Red oak is a beautiful wood that can have stains in a variety of colors. It suits furniture and flooring. If you are considering using red oak in your next project, you may wonder if you should use polyurethane on it.

In this blog post, we will discuss the pros and cons of using polyurethane on red oak and help you decide if it is the right choice for your project.

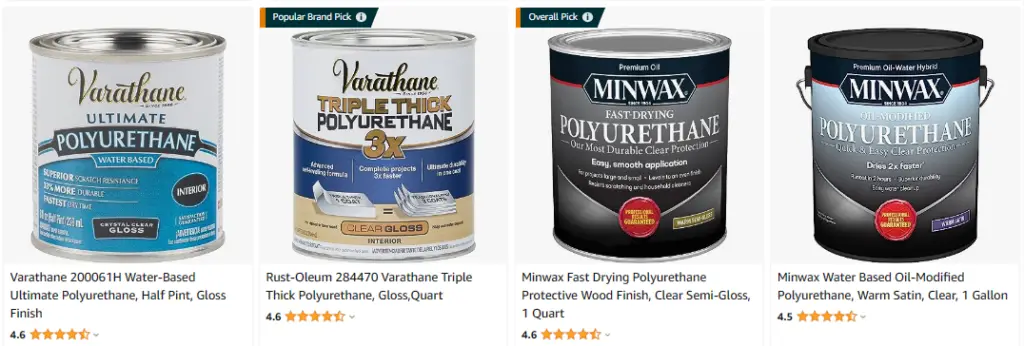

Click Here To Check The Pricing On Amazon

Should I Use Polyurethane On Red Oak?

Yes, you should use Polyurethane on red oak; it protects it from scratches and everyday wear and tear. It is important to note, however, that polyurethane works only on clean and dust-free surfaces. In addition, you will need to apply a base coat of primer before applying the polyurethane topcoat.

When it comes to choosing polyurethane, there are two main types: oil-based and water-based. Oil-based polyurethanes take longer to dry but provide a more durable finish. Water-based polyurethanes dry faster and have less of an odor. But they may not become as durable as oil-based polyurethanes.

No matter which type of polyurethane you choose, apply it in thin coats and allow each coat to dry completely before applying the next. You should also sand between each coat for a smooth finish. Lastly, don’t forget to clean up any drips or excess polyurethane before it dries. Otherwise, you’ll have a big mess on your hands!

What Is Polyurethane And What Are Its Benefits?

Polyurethane is a finish that is applied to wood to protect them from scratches, scuffs, and other everyday wear and tear. Polyurethane comes in both oil-based and water-based formulas. Oil-based polyurethanes have a higher VOC (volatile organic compounds) content than water-based polyurethanes, which means they’re more toxic and have a stronger odor. Water-based polyurethanes are more durable and offer better protection against scratches and scuffs, but they can raise the grain of the wood, so it’s important to sand the wood before applying the finish.

Polyurethane is available in different sheens, from high gloss to satin to matte. High-gloss polyurethane is very durable and easy to clean, but it can be too shiny for some people’s taste. Satin and matte finishes are less durable than high-gloss, but they’re more forgiving of scratches and scuffs.

Polyurethane is a great way to protect your wood floors, furniture, and other wood products from wear and tear. It’s available in different formulas to suit your needs, and it comes in a variety of sheens to match your style.

Subscribe to Angela Marie Made on YouTube

What Are The Pros And Cons Of Using Polyurethane On Red Oak?

Polyurethane is one of the most popular finishes for wood floors, thanks to its durability and easy maintenance. But like all finishes, it has its pros and cons. Here’s a look at some of the key considerations when deciding whether or not to use polyurethane on red oak:

PROS

- Polyurethane is extremely durable, making it ideal for high-traffic areas

- It’s easy to clean and maintain

- Polyurethane can be applied in multiple coats for extra protection

- It enhances the natural beauty of the wood

CONS

- Polyurethane can yellow over time, especially when exposed to sunlight

- It’s a synthetic finish, so it’s not as “natural” as some other options

- Polyurethane can be difficult to remove if you ever want to change the finish

So, what’s the bottom line? If you’re looking for a durable and easy-to-maintain finish for your red oak floors, polyurethane is a great option. Just keep in mind that it’s not the most natural finish available, and it can yellow over time.

How Do I Decide If Polyurethane Is The Right Choice For My Red Oak Project?

