Table saw safety should be priority #1 for anyone using a table saw. Because this is the most popular power tool in woodshops becoming an expert on table saw safety is very important. Understanding table saw safety inside and out will help grow your woodworking skills and confidence.

Are Table Saws Safe? Tables saws are actually the most dangerous tool in the woodshop, but because it is also the most popular and useful tool for your shop I put together a detailed list of table saw safety tips below.

After reading the safety tips below check out another article I wrote titled “What Is The Safest Saw?”

Are Table Saws Safe?

Safety is a much a matter of attitude and common sense as correct technique. The table saw is a powerful machine; all the safety devices in the world will not make up for a cavalier attitude or sloppy work practices. On the other hand, a woodworker should not approach a table saw with trepidation; a timid operator, someone reluctant to hold a workpiece firmly while cutting it, faces as many risks as a careless worker. Caution mixed with confidence stemming from an understanding of the machine and the task at hand should be the woodworker’s guide.

Read the owner’s manual supplied with your saw. Before starting a job, make sure you know how to use the safety accessories that are designed to protect you from specific injuries while operating the machine. Use devices like push sticks and featherboards to protect your fingers from the blade.

A hold-down device is a worthwhile investment. Remember that not only your fingers and hands are at risk but a safe workshop also includes hearing protectors, safety glasses and dust mask.

Table Saw Safety Tips:

- Use a safety guard whenever possible. Before making a bevel cut, confirm that the guard will be clear of the blade.

- Do not leave the saw running when it is unattended.

- If you are interrupted, complete the operation under way before turning off the saw and looking up.

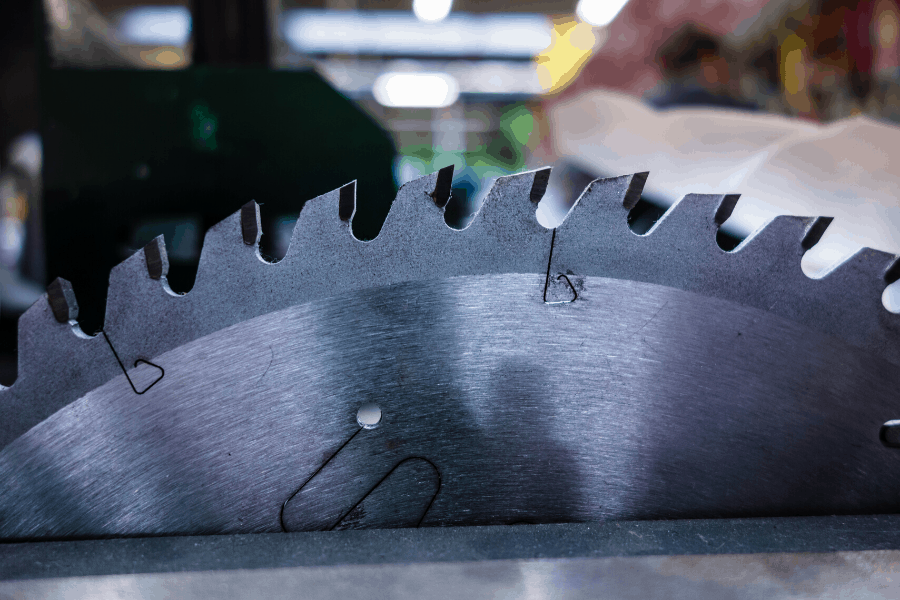

- Follow the manufacturer’s instructions to change accessories; unplug the saw first. Make sure that saw blades and cutters are sharp, clean and undamaged.

- Before cutting a workpiece, remove any loose knots from it using a hammer. Inspect salvaged wood for nails and screws before cutting.

- Do not start a cut until the blade is running at full speed.

- Before using the saw each time, inspect it’s safety features. Make sure there is no binding or misalignment of moving parts. Do not use the saw until such problems are corrected.

- Always feed wood into the saw blade against the direction of blade rotation.

- Make sure the rip fence is locked in position before ripping.

- Do not use the miter gauge in combination with the rip fence to make a cut – except when the blade does not cut completely through the workpiece, such as for a dado or a groove.

- Use the rip fence or the miter gauge for all cutting operations; never attempt to cut freehand.

- Before ripping a board, ensure that the edge in contact with the rip fence is smooth and completely straight and that the surface against the table is flat.

- Stand to one side of any workpiece during any cutting operation in case of kickback.

- If you have to reach past the blade, keep your hands at least 3 inches away from it.

- Use a wooden stick, rather than your fingers, to clear wood scraps from the saw table.

Subscribe to This Old House on Youtube

Woodworking Joke:

A woodworker called his brother-in-law, who was always borrowing his tools.

“Is it okay if I bring my table saw over and leave it in your garage?” he asked.

“Well, of course, but why?”

“Oh, it’s a little lonely. It wants to be near the rest of my tools.”