Veneer plywood is an affordable and environmentally friendly way to make your building envelope more durable. Often veneer plywood is used as exterior sheathing, but it can also be used for interior walls or ceilings. Veneer plywood can be applied either horizontally or vertically, depending on the project. If you’re not sure where veneer plywood should be installed in your home, keep reading!

What Is Veneer Plywood?

Veneer plywood is a thin sheet of wood that has been glued to another exterior surface. It can consist of multiple sheets, called ply or plies, which are laid with the grain alternating at right angles for strength and stability. The two most common types are ¾-inch veneer plywood used for cabinets and ¼-inch veneer plywood used for furniture.

Veneered Plywood Sheets

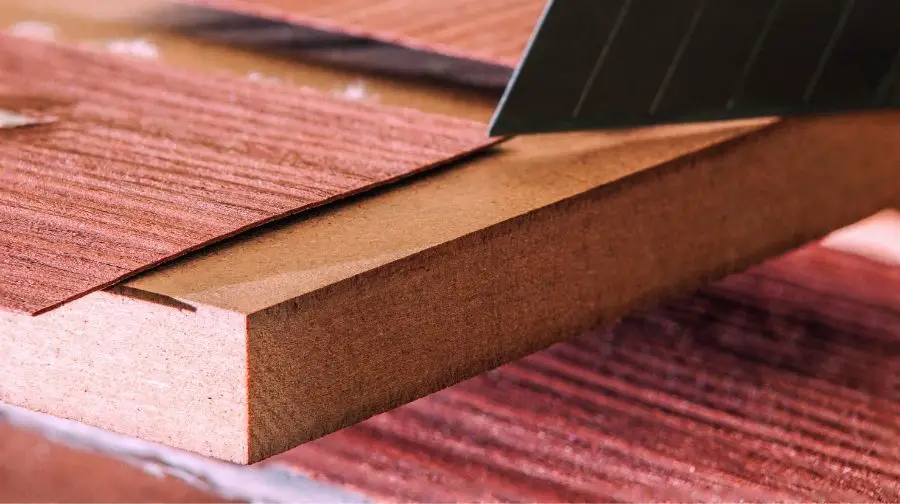

A veneer plywood sheet is a thin piece of wood that is used to cover another piece of wood. Veneer plywood sheets are usually made from a hardwood, such as maple or oak. It is glued to the substrate with a special adhesive.

Veneer plywood sheets can be used for a variety of applications, such as paneling, floors, and doors. They are available in a variety of thicknesses and sizes. They can be purchased at most home improvement stores.

Veneer plywood sheets have many advantages over solid wood boards. They are lighter in weight and easier to work with. They are also more stable than solid wood boards and do not warp or cup like solid wood boards. They also less expensive than solid wood boards.

Veneer plywood sheets have some disadvantages as well. Veneer plywood sheets can be difficult to repair if they become damaged. They are also more susceptible to moisture damage than solid wood boards.

There are several different types of sheet goods available on the market, including ¾-inch veneer plywood sheets and ½-inch thick engineered wood panels. These products provide a quick way to build storage cabinets for desks without using solid-wood material.

Veneer Plywood for Cabinets

If you are looking for the strongest cabinet construction, then use solid-core plywood. The solid core has no voids or pockets and is guaranteed to be free of knots—a common defect in veneered sheet goods that can affect strength. Veneer core plywoods have a thin sheet of wood veneer applied to thicker core material.

Veneer Plywood Panels

Cutting panels from large sheets can be challenging and is the most common reason why people choose engineered or solid-core plywood over veneered products. Cutting with an accurate straightedge, circular saw with fine tooth blades, router, and straight bit is the best method for cutting panels from large sheets.

Veneer Plywood For Cabinets

¾-inch veneered plywood has more shear strength than ¼-inch and is recommended over it when there are any concerns with deflection or sag of an assembly such as cabinets, countertops, furniture (tables, chairs), and cabinets.

How to make a Veneer Press To make Plywood to Make a Clock

Subscribe to Wood By Wright How 2 on Youtube

Veneer Plywood Grades

There are three grades of veneered plywoods: standard grade (S-GR), better grade (B-GR), and best grade (A-GR). The grading system is based on the number of plies in the sheet and its thickness, stability, and strength.

- Standard grade (S-GR)

This grade is typically used in cabinets and furniture. It has a minimum veneer thickness of 0.038 inches, stretched core, and unwarped.

