If you are reading this article, the chances are good that you have plywood sitting in your garage or basement. You might not know when it was invented, but there is a good chance that when you get home tonight to start working on your latest DIY project, the first thing you’ll reach for is some plywood. Plywood has become an integral part of our everyday life, and when we take time to stop and think about all the ways it impacts us, we find out just how incredible its invention truly is.

Table of Contents

What is Plywood?

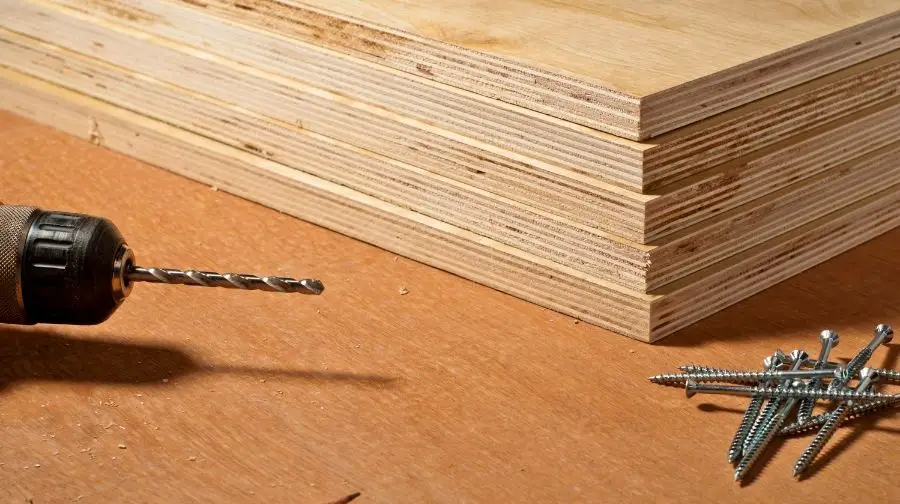

Plywood is typically made from softwoods like pine or spruce, which are easily cut into thin layers using a machine known as the ‘veneer lathe.’ The veneer lathe uses one rotating disc to hold down the face sheet of wood, while another rotates on top of it. The two are then sanded down to form perfectly even layers.

Once the veneer is complete, it’s glued together in a very specific way so that when pressure is applied during manufacturing, all of its strength components align themselves at once and give plywood its extraordinary strength. Plywood gains strength from this multi-layer design because it is able to resist twisting or bowing, which would otherwise compromise the wood’s strength.

What Are The 3 Types Of Plywood?

There are three types of plywood: interior, exterior, and marine. The construction grade plywood is the type that’s used for building cabinets and other furniture. It’s also available in higher grades that can be used for roofs, floors, and walls of homes and buildings.

- Interior Plywood

Construction grade plywood is the type that’s usually sold in home improvement stores and lumberyards. It has a variety of uses, such as building cabinets, sub-flooring, and shelving inside homes, offices, and buildings.

- Exterior Plywood

Exterior plywood contains more glue than construction-grade plywood. This makes it stronger and more water-resistant. As a result, exterior plywood is ideal for use in porches, decks, and roofing.

- Marine Plywood

Marine plywood is like exterior plywood, but special additives make it more resistant to warping, cracking, or rotting. It’s also waterproof and stronger than regular residential-grade wood.

Discover 1,000 Hours Of Step-By-Step Woodworking Videos

It’s called Woodwork101. A database of detailed videos and blueprints in crystal clear, mouth-watering HD that will take you by the hand and show you that DIY home projects done the right way are easy, fun, and always of top quality… turning a dream into reality in a heartbeat. Getting you that perfect build each and every time.

Different types of Plywood and Their Uses

Subscribe to Kody Horvey on Youtube

Properties Of Plywood

Here’s the list:

- Plywood can easily bear heavy loads without sagging.

- A sheet of plywood is more water-resistant than a solid board of the same thickness.

- Plywood is relatively inexpensive, and its low cost is one of the main reasons why it’s used for building decks and roofs on houses around the world today.

- Plywood is much easier to work with than solid wood since it can be sawed, planed, and drilled.

- Plywood can be glued or nailed as easily as a solid board of the same thickness, but the joints are stronger because plywood has numerous cross-grained layers that resist separation.

- The structure of plywood can withstand changes in temperature and humidity better than wood because it is less likely to shrink or warp than solid wood.

- Plywood is much lighter than solid wood. For example, a sheet of plywood that’s 1-inch thick weighs around 30 pounds, while a solid piece of lumber with the same dimensions weighs more than 50 pounds.

- The joints in plywood are stronger than solid wood since they provide additional support, and this makes it less likely for the plywood to crack or split.

- Plywood sandwich boards are more stable than solid platforms because the cross-grained construction of plywood absorbs vibrations better, making it less likely for the platform to vibrate or shift while people are walking on top of them.

