Concrete blocks are widely used for construction purposes because of their reasonable prices and many benefits in making the building firm and strong. That’s why it’s been excessively used in the USA. According to a report, it’s predicted that the revenue of concrete bricks, blocks, and pipes manufacturing in the U.S. will amount to 6 billion appx U.S. dollars by 2024.

Furthermore, when it comes to their use in construction, we may need to cut them down often as we have to shape the structure. In some cases, we need to break them into smaller parts as per the construction requirements. So, there are several methods to cut concrete blocks, and the one we’ll discuss here is using a circular saw. It’s not as difficult as it sounds, but after going through our compiled steps, it won’t sound challenging either.

How to Cut Concrete Blocks with a Circular Saw?

You can cut the concrete blocks using different tools, but a circular saw makes the cut accurate, clean, and precise while keeping you at ease and safe. Also, you can make the desired shape by moving the circular saw accordingly while cutting the concrete block. Let’s find out how it’s done and how simple it is to cut concrete blocks using a circular saw.

Step #1: Mark the Target Area

To achieve extra precision and accuracy, it’s important to mark the block first using chalk. It’s better to use a straightedge or tape to mark the line straight and measure as well. Marking helps achieve accurate results and easily follow the line when holding the circular saw and running over the block. Otherwise, you may end up ruining the block by not cutting the way you need.

Step #2: Adjust the Blades

Since measurements vary from blade to blade, we might not tell the exact measurements. However, we can surely tell that it is set according to the block’s thickness. Adjust the blades accordingly and also keep them firm and straight to the line marked by the chalk on the block. We also suggest keeping the circular saw still and wait till it reaches its maximum rotation. Otherwise, starting with a slow speed might not make the firm cut on the block.

Step #3: Place the Blade on Concrete

Hold the circular saw firmly with both hands and place it on the block where the line is marked. Now you can turn on the saw. Make sure you keep holding the saw tightly as it will definitely exert pressure on your hands or fall back if held loose.

Step #4: Make the First Cut

Never go for cutting the entire block on a single strike but rather make the one cut first. In this step, you’ll follow the drawn line and keep making the first cut all over the block. It’ll give you a clear cut line to follow it further for tearing the block apart. Also, dip the saw in the water to prevent dust that can never be good for your health. In addition, the water can keep the blade cool even when its rotation is extremely high.

Step #5: Finish Cutting

Now while completing your cut by cutting the block steady and firmly. Never apply too much pressure on the saw, but rather let the saw cut the block itself. Forcing the saw won’t work and may ruin the entire block. Once you’ve struck most parts of the block, do not keep cutting until it gets into parts. You should leave it after doing the damage while following the marked line.

In this part, let a hammer and chisel do the job by putting the chisel in the cut part and strike the hammer nicely. Striking a hammer with too much force may not break the block even. Take necessary precautions while following this step as it involves striking the block, which may break into pieces and fall back.

How to Cut a Concrete Block with a Circular Saw Video

Subscribe to CryptoSlo on Youtube

Bonus Tips

Tip #1: Wear Safety Gear

Since the process is dangerous it requires a lot of safety, you should wear all your safety gear. First, make sure you’ve worn work boots to protect your feet against falling concrete blocks on the toe area. Then, close your ears with buds as there will be noise due to the cutting block with a circular saw. Also, dust from cutting the block might enter your nose and throat, which may end up causing infections inside your body. So, cover most parts of your exposed body for added safety.

Tip #2: Hold Close Intervals During Cutting Process

Give your circular saw blades some rest while cutting the concrete block. Instead of continuously cutting the block, cut with the rest of almost 45 seconds to keep the blades cool and prevent overheating. Also, it will avoid causing damage to the blade due to putting too much pressure on it. So, it can increase the durability of blades and circular saw as well by pushing less during the process.

Tip #3: Look for A Helping Hand to Increase the Amount of Water

When cutting the concrete block, you might face a lot of dust. It can be avoided by dipping the blade in the water first. The water can also avoid heating up the blade and the entire circular saw. Another good option is that you can look for a helping hand to continuously or at some intervals pour water on the block and the saw. This will avoid both heating up and dust.

Can I Cut A Cement Block with a Circular Saw?

Yes, it might sound challenging, but when following these five easy steps, you can easily cut the concrete block with a circular saw. You don’t need to be an expert for this process. However, you need to firmly hold the circular saw, or you may end up causing yourself injury or ruining the block. Also, you must precisely follow the drawn line with chalk while cutting the block with a circular saw. If you can follow these precautions, it’s a lot easier than you expect.

Are Concrete Blocks Easy to Cut?

Yes, using the best circular saw, all safety gears, and precisely following the measurements, you can easily cut the concrete block. Even if you do not fully cut it and leave the half-cut part, you can further cut the block using a wrench and a hammer. We can conclude that you can easily cut the concrete blocks using a circular saw or any other tool you find suitable.

How to Cut Bricks and Cinderblocks in Half Video

Subscribe to Colin Chilibeck on Youtube

What is the Best Blade for Cutting Concrete?

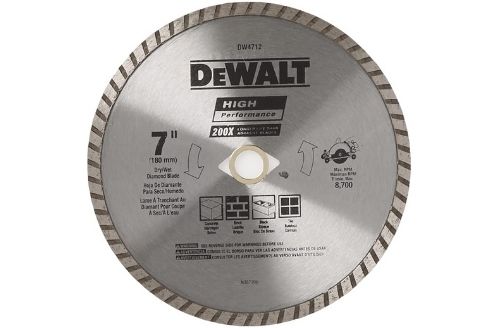

DEWALT Diamond Blade for Masonry is the best blade for cutting concrete blocks because of its sturdy construction and speed that makes the cutting process quite easy. The blade is strong yet lightweight, making it easy to use and provides 200 times more performance when compared with other typical circular saw blades. Its thinner kerf increases the speed while minimizing the dust.

Pros

- Lightweight

- Easy to Use

- Thinner Kerf

- Increased Speed

- High Performance

- Fast Cutting

Cons

- Relatively Expensive

Will A Carbide Blade Cut Concrete?

Carbide blades are often used by woodworkers and craftsmen to cut various materials. Generally, these are used for cutting wood but can also be used to cut concrete. Since the carbide blades are entirely made of carbon steel and have hardened teeth, they can easily cut the concrete block like other circular saw blades.

Cutting Concrete with a Circular Saw Video

Subscribe to Cool Stuff Guys Like on Youtube