- Better grade (B-GR)

This grade is often used for countertops since it provides the appearance of solid wood without its disadvantages, such as high cost, weight, or maintenance issues. It has a minimum veneer thickness of 0.04 inches, stretched core, and is warp-free.

- Finest grade (A-GR)

This is the highest quality veneer plywood available in today’s market, with a minimum veneer thickness of 0.05 inches and no stretch core or warping issues to worry about while working on your project.

Veneer Plywood Pricing

The cost of veneered plywood can vary based on the manufacturer, quality, and grade of material used in its construction, as well as the size and cut sheet availability at your local building supply store.

Finished Veneer Plywood

If you are looking for a natural wood finish with a smooth, sanded-like appearance for your projects, then it is best to choose ¼-inch veneer plywood.

Types Of Veneer Plywood

There are three different types of veneer plywoods: rotary-cut veneers (used mainly in decorative applications), sliced cut veneers, and flitch cut veneer panels.

Rotary Cut Veneer: Rotary cut veneers are made from logs with bark left on. The offcuts or trimmings that result from peeling and shaping this type of plywood can be used as decorative elements in various applications like end tables and wall paneling.

Sliced Cut Veneer: This style of veneering is similar to rotary cut veneer, but the log is debarked and sliced into thin sheets. These veneers are more expensive because they have a smoother surface than rotary-cut or flitch panels, making them ideal for fine furniture work.

Flitch Cut Veneer: The most economical of all three types of plywood, flitch panels are made by splitting a log lengthwise. They have three or four good-quality veneers on one side, which you can use for decorative purposes, and the other side with two to three lower quality layers that will be used as underlayment in low-grade woodworking projects.

Walnut Veneer Plywood

Natural walnut color appearance enables you to get a perfect match for stained woodwork or furniture projects such as cabinets, doors, windowsills, and trim. It has an uneven grain pattern that adds character and beauty to your project.

¼ Veneer Plywood

A ¼-inch veneered plywood is perfect for fine woodworking projects or where a smooth, sanded surface with natural wood appearance is desired. It has an uneven grain pattern that adds character and beauty to your project while providing superior strength to solid hardwood.

What Is Plywood-Veneer Used For?

Plywood is a strong and versatile material that has been used for centuries. It can be made from a combination of different laminates, such as wood veneer or paper fiber, with an adhesive binder between each ply. Plywood brings multiple benefits to your project, including its reduced cost compared to solid lumber, durability, stability, and strength.

Veneer plywood is a specific type of construction grade lumber that is made up entirely of laminated wood veneers or thin slices of wood with the grain running in alternating directions to make it stronger. While regular plywood sheets are at least ½ inch thick, veneer plywoods often come as thin as paper and can be as thin as a credit card.

Veneer plywood is used for a wide range of applications from furniture to cabinets, architectural elements such as staircases or flooring panels, aircraft interiors, boats, and more. It’s often chosen for its high strength-to-weight ratio at very competitive prices with other materials.

Veneer plywood is easy to work with, which makes it a very popular choice for many woodworkers. The sheets are lightweight and have an elegant look that enhances the overall design of your project or application. It can be shaped into different forms using hand tools or mechanical equipment such as routers, saws, planers, and sanders.

Veneer plywood is also environmentally friendly, as it uses the byproducts created during other manufacturing processes such as sawmills and paper mills. The waste wood fibers are recycled into veneers that can be glued together to create a product with great resilience for high-impact loads or resistance to water damage. Veneer plywood is also able to resist chemicals, moisture, and temperature changes.

Veneer plywood can be used for many projects at home or work. It’s often chosen by woodworkers because of the great design opportunities it provides with its thin but strong sheets that are easy to cut, bend and shape into different forms using hand tools or mechanical equipment such as routers, saws, planers, and sanders.

Veneer plywood can be used to create projects such as cabinets or furniture pieces that require a lightweight yet strong material to support the weight of objects placed on top during use. It’s also chosen for its high strength-to-weight ratio, which is one of its biggest benefits over solid lumber.

For smaller projects, veneer plywood can be used to create signs or even photo frames that would otherwise need thicker materials like particleboard which adds extra weight and bulkiness. The thin sheets are also easy to cut into different shapes for your project’s needs, making it possible to fit them around obstacles such as pipes or electrical outlets.

Veneer plywood is also used for many other projects that require lightweight yet strong panels with a smooth surface to provide an elegant look and feel to your project. This includes applications such as architectural elements like flooring, staircases, furniture components, or any panel product where you need the material’s sturdiness without its bulkiness.