- The smooth surface of plywood makes it easier for artists to create works of art.

Plywood Sizes

Most plywood sold today comes in either 4 feet by 8 feet sheets or 4 feet by 12 feet sheets. The standard dimensions of a sheet of plywood are 4 feet by 8 feet, although sheets with dimensions as small as 2 feet by 4 feet or as large as 8 feet by 16 feet are available.

Plywood panels have been used to cover the roofs of houses for centuries now, but there was once a time when people used individual pieces of wood to build their homes.

[Video] 3 Most Common Mistakes

When Setting Up Shop

A woodworking friend of mine shared this video by Ralph Chapman with me that helped him set up his workshop.

The video explains the benefits of Ralph Chapman’s guide about setting up an affordable workshop and avoiding the most common mistakes offers to anyone interested in woodworking.

When Was Plywood Invented?

Plywood was first invented in the early 1800s. It was first patented December 26, 1865 by two British men by the names of Edward Drummond Libbey and William Everett. But, it wasn’t until 1907 when German inventor Wilhelm Baumann invented a special lathe designed to accommodate these plys so they would glue together properly. This machine was known as the veneer lathe.

The original wood-based panel product known as plywood was invented in Britain in the mid-1800s. However, by World War II, plywood had become a little-used construction material of a relatively low quality that was only manufactured domestically in small quantities for specialized applications requiring its specific properties.

It was not until the post-war period (the 1950s and 1960s) that plywood enjoyed a resurgence as a versatile construction material commonly used in large-scale residential and commercial buildings.

When Was Plywood First Used In Construction?

The first time plywood was used in construction began with a company by the name of Steiner Brothers, who produced flooring using industrial soaked kraft papers soaked in glue and pressed together to produce panels that were then laid down on the factory’s sub-floor.

These panels were extremely flimsy, but they worked well enough to protect the sub-floor from damage. When Steiner Brothers installed plywood floors in the East Texas pine forest for Louisiana governor Huey Long’s mansion, it was so different that he wasn’t sure if he liked it or not at first because of its sponginess beneath his feet.

In 1932, a German company called Weyerhaeuser started using plywood to make the staves of a barrel. Up until this point, they were made from solid pieces of wood with a single grain direction and soldered together at their ends.

5 Mistakes Buying Plywood – Don’t Waste Your Money!

Subscribe to Fix This Build That on Youtube

When Was Plywood Widely Used?

During World War II, plywood was widely used to replace steel in the construction of fighter planes. After the war, it was widely adopted by boat manufacturers who appreciated its ability to be easily molded into different shapes for improved speed and performance.

After the war ended, building codes began requiring all homes to have installed plywood sheathing on their roofs. This was meant to help prevent fires because plywood is naturally resistant to fire. A few years later, it made its first appearance on church roof designs.

There wasn’t much of an emphasis on using plywood for building furniture at the time since wood was still expensive due to limitations on shipping supplies following the war, and plywood was not well-known. However, the first piece of furniture made from plywood was a laundry chute for a department store in New York, which was built using three layers of wood and beeswax.

Even though the plywood weighed four times as much as solid wood, it still worked well enough to be installed on the store’s rooftop so employees could toss their clothes into a chute and watch the laundry slide down to the main floor.

When Was OSB Invented?

In 1960, a company called Weyerhaeuser invented what is now known as oriented strand board (OSB). It was made from wood strands that were broken up by heat and steam before they were bonded together with resin using a special foaming machine. This new method of construction was considered a major improvement in the production of plywood because it produced a more uniform product with improved strength and appearance.

What Did They Use Before Plywood?

Before plywood people used wood in its natural form for building purposes. But when solid pieces of wood began to run out, builders had to find a way of preserving existing trees so they wouldn’t be cut down.

Plywood was the first product of its kind on the market, meaning there was nothing else similar for people to compare it with. It wasn’t until around two decades later that the idea of making sheets of wood joined together by glue caught on. The new product was called ‘particleboard,’ and it didn’t replace plywood because while particleboards were cheaper to produce, they weren’t as strong or attractive as plywood.

How Plywood Is Made In Factories? (Mega Factories Video)

Subscribe to Engineering World on Youtube

How Was MDF Invented?

Milled fiberboard (MDF) was invented in 1937 by John Borden, who combined sawdust with resin to produce a material that was much lighter than particle board but just as strong. MDF is considered to be superior to particleboard because it has more surface area for gluing, which increases the strength of the finished product while reducing the amount of resin needed.

Every year, millions of tons of plywood are used in residential construction. It is the most common type of sheathing that is installed on roofs, floors, and walls. Plywood has also been used for centuries in boat building, making MDF a more modern invention.