Bandsaw blades don’t last forever, but they are durable and can take on quite the workload. I wanted to learn more about how long these blades should last and how to extend the life of your blade. Here is a summary of the information I was able to dig up on bandaw blades.

How long should a bandsaw blade last? On average your bandsaw blade should last 6 months to as long as a few years depending on what your cutting with it. Make sure to match your blade strength and quality to the project and material your cutting. Once it goes dull its time to replace and if the blade gets bent it is possible to straighten but it’s safest to just replace it.

Keep reading below to discover more about how long your bandsaw blade should last.

How Long Should A Bandsaw Last?

How long a bandsaw lasts depends mainly on the materials the band saw is used to cut, the condition of the blade and the bandsaw machine itself, how the materials are fed to the saw, frequency of usage, and maintenance.

Therefore, a bandsaw can last for about six months or it can last for years, depending on the various factors that can influence the efficacy of the machine’s operation and sharpness of the blade. On top of that, not all blades are made with equal quality, so the projects it is being utilized for will be pivotal to its longevity. If you are consistently using a wood cutting bandsaw while cutting particularly hardwood, your blade will dull significantly more quickly. If you encounter a piece of metal, such as a nail in the wood you are cutting, the blade not equipped to deal with metal cutting will quickly degrade, dull, and possibly break.

What Is A Bandsaw?

A bandsaw is a fantastic tool that has a metal sharp edge with teeth that will slice through various sorts of workpieces. A band saw is utilized for metalwork, carpentry, and for most woodcutting jobs.

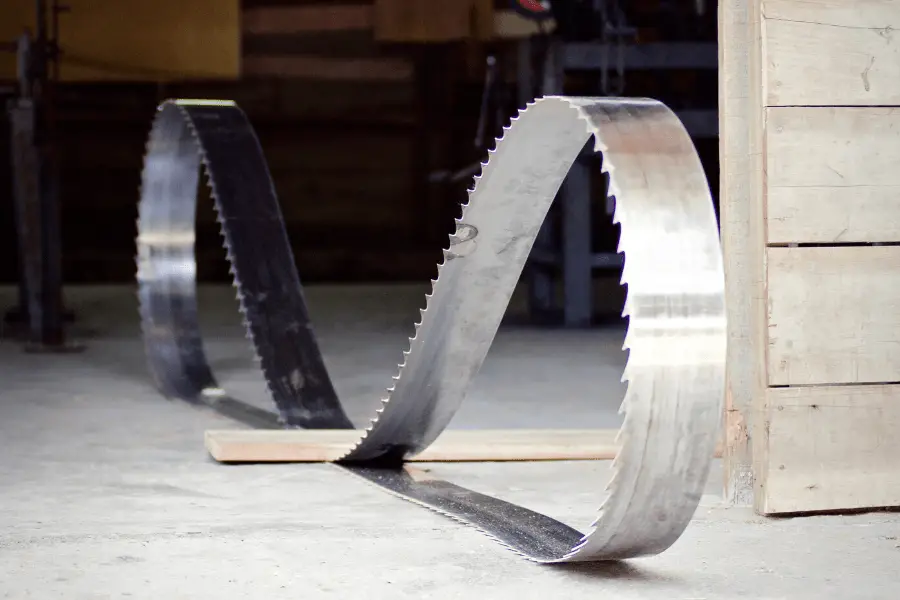

Bandsaws are most effective for lumber cutting. The majority of these saws are found at a wood factory where they utilize industrial-sized bandsaws to make the primary cut by tearing the timber, a process during which a bandsaw will be used to cut the entire tree into segments to make it feasible for transporting or handling it down for further refinement. The enormous bandsaw also lessens waste to help make the most out of every piece of available lumber. Bandsaws utilized in wood factories are commonly huge and risky to operate. Due to their intense and taxing work, they require regular and significant upkeep to perform at an optimum level.

The Bandsaw

Subscribe to Jonathan Katz-Moses on Youtube

Types Of Bandsaws

- Metal Bandsaws: These are intended to cut into and through tough metals, however, in appearance, they do not look much different than those used for wood cutting.

- Wood Bandsaws: A wood bandsaw is an apparatus commonly utilized by both expert and amateur carpenters.