You sanded your floors (or maybe professionally), and you’re ready to protect them with a new finish. You’ve heard about the benefits of polyurethane. But you’re not sure if it’s the right choice for your red oak project.

Here are a few things to consider when making your decision:

- The type of wood you’re working with. Polyurethane works best on hardwoods, like oak and maple. Softer woods, like pine, can become more difficult to work with.

- The look you’re going for. Polyurethane gives a natural and matte finish. If you’re looking for a more glossy appearance, you might want to consider another option.

- The level of protection you need. Polyurethane is very durable and can withstand a lot of wear and tear. If your floors are subject to high traffic or pets, this might become the right choice for you.

Weighing these factors will help you decide if polyurethane is the best option for your red oak floors.

How Do I Apply Polyurethane To Red Oak

Applying polyurethane to red oak floors is not difficult. But it does require some care and attention to detail.

Here are some tips on how to apply polyurethane to red oak floors:

- Start by sanding the floor with fine-grit sandpaper. This will create a smooth surface for the polyurethane to adhere to.

- Next, clean the floor with a tack cloth or vacuum it to remove all the dust.

- Now you’re ready to apply the polyurethane. Use a brush or roller designed for applying polyurethane.

- Start in the corner of the room and work your way out.

- Apply an even coat of polyurethane and don’t miss any spots.

- Allow the polyurethane to dry completely before walking on it or putting furniture back in the room.

By following these tips, you can ensure that your floors will look great for years to come!

Subscribe to Falcon Flooring on YouTube

Does Red Oak Need To Be Sealed?

Yes, you should seal Red Oak wood.

Here’s what you need to know about sealing red oak:

- Sealing red oak is important because it helps protect the wood from water damage, which can lead to cracking and splitting.

- It also helps prevent the growth of mold and mildew, which can cause the wood to rot.

- The best time to seal red oak is in the spring or summer when the weather is warm and dry.

- You can use a variety of different products to seal red oak, including water-based sealers, oil-based sealers, and even waxes.

- Be sure to follow the manufacturer’s instructions carefully when applying any type of sealer to red oak.

If you live in an area with high humidity, you may want to seal your red oak regardless of where you’re using it. This will help to prevent the wood from warping or cracking.

Should Red Oak Be Sealed Before Staining?

Yes. Red oak is a very porous wood. It will absorb any stain or sealer you apply more readily than other types of wood. This can lead to an uneven finish and potential staining issues down the road. By sealing red oak before staining, you’ll ensure a more even and consistent finish.

Sealing red oak before staining is especially important if you’re planning on using a dark stain. Dark stains can highlight any imperfections in the wood. So it’s important to have a smooth and even surface to work with. Sealing the wood will help to create that smooth surface.

Of course, you don’t want to over-seal the wood either. This can lead to issues with the stain not penetrating the wood properly.

Does Red Oak Take Stain Well?

Yes, red oak does take stain well if you use a pre-stain wood conditioner. You can use any type of wood stain on red oak. But you may need to experiment a little to find the perfect color. The key is to test the stain on a small area of the wood before you commit to staining the entire piece.

There are a few things to keep in mind when staining red oak. First, the grain of the wood can become quite pronounced. This means that the stain may not go on evenly. Second, red oak is a porous wood. So it will absorb more stain than other types of wood. This can make it difficult to achieve a consistent color.

With a little patience and experimentation, you should find the perfect stain color for your red oak project.

How Do You Make Red Oak Last Outside?

You can make your red oak furniture last outside by following a few simple steps.

- First, avoid placing red oak furniture in direct sunlight. The sun can cause the wood to fade and discolor over time.

- Second, if you do need to place red oak furniture in the sun, make sure to protect it with a sealant or varnish. This will help keep the sun from damaging the wood.

- Third, avoid placing red oak furniture near heat sources. The heat can cause the wood to warp and crack over time.

- Fourth, if you do need to place red oak furniture near a heat source, make sure to protect it with a fireproof mat or blanket. This will help keep the heat from damaging the wood.

- Fifth, avoid placing red oak furniture in damp or humid areas. The moisture can cause the wood to rot and mildew over time.

- Sixth, if you do need to place red oak furniture in a damp or humid area, make sure to protect it with a waterproof sealant. This will help keep the moisture from damaging the wood.

By following these simple steps, you can help make your red oak furniture last for many years to come.