Pocket hole joinery is a popular method of joining wood pieces together. It is a simple technique that involves drilling a hole at an angle through one board and into another, then driving a screw into the pocket hole to hold the two pieces together. One common question that arises when using pocket holes is whether the hole is supposed to go all the way through the wood.

The answer to this question is that it depends on the situation. According to a post on Woodworking Talk, drilling all the way through the wood can result in raised fibers around the exit hole area, which may require sanding or carving to smooth out. However, if the joint requires a through-hole, then drilling all the way through is necessary. As a general rule, pocket holes are designed to be drilled only partway through the wood, leaving enough material for the screw threads to grip onto.

Understanding pocket holes and the tools and materials required for pocket hole joinery is essential to properly executing this technique. Knowing when to drill through and when to stop short is an important aspect of the process. With the right tools and knowledge, pocket hole joinery can be a reliable and efficient method of joining wood pieces together.

Table of Contents

Key Takeaways

- Pocket holes are not always supposed to go all the way through the wood.

- Drilling all the way through can result in raised fibers around the exit hole area.

- Understanding the pocket hole joinery process and when to drill through is crucial for successful execution.

Understanding Pocket Holes

Pocket hole joinery is a popular method of joining two pieces of wood together. It involves drilling a pocket hole at an angle into one of the pieces of wood and then attaching it to the other piece with a screw. The pocket hole is a simple and effective way to create a strong joint between two pieces of wood.

A pocket hole is not supposed to go all the way through the wood. Instead, it should only go partway into the wood, leaving a small amount of material on the other side. This is because the pocket hole is designed to create a strong joint by pulling the two pieces of wood together. If the hole goes all the way through the wood, it will not create a strong joint and may even split the wood.

To create a pocket hole, a pocket hole jig is used. A pocket hole jig is a tool that helps guide the drill bit at the correct angle to create the pocket hole. The jig also helps to ensure that the pocket hole is positioned in the correct location on the wood.

Pocket hole screws are specifically designed for use with pocket hole joinery. These screws have a special shape that helps to pull the two pieces of wood together tightly. They also have a self-tapping feature that allows them to be driven into the wood without the need for a pilot hole.

When using a pocket hole jig, it is important to pay attention to the thickness of the wood being used. The thickness of the wood will determine the length of the pocket hole screw that should be used. The thickness of the wood will also determine the spacing between the pocket holes.

In summary, a pocket hole is not supposed to go all the way through the wood. Pocket hole joinery is a simple and effective way to create a strong joint between two pieces of wood. A pocket hole jig and pocket hole screws are essential tools for creating pocket holes. When using a pocket hole jig, it is important to pay attention to the thickness of the wood being used to ensure the correct screw length and spacing between pocket holes.

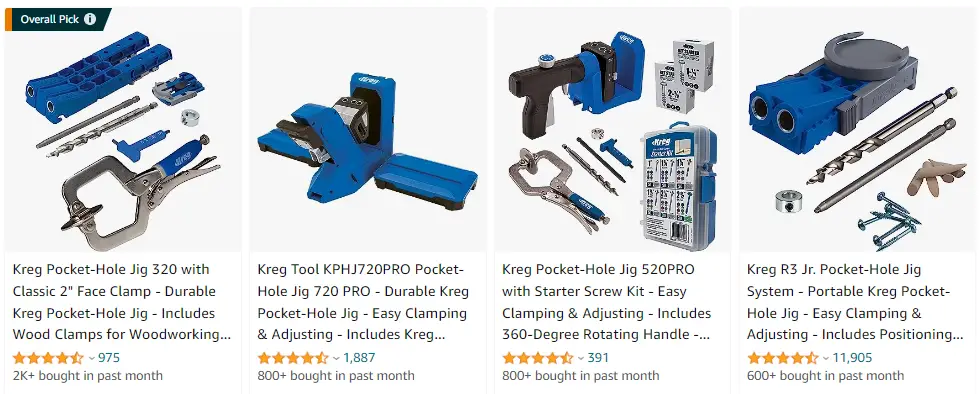

Kreg Pocket Hole Jigs

Click Here To Check The Prices On Amazon

Tools and Materials

Essential Tools

When it comes to pocket hole joinery, there are a few essential tools that you will need to get started. These include a pocket hole jig, a stepped drill bit, and a driver bit. The pocket hole jig is used to drill the angled pilot hole into the wood, while the stepped drill bit creates the pocket for the screw to fit into. The driver bit is used to drive the screw into the pocket hole.

