A pipe clamp is a type of clamp with two clamping jaws that slide along a pipe. There are so many helpful options when it comes to clamps for your project. Each clamp has a specific purpose and function that separates it from the others. I’ve researched through the internet and put together a quick summary on pipe clamps.

What does a pipe clamp do? A pipe clamp holds your material stationary using 2 adjustable clamps that slide along a threaded metal pipe. They are commonly used in glue-up projects where you need to connect multiple boards or panels together to create a larger piece, tables, doors, boxes and cabinets.

Keep reading below to learn more about the pipe clamp and what it can be used for.

What Does A Pipe Clamp Do?

One important use of a pipe clamps is the use of pipe clamps during woodworking, this is for edge gluing. A pipe clamp is made of two basic structures— an adjustable jaw and a pipe threaded through it so that the gap between the jaws can be adjusted according to the need.

Clamps are necessarily important in carrying out home repairs and home improvement projects. There is not toolbox that is complete or fully set without clamps, and this is why the presence of clamps can not be overemphasized. Pipe Clamp basically are used for the edge gluing.

Clamps can be used to make makeshift table tops and cabinet components. Pipe clamps are also quite handy when it comes to assembling all four sides of boxes and cabinets. Pipe clamps is that which holds the boards together and gives the material some structure. Through fixing the clamps in the sides, the sides of the packaging boxes can be brought together and glued. Pipe clamps are used for corner framing.

When you are working on projects with wood, pipe clamps can be used to cut symmetrical corners. Through the use of special pipe clamps, you can always get perfect 90 degree angles when cutting corners. Pipe clamps are also used for bundling ropes and hoses. An amazing innovative utilization of pipe clamps is the use of them in bundling ropes and hoses so that they can be nearly stored. Pipe clamps can be used to stack away most utility items in a tidy manner.

Lastly, Pipe clamps also help in holding fixed pipes in place. They help in providing support to pipes that have to be suspended overhead.

What Is A Pipe Clamp?

A pipe clamp is a type of clamp that is widely different from the parallel clamp. A pipe clamp is a type of clamp usually used for woodworking, piping or they are also utilized in cabinet shops. Pipe clamps majorly comprise of commercially produced clamp heads or “jaws” and a common threaded pipe.

Moreover, the capacity of the clamp is largely decided by the length of the pipe used. Pipe clamps are basically used to connect the pipe to the pipe hanger assembly. Pipe clamps are available in diverse diameter sizes, the common sizes are the “½ or ¾”. The pipe is usually threaded on both ends. One head is fixed on the pipe by spinning it onto standard pipe threads. Moreover, it includes the screw mechanism for tightening the clamp.

This head has a mechanism that allows it a smooth clamping operation. Pipe clamps are quite similar with the bar clamps, but they are quite inexpensive and cheap to afford or purchase. There is a distinct kind of versatility that the pipe clamps possess that the bar clamps do not including some other bars.

This versatility is gotten from an amazing ability to use numerous lengths of pipe to suite one’s desires. Possessing threads at both ends of the pipe gives rooms for the usage of pipe couplings, bringing together two lengths of pipe to extend the length of the clamp.

What Are The Best Pipe Clamps?

Pipe clamps are an affordable clamp option because your just purchasing the clamping mechanisms. You will also need to purchase a galvanized, cast iron, or black steel pipe with threads to connect the clamps.

For larger projects you can just connect multiple basic size pipes together instead of purchasing one giant size pipe.

Here is a selection of the Best Pipe Clamps:

How To Prep Your Brand New Pipe Clamps.

Subscribe to Chris Parker : Woodworking – DIY – Tool Reviews on Youtube

Are Harbor Freight Pipe Clamps Any Good?

Harbor Freight makes affordable pipe clamps with a lifetime warranty that guarantees the tool to be free from defects in material and workmanship for the life of the product; some limitations do apply. They have 4.6 out of 5 stars based on 246 reviews on their website and 98% of customers would recommend their pipe clamps.

