here are some tips to make sure it’s a success:

Measure twice, and cut once.

This old adage has been around for ages because it works. Before you begin reinforcing, make sure you know exactly what pieces need reinforcement and how much material is necessary. Triple-check all measurements before making any cuts.

Let the glue dry thoroughly.

Patience pays off in woodworking, especially when it comes to glue. Don’t rush the drying process or else you may end up with weakened joints that can easily break apart later on down the line.

Use clamps where possible.

Clamps can be your best friend when reinforcing a rabbet joint. They help hold everything in place while the glue dries and ensure a tight fit between the two pieces of wood.

Choose reinforcements wisely.

Different materials work better for different types of rabbet joints and projects in order to achieve successful performance expectations. Avoid choosing something out of trend based on its popularity because these decisions aren’t hinged on reality-based principles but rather just fad word-of-mouth.I resist those trendy products/products tend often not to be as durable as professionals say they typically do,I suggest staying true to established materials brands

Regulations – pay attention to industry regulations

From product standards planning guidelines through pre-performance measurements, and beyond large reviews, there are various state-level laws connected to providing widely accepted methods protection regulating construction quality standards for reinforced woodwork structures, so it’s important to stay abreast of all statute codes and legal update news alerts being appropriately informed

Like my dad used to say, “An ounce of prevention is worth a pound of cure.” In other words, take preventive measures instead during remediation efforts, to secure strengthened, long-lasting Rabbet Joint outlooks.. And don’t forget: always measure twice!

FAQs

What kind of glue should I use for reinforcement?

Well, buddy, you can use different types of glue depending on the project you’re working on. Some options include yellow or white PVA glue or polyurethane glue.

Will my joints become weaker after reinforcement?

No way, man! You’ll be reinforcing those rabbet joints to ensure they stay strong and withstand any pressure thrown their way.

Can I reinforce a joint that’s already been fixed?

Aha! That depends, my friend. It may be possible to repair a settled joint using one specified fixing process with supervision from an expert or structural engineer.