Required Materials

In addition to the essential tools, there are also some required materials that you will need to complete your pocket hole joinery project. These include wood screws, clamps, and wood glue. The wood screws are used to secure the joint, while the clamps are used to hold the pieces of wood together while the glue dries.

It is important to select the right type of screws for your project. Self-tapping screws are a good choice for softer woods, while coarse screws are better suited for hardwoods. Fine screws are a good choice for thinner boards, as they are less likely to split the wood.

When selecting wood glue, it is important to choose a high-quality product that will provide a strong bond. It is also important to consider the wood movement when selecting glue.

Pocket Hole Plugs

Pocket hole plugs can be used to cover up the screw holes in your project, giving it a more finished appearance. They are available in a variety of wood species and can be sanded and stained to match the rest of the project.

Kreg Pocket-Hole Screws

Kreg pocket-hole screws are specifically designed for use with pocket hole joinery. They are available in a variety of sizes and finishes, and are designed to provide strong, durable joints.

Screw Selector Tool

Kreg offers a screw selector tool that can help you choose the right screw for your project. Simply select the type of wood you are working with, the thickness of the wood, and the joint type, and the tool will recommend the appropriate screw size and length.

Pocket Hole Jig

The Kreg pocket hole jig is a popular tool used for pocket hole joinery. It features a clamping system that holds the wood in place while the angled pilot hole is drilled. The jig also features an alignment guide that helps ensure accurate hole placement.

Other Considerations

When working with pocket hole joinery, it is important to consider the wood grain and the direction of the wood fibers. Butt joints, where the end grain of one piece of wood is joined to the face grain of another, are not as strong as edge grain joints.

It is also important to consider the structural strength of the joint. While pocket hole joinery is a strong joinery technique, it may not be suitable for all applications. For example, it may not be strong enough for structural frames or cabinet face frames.

Overall, pocket hole joinery is a versatile and easy-to-use joinery technique that can be used for a wide range of woodworking projects. With the right tools and materials, it is possible to create strong, durable joints that will stand the test of time.

Pocket Hole Joinery Process

Pocket hole joinery is a popular woodworking technique that allows for fast, strong, and accurate joining of wood pieces. The process involves drilling a pocket hole at an angle into one piece of wood and then joining it to another with a pocket screw. Here is a breakdown of the pocket hole joinery process.

Preparation

To begin with pocket hole joinery, you need a pocket hole jig, a stepped drill bit, a stop collar, and pocket hole screws. The pocket hole jig is used to guide the drill bit at the correct angle and depth. The stepped drill bit is designed to drill a pilot hole and a larger hole for the screw head. The stop collar is used to set the depth of the drill bit. Pocket hole screws come in various sizes and lengths, and it is important to choose the right size for the wood thickness.

Drilling

The first step in the pocket hole joinery process is drilling the pocket holes. The wood pieces to be joined should be clamped securely to the workbench or a jig. The pocket hole jig is then positioned on the wood, and the drill bit is inserted into the guide hole. The drill bit is then driven into the wood until the stop collar hits the jig. The drill bit is then removed, and the wood piece is ready for assembly.

Assembly

The final step is to assemble the wood pieces with pocket screws. The wood pieces are first aligned and clamped together. Pocket screws are then inserted into the pocket holes and driven into the wood with a screwdriver or drill. It is important to apply glue to the joint before driving in the screws to ensure a strong bond.

It is also important to consider wood movement when using pocket hole joinery. The orientation and alignment of the wood pieces can affect how they expand and contract with changes in humidity. Dowels can be used to reinforce the joint and prevent disassembly.

Pocket hole joinery is suitable for a variety of woodworking projects, including structural frames, cabinet face frames, bookcases, and furniture building. It is versatile and can be used with both hardwoods and softwoods. The joint is strong and can withstand stresses, but it is important to use the right screw size and hole spacing for the wood thickness. Pocket hole plugs can be used to cover the screw holes and improve the appearance of the joint.

In summary, pocket hole joinery is a fast, strong, and versatile woodworking technique that can be used for a variety of projects. It involves drilling pocket holes at an angle, aligning and clamping the wood pieces, and driving in pocket screws. With the right tools and techniques, pocket hole joinery can produce durable and attractive joints.

Applications of Pocket Hole Joinery

Pocket hole joinery is a versatile technique that can be used for a variety of woodworking projects. It is often used in furniture building, cabinets, and other joinery techniques. Pocket hole joinery is an efficient and strong method of joining two pieces of wood together.