Mistakes can happen and parts can make it to market with undetected defects which a few reviews stated but with Harbor Freight’s warranty it seems like a good affordable option.

Can You Use PVC For Pipe Clamps?

You can’t use PVC as a replacement for the steel threaded pipe because the PVC won’t have a threaded edge to connect your end clamp to and the PVC pipe could bow at some point with the pressure while your piece is drying. You can use PVC as an added exterior to the steel pipe to prevent glue from dripping and drying on the pipe. You could just test the length needed for your project then measure and cut a PVC pipe to size.

There are other more simple option to prevent glue from getting on your clamp. Watch some of the clamp tip videos in this article to see them.

How Many Pipe Clamps Do I Need?

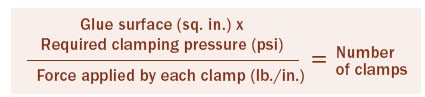

You can calculate how many pipe clamps you need for your project with this equation. Glue Surface (sq. in) X Required Clamping Pressure (psi) / Force Applied By Each Clamp (lb./in/) = Number of Clamps needed.

Are Pipe Clamps Good For Woodworking?

Yes, Pipe Clamps are good for woodworking. They are very helpful for panel type glue-ups. If your project requires connecting multiple pieces of wood to create a larger and wider piece then pipe clamps can be a good option for your woodworking.

How Do You Use Bessey Pipe Clamps?

The rear jaw slides over the end of the pipe and can be positioned anywhere along the pipe as needed. 4 spring loaded catch plates inside the rear jaw allow for quick 1 handed positioning but hold the jaw firmly when released. The front jaw with it’s threaded screw and movable face plate screws onto one end of your threaded pipe. Spin the clamp handler clockwise to tighten the clamp jaw.

You can apply a piece of painters tape over the steel pipe to prevent any glue from dripping and drying on the pipe. They can be assembled onto any length of pipe you need for the project. You can connect multiple basic sizes of pipe to make an extended size needed for larger projects.

Bessey H-style BPC pipe clamps

Subscribe to Neponset River on Youtube

What Kind Of Pipe Do You Use For Pipe Clamps?

You can use galvanized, cast iron, or black steel pipe with treads1/2 inch or ¾ inch in diameter for pipe clamps. The black steel is typically less expensive but could leave black marks on your project. You can apply a piece of painters tape over the clamp to prevent the black marks and glue from dripping and sticking to the pipe.

How Do Pipe Clamps Work?

You connect two jaw clamp pieces to a galvanized, cast iron, or black steel pipe with treads 1/2 inch or ¾ inch in diameter. The rear jaw slides over the end of the pipe and can be positioned anywhere along the pipe as needed. 4 spring loaded catch plates inside the rear jaw allow for quick 1 handed positioning but hold the jaw firmly when released.

The front jaw with it’s threaded screw and movable face plate screws onto one end of your threaded pipe. Spin the clamp handler clockwise to tighten the clamp jaw. You can apply a piece of painters tape over the steel pipe to prevent any glue from dripping and drying on the pipe.

They can be assembled onto any length of pipe you need for the project. You can connect multiple basic sizes of pipe to make an extended size needed for larger projects.

How Do You Make A Pipe Clamp?

Purchase a galvanized, cast iron, or black steel pipe with treads 1/2 inch or ¾ inch in diameter. If you need to create an extra long pipe clamp for a large project you can purchase multiple basic size pipes and connect them. Purchase a set of pipe clamps to add to the threaded pipe.

The rear jaw slides over the end of the pipe and can be positioned anywhere along the pipe as needed. Now twist on the front jaw to connect it to the thread of the pipe. This side stays stationary and the rear jaw slides to the size you need.

How To Assemble Pipe Clamps

Subscribe to Steven Larkin on Youtube

How To Make A Pipe Clamp Storage Rack

Subscribe to A Concord Carpenter / ToolBoxBuzz on Youtube