Homemade Veneer Press to Laminate Your Own Plywood Panels

Subscribe to Newton Makes on Youtube

How Do You Apply Plywood Veneers?

Plywood is a composite material that consists of many layers. Veneer plywood, one type of plywood, has sheets (veneers) that are thinner than the standard thickness and glued together into panels. The veneers used in veneer plywoods may be thin or thick; it depends on the specific properties you are looking for. The more layers are used, the higher the quality of plywood that you have to work with.

Can You Veneer Just One Side Of Plywood?

No. Veneer plywood has veneers on both sides of the panel, which is why you cannot apply it to just one side of your project. If you only want the decorating surface exposed, consider using solid wood instead of veneer plywood for this reason.

How Do You Get Plywood Veneer Strips?

You can have plywood veneers cut for you or purchase them in large sheets so that you do not need to worry about working with smaller pieces. For example, if your project requires a thicker piece of wood than the standard size, it is better to buy a thicker sheet of veneer plywood than normal.

Is Veneer Plywood Expensive?

Yes, it can be expensive if you are looking for a very large piece or one that has been specially designed to meet your unique needs or requirements. However, generally speaking, the cost will not differ much from what you would pay for a similar sheet of solid wood.

Veneer Plywood is an ideal product that can be used on many different projects. It gives you the same quality as regular plywood, but it comes with veneers attached to both sides, which makes it look more appealing. If you are looking for something simple yet elegant, try veneer plywood!

How to Apply Edge Banding Veneer to Plywood

Subscribe to TheLittleWoodHouse on Youtube

How Do You Veneer Plywood Edges?

You can attach veneer plywood edges to other pieces of veneer or solid wood using an adhesive. The most common types are thin and thick, but there is also a standard size you should know about if you’re hoping to get your project done quickly.

• First, cut the veneer piece so it will be the same size as your project’s plywood.

• Then, glue it to another piece of wood or veneer using a thin layer of adhesive at every joint. Press each edge firmly with clamps immediately after gluing them together so that you can prevent any warping from occurring during this step.

• Veneer is an extremely thin piece of wood, so it’s important that you have a thick layer of adhesive beneath the veneer for stability.

• Once your first edge is glued together and set in clamps, try to keep everything as flat as possible while gluing on additional pieces. It will be much harder to flatten out any irregularities or warping if you add more pieces on top of the already glued ones.

• If your veneer has a standard size, such as 24 by 48 inches or 30 by 60 centimeters, that is helpful because it can be cut quickly and precisely with either a miter box or a table saw. Just remember to always double-check for any markings before cutting to avoid mistakes.

• It’s also possible to cut the pieces of veneer down if they are too large for your project by using a circular saw or jigsaw, but this step will require more care and precision because you don’t want any gaps between the individual plywood pieces.

By following these steps, attaching edges is easy and can be done quickly.

Veneer Plywood Properties

- Versatile

Veneer plywood is one of the most versatile types of wood used in cabinetry, furniture-making, and other construction projects. It’s also known as “veneer faced plywood,” but it goes beyond just being a pretty face for your project. Veneered plywood offers great variety while still providing quality wood material.

Veneer plywood is versatile because it can be used for both interior and exterior applications, as well as tall pieces of cabinets or furniture. It’s also a great choice when you want to use a specific veneer on one side but not the other—for example, if you have an exotic wood you want to use on the outside of a box but not for the inside.

- Multiple Layers

Each piece of veneer plywood is made up of three or more layers that are combined under heat and pressure into one sheet. The innermost layer (or “core”) can be soft or hard, depending on the type of wood and how it’s made. The two outer layers (the “veneers”) are thin sheets of wood that can be used by themselves or combined with other veneers to create a unique pattern.

- Multiple Thickness

Veneer plywood is available in various thicknesses, including ½ inches and ¾ inches, as well as in standard lengths of eight feet. Common thicknesses for plywood are ¼ inch, ½ inches, and ¾ inches.

The veneer used in the outer layers is typically a finer quality than that used in the core layer, which means it can add beauty to your woodworking projects while also providing structural support when needed. The outside veneers are typically made from birch or other types of wood that can be stained or painted to create whatever color you need. The core layer is usually poplar, which is cost-effective and easy to work with.

What kind of plywood do you use?

Subscribe to Steve Ramsey Plus on Youtube