One of the primary applications of pocket hole joinery is in the construction of table tops and cabinet doors. These projects require strong joints that can withstand the weight of the tabletop or door. Pocket hole joinery creates a strong joint that can handle the weight and pressure of these projects.

Another application of pocket hole joinery is in the construction of workbenches and desks. These projects require strong joints that can withstand the weight and pressure of heavy use. Pocket hole joinery creates a strong joint that can handle the weight and pressure of these projects.

Mitered corners can also benefit from pocket hole joinery. Pocket holes can be used to reinforce the mitered joint, creating a strong and durable joint that will hold up over time.

Pocket hole joinery can also be used in the construction of structural frames for cabinets, bookcases, and other furniture building projects. Pocket holes can be used to reinforce the joints, creating a strong and durable frame that will hold up over time.

When using pocket hole joinery, it is important to consider the type of wood being used. Hardwoods and thinner boards may require different screw sizes and hole placements than softwoods and thicker boards. Coarse screws are typically used for softwoods, while fine screws are used for hardwoods.

Overall, pocket hole joinery is a versatile and efficient method of joining two pieces of wood together. It can be used in a variety of woodworking projects, from picture frames to outdoor projects. With the right pocket hole jig and screws, pocket hole joinery can create a strong joint that will hold up over time.

Troubleshooting Common Issues

When using pocket holes, there are a few common issues that woodworkers might encounter. Here are some tips to help troubleshoot these issues:

Splitting Wood

One of the most common issues with pocket hole joinery is splitting wood. This can happen when the pocket hole is too close to the edge of the board or when using hardwoods. To prevent splitting, make sure to use the correct screw size and pilot hole. Also, avoid placing pocket holes too close to the edge of the board. If you need to place a pocket hole near the edge, consider using a pocket hole plug to cover the hole and improve the appearance of the joint.

Weak Joints

Another issue that can occur with pocket holes is weak joints. This can happen when using the wrong screw size or when not clamping the joint tightly enough. To ensure a strong joint, use the correct screw size and make sure to clamp the joint tightly before driving the screws. Additionally, consider using a Kreg pocket-hole screw selector tool to choose the correct screw for your project.

Appearance Issues

Pocket holes can also create appearance issues if not done correctly. For example, if the pocket hole is not drilled at the correct angle or depth, it can create a gap between the two boards. To avoid this, use a Kreg pocket hole jig and drill bit to ensure that the pocket hole is drilled at the correct angle and depth. Additionally, consider sanding the joint after assembly to improve the appearance.

Wood Movement

Finally, wood movement can also be an issue with pocket hole joinery. This is especially true when using thinner boards or when working with hardwoods. To prevent wood movement, consider using a Kreg clamping system to hold the joint in place while driving the screws. Additionally, consider using a mitered joint or a different type of joint that allows for wood movement.

By following these tips, woodworkers can troubleshoot common issues with pocket hole joinery and create strong, reliable joints for their projects.

Frequently Asked Questions

Can pocket holes be used on beveled edges?

Yes, pocket holes can be used on beveled edges, but you need to take some precautions. You should clamp the board securely to the work surface, and make sure that the pocket hole jig is properly aligned. It’s also important to use the right size of drill bit and screw, and to drill the pocket hole at the correct angle.

What is the maximum depth for a pocket screw?

The maximum depth for a pocket screw is about 1 1/2 inches. If you try to use a longer screw, it may poke through the other side of the wood, or it may not hold the joint securely. It’s important to choose the right size of screw for the thickness of the wood you’re using, and to drill the pocket hole to the correct depth.

How do I prevent pocket hole screws from sticking out?

To prevent pocket hole screws from sticking out, you should use the right size of screw for the thickness of the wood you’re using, and drill the pocket hole to the correct depth. You should also make sure that the screw is not over-tightened, as this can cause it to pull through the wood and create a bump on the surface. If the screw does stick out slightly, you can use a chisel or sandpaper to remove the excess.

When should I use pocket holes?

Pocket holes are a versatile and easy-to-use method of joinery that can be used in a variety of woodworking projects. They’re especially useful for joining boards at right angles, such as when building cabinets, bookcases, or tables. Pocket holes can also be used to join boards at an angle, such as when building a picture frame or a chair. However, pocket holes may not be suitable for every project, and it’s important to consider the strength and appearance of the joint before deciding to use them.