Kreg screws are an essential component of the Kreg pocket-hole system. They are used to create strong, hidden joints in woodworking projects. There are many different types and sizes of Kreg screws available, each designed for specific applications. In this article, we will discuss the most common Kreg screws and their uses.

Understanding Kreg Screws Kreg screws are specially designed screws that are used with the Kreg pocket-hole jig. They are self-tapping screws that have a flat-bottomed head and a deep thread. The thread is designed to grip the wood tightly and pull the joint together as the screw is driven in. The flat-bottomed head is designed to sit flush with the surface of the wood, creating a clean, finished look.

Types of Kreg Screws There are several different types of Kreg screws available, each designed for specific applications. The most common types of Kreg screws include coarse-thread screws, fine-thread screws, and washer-head screws. Coarse-thread screws are designed for use with softwoods, while fine-thread screws are designed for use with hardwoods. Washer-head screws are designed for use with plywood and other sheet goods.

Understanding Kreg Screws

Kreg screws are specially designed screws used for pocket-hole joinery. They are self-tapping screws that can be used in a variety of materials, including wood, MDF, and particleboard. These screws have a unique design that allows them to be used with Kreg jigs to create strong, hidden joints.

Types of Kreg Screws

Kreg screws come in various types, each designed for specific applications. The most common types of Kreg screws are:

- Pan-Head Screws: These screws have a flat underside and a rounded top. They are used for general-purpose pocket-hole joinery.

- Maxi-Loc Screws: These screws have a washer head that provides extra holding power. They are used for thicker materials and outdoor projects.

- Fine-Thread Screws: These screws have a finer thread than other Kreg screws. They are used for hardwoods and other dense materials.

- Coarse-Thread Screws: These screws have a coarse thread that provides more holding power. They are used for softwoods and other less dense materials.

Head Styles

Kreg screws come in two head styles: pan head and washer head. Pan head screws are the most common and are used for general-purpose pocket-hole joinery. Washer head screws provide extra holding power and are used for thicker materials and outdoor projects.

Self-Tapping Tip

Kreg screws have a self-tapping tip that makes it easy to drill a pocket hole and drive the screw in one step. This tip eliminates the need for pre-drilling and reduces the risk of splitting the wood.

Steel

Kreg screws are made of high-quality steel that provides strength and durability. The steel is specially hardened to prevent the screw from snapping or breaking during installation.

In summary, Kreg screws are specially designed screws used for pocket-hole joinery. They come in various types and head styles, have a self-tapping tip, and are made of high-quality steel. By understanding the different types of Kreg screws and their applications, you can choose the right screw for your project and create strong, hidden joints.

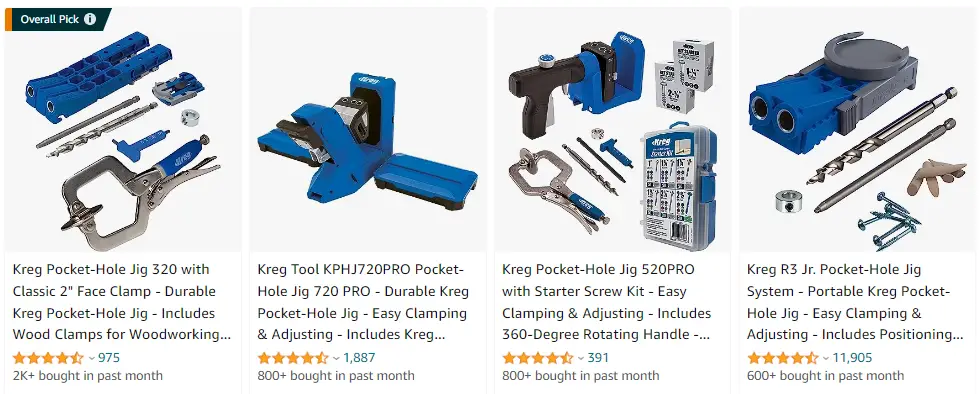

Kreg Pocket Hole Jigs

Click Here To Check The Prices On Amazon

Types of Kreg Screws

Kreg screws come in different types, each designed for specific applications. Here are the most common types of Kreg screws:

Coarse-Thread Screws

Coarse-thread screws are designed for softwoods, such as pine, cedar, and fir. They have a deep, aggressive thread that provides a strong hold in soft materials. Coarse-thread screws are available in different lengths, ranging from 1 inch to 2-1/2 inches. They are also available in different finishes, including zinc-coated, blue-kote™, and stainless steel.

Fine-Thread Screws

Fine-thread screws are designed for hardwoods, such as oak, maple, and cherry. They have a finer thread that provides a smoother, tighter hold in hard materials. Fine-thread screws are available in different lengths, ranging from 1 inch to 2-1/2 inches. They are also available in different finishes, including zinc-coated, blue-kote™, and stainless steel.

Specialty Kreg Screws

In addition to coarse-thread and fine-thread screws, Kreg also offers specialty screws for specific applications. Here are some examples:

- Zinc-coated Kreg pocket-hole screws: These screws have a zinc coating that provides extra protection against rust and corrosion. They are ideal for indoor projects.

- Blue-kote™ Kreg pocket-hole screws: These screws have a blue-kote™ finish that provides extra protection against corrosion and wear. They are ideal for outdoor projects.

- Stainless steel Kreg pocket-hole screws: These screws are made of stainless steel, which provides excellent resