In the woodworking world, there are a few different materials that are popular for use in furniture and other structures. One of these is MDF or medium-density fiberboard. This material is from wood fibers that have been compressed and bonded together with resin. It is a popular choice because it is strong and stable, and can also mold into many shapes.

In this blog post, we will discuss the pros and cons of using polyurethane on MDF.

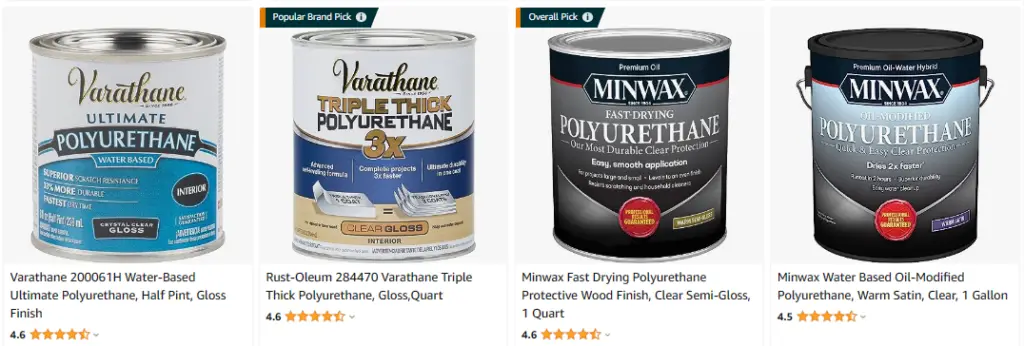

Click Here To Check The Pricing On Amazon

What Is MDF And Why Is It Popular Among Woodworkers?

MDF, or medium-density fiberboard, is material from wood fibers glued together with resin. It’s denser and smoother than particle board, making it a popular choice for cabinetry, shelving, and other woodworking projects.

MDF is also less expensive than solid wood, which makes it a good option for budget-conscious woodworkers. If you’re considering using MDF for your next project, here’s what you need to know about this versatile material.

The wood fibers are from softwoods like pine or spruce, which makes MDF a good choice for projects that require a smooth finish. There is uniformity in the fiber size, which gives MDF a consistent look when it’s sanded and painted. MDF is available in a variety of thicknesses, so you can choose the right option for your project.

What Are The Pros Of Using Polyurethane On MDF?

MDF is a versatile material that is for a variety of projects, from furniture to flooring. Polyurethane is a type of finish that can apply to MDF to protect it from scratches, stains, and water damage.

Here are some of the pros of using polyurethane on MDF:

– Polyurethane creates a durable and hard surface on MDF.

– It is resistant to scratches, stains, and water damage.

– Polyurethane can enhance the appearance of MDF by giving it a glossy finish.

– It is easy to apply and does not require any sanding between coats.

– Polyurethane has a variety of finishes, from glossy to matte.

Discover 1,000 Hours Of Step-By-Step Woodworking Videos

It’s called Woodwork101. A database of detailed videos and blueprints in crystal clear, mouth-watering HD that will take you by the hand and show you that DIY home projects done the right way are easy, fun, and always of top quality… turning a dream into reality in a heartbeat. Getting you that perfect build each and every time.

What Are The Cons Of Using Polyurethane On MDF?

MDF, or medium-density fiberboard, is a type of engineered wood that is from heat-pressed wood fibers. However, MDF can become difficult to work with because it tends to chip and splinter easily. That’s why many people choose to use polyurethane as a protective coating.

Subscribe to Everything House on YouTube

But what are the cons of using this type of sealant?

For starters, it can become hard to apply evenly. If it’s not applied correctly, it can end up damaging the MDF. It’s also important to note that polyurethane is a petroleum-based product. So it’s not as environmentally friendly as some other options.

Is Polyurethane The Best Material For Sealing MDF?

To seal MDF so it’s water resistant, you need to use a product that will penetrate the wood and form a barrier. Polyurethane is one of the best materials for this purpose. It’s available in both water-based and oil-based formulas. So you can select the one that suits your needs the most.

Water-based polyurethane has less odor and cleans up more easily than oil-based polyurethane. It also dries more quickly! But it doesn’t penetrate the wood as well, so you may need to apply more coats.

Oil-based polyurethane takes longer to dry and has a strong odor. But it penetrates the wood better and forms a tougher and more durable finish.