What Causes A Bandsaw To Break?

There are a variety of reasons why a bandsaw might be breaking. Most commonly the bandsaw breaks because it is used incorrectly. When the blade is tasked with a job it was not meant to perform, the blade can get worn out rapidly. Similarly, certain materials should be cut at certain speeds, so cutting them too quickly can dull or crack the blade. If the blade gets heavy use; it should be regularly maintained and serviced to ensure it continues to operate optimally.

Some blades are over tensioned. While that is certainly preferable to a blade being too loose, over tensioning a blade can more quickly decrease the blade’s life by causing cracks on the back edge, blade breakage, and cause cracks to form on gullets.

The bandsaw blade can be of low quality. The cheaper ones may be more cost-effective, but they do not have the longevity that a premiere blade can get you. The cheaper blades wear out faster and reach the end of their life much more quickly by becoming dull and blunt. This is usually evident by rougher cuts, decreased cutting ability, angled cuts, and the bandsaw becoming noisier.

The fault for breakage may not always fall on the blade as sometimes there might be a machine defect at play. Any small misalignment can stress the joining weld and can put a twist in the blade as it circulates.

Here is a link to an article I wrote on how to straighten a bandsaw blade.

How To Prevent Bandsaw Breakage?

First and foremost, you must make sure that the bandsaw is being used for the appropriate purpose. Attempting to cut metal with a wood bandsaw is an invitation for problems.

Maintain a straight clean cut by the blade by always ensuring appropriate tension. As long as the blade edges aren’t slipping on the wheels when cutting, and the cut is straight then the tension should be correct. Tension might need to be increased when cutting thicker stock.

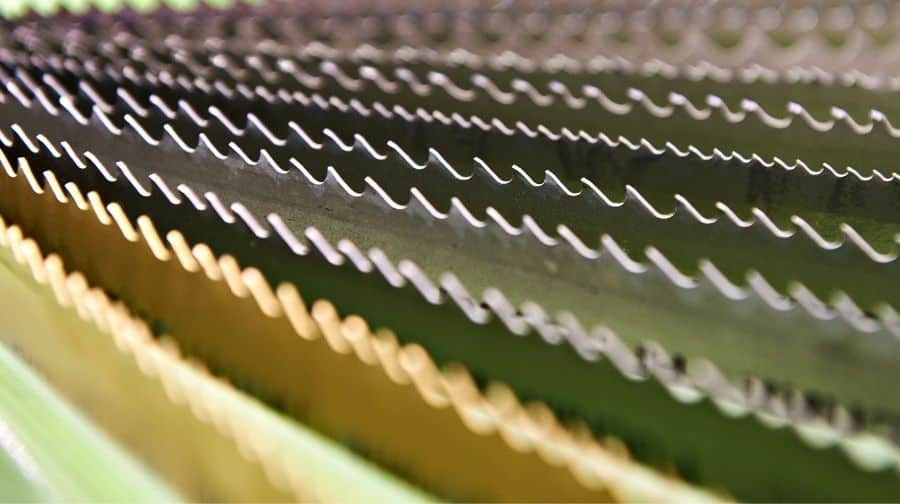

It’s also important to verify that the tooth pitch is appropriate for the cutting application: The tooth pitch of your blade sharp edges must be appropriate for the job at hand, if it isn’t, the quality of the cut can be affected, and the life duration of your blade diminished.

Most aspects of a bandsaw can be taken care of with regular maintenance checks. A new blade should be allowed to run at a 50% reduced feed for about 5 minutes to allow the blade points to wear in.

How Much Does A Bandsaw Cost?

There are numerous bandsaws out there that you can buy. This depends on the job you need to use it for. Example of bandsaws and their costs are recorded beneath:

- Makita XBP02Z 18V LXT Lithium-Ion Cordless Portable Bandsaw: This bandsaw cost around $315 and it has a cutting capacity of 4-3/4 inches. It also has a cutting speed of 275 – 530 ft/min.

- DEWALT 20V MAX Portable Bandsaw: It costs about $195 and has a cut capacity of 2-1/2 inches.

- WEN 3959 2.5-Amp 9-Inch Benchtop Bandsaw: It has a depth cut of 3-1/2 inches and will run you about $120.