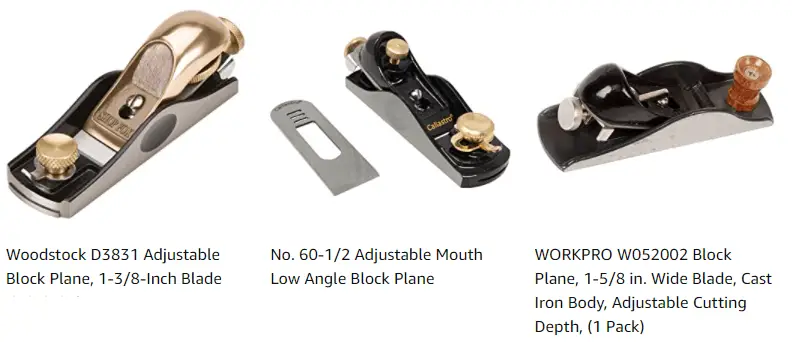

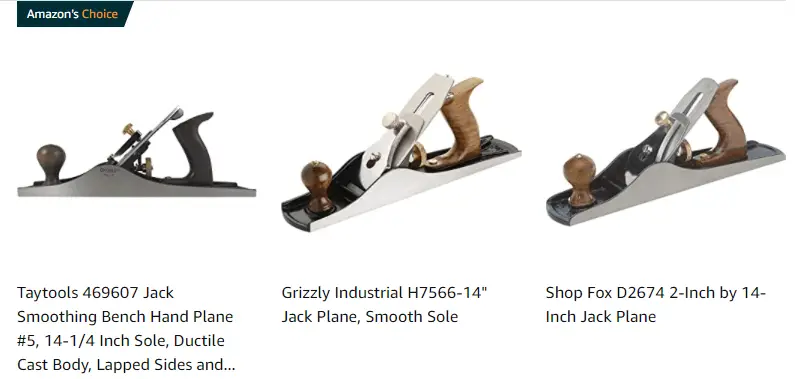

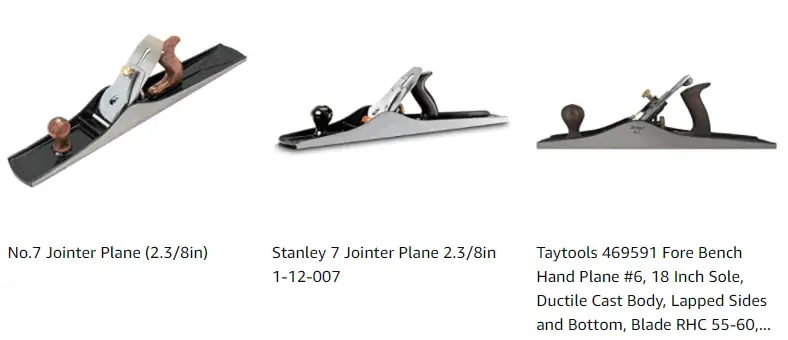

THREE COMMON HAND PLANES for workshop use are the block plane, jack plane and Jointer plane.

Block planes are very handy general purpose tools. They can be used to plane with the grain, but they have shallow blade angles and fiat soles so they can also plane end grain effectively. Their small size makes them easy to manage and convenient to store in your tool box.

Jack planes are medium-sized planes with a slight curve in the sole. Their main purpose is to reduce board thickness by surface planning (see photo above).

Jointer planes (also called try planes) have long soles that can ride a board edge smoothly. Their main use is to smooth board edges, especially in preparation for edge gluing.

Thickness planning with a hand plane:

If you don’t own a power planer and need to reduce the thickness of a board slightly, a jack plane is the tool you’ll want to use. The fastest way to remove stock is by roughing with the plane:

Scraping the plane diagonally to the direction of the grain. To remove smaller amounts of material, and to smooth out after roughing, use a smoothing blade so the blade is diagonal to the wood grain, but follow the grain direction as you push the tool across your workpiece.

Sharpening Plane Irons:

Plane blades (called irons) are sharpened in much the same way as wood chisels, typically at an angle of 25 degrees. To maintain a steady angle on the Irons, you can purchase a honing guide.

What is a block Plane Used For and How to Adjust a Block Plane

So what is a block plane really used for. there is a lot of misconceptions about it, and I hope to clear those up.

Hand Plane Selection, The Versatile # 5 1/2 Jack

Rob does a quick review of the Woodriver jack plane, a great do-all plane, long and heavy for the shooting board and manageable as a general purpose on the bench.

How to use a Wooden Jointer Plane

Bill Anderson shows how to use an 18th Century style wooden jointer hand plane to joint a board’s edge for glue-up.