How To Seal MDF With Polyurethane

If you’re working with MDF, you know that it’s important to seal the material before painting or staining it. Sealing MDF helps to prevent moisture damage and makes the surface more durable. Polyurethane is a fabulous option for sealing MDF because it provides a durable and protective finish.

Here’s how to seal MDF with polyurethane:

Start by sanding the MDF surface. Use fine-grit sandpaper and sand the surface in the direction of the wood grain. After sanding, wipe away any dust with a clean cloth.

Next, apply a thin layer of polyurethane to the MDF surface with a brush. Work in the direction of the wood grain and make sure to get into all the nooks and crannies. Allow the first layer of polyurethane to dry completely before applying a second coat.

After putting two coats of polyurethane, your MDF surface will become well-sealed and protected.

[Video] 3 Most Common Mistakes

When Setting Up Shop

A woodworking friend of mine shared this video by Ralph Chapman with me that helped him set up his workshop.

The video explains the benefits of Ralph Chapman’s guide about setting up an affordable workshop and avoiding the most common mistakes offers to anyone interested in woodworking.

Can You Waterproof MDF With Polyurethane?

Yes, polyurethane is an excellent waterproofing agent, and it works well on MDF.

Apply a generous coat to the surface of the MDF, and let it dry. Your MDF is now resistant to water damage and will last much longer.

What Do You Seal MDF With?

MDF is a versatile product for a variety of applications, from cabinets to shelving. But what do you seal MDF with?

There are a few different options available, but the best one depends on the project you’re working on. If you’re painting MDF, then using an oil-based primer is a good option. This will help to seal the MDF and prevent the paint from peeling.

If you’re staining MDF, then using a water-based sealer is a better choice. This will help to protect the MDF from water damage and prevent the stain from bleeding through.

No matter what you’re using MDF for, it’s important to seal it properly. This will help to extend the life of the MDF and ensure that your project looks its best.

Can You Use Polycrylic On MDF?

If you’re looking for a durable and long-lasting finish for your MDF project, polycrylic is a superb option. This type of finish can withstand heavy use and wear, making it ideal for high-traffic areas or pieces that will see a lot of use. Polycrylic also resists staining and fading, so your project will look awesome for years to come!

Applying polycrylic to MDF is a simple process. But there are a few things you’ll need to keep in mind to ensure a successful finish. First, sand your MDF piece smoothly before applying any polycrylic. This will help the finish adhere better and create a more even appearance. Next, make sure to apply a thin layer of polycrylic and allow it to dry completely before adding additional coats. Finally, don’t forget to sand between each coat for the best results!

Subscribe to Brad Angove on YouTube

How Do I Get A High Gloss Finish On MDF?

If you want to achieve a high gloss finish on MDF, there are a few things you need to do.

First, sand the surface of the MDF with fine-grit sandpaper until it is smooth.

Next, apply a primer to the MDF and let it dry completely.

Finally, paint the MDF with a high-gloss type. Let the paint dry up in full before putting on a topcoat.

[Guide] How To Launch Your Woodworking Business For Under $1000

Click Here To View

If you’re considering turning your woodworking hobby into a part-time business check out this helpful guide on how to get started.

Do I Need To Prime MDF Before Painting?

Yes, you should always prime MDF before painting.

There are a few reasons why priming MDF is so important.

First, MDF is a very porous material. This means that paint can easily soak into the surface of the MDF, causing the paint to look uneven. By priming the MDF first, you create a barrier between the paint and the MDF, which helps to prevent this from happening.

Second, priming also helps to seal the MDF, which is important because MDF can swell and warp if it gets too wet. By sealing the MDF with primer, you help to prevent this from happening.

Finally, priming also helps to create a smooth surface for painting. This is because primer fills in any pores or imperfections in the MDF, creating a smooth surface for the paint to adhere to.

What Happens To MDF When It Gets Wet?

One downside of MDF is that it does not do well when it gets wet. The moisture can cause the material to swell and warp, making it unusable for your project. If you do get MDF wet, you’ll need to take some steps to dry it out and repair the damage.

First, you’ll need to remove any wet MDF from the area where it is put. Afterward, you’ll need to place the MDF in a dry area. You can use a fan to make the drying process faster! Once the MDF is dry, you can sand down any rough edges and then paint or finish it as desired.

If your MDF has damage from water, it is important to take action quickly to repair it. By taking action on it, you can minimize the amount of damage and hopefully save your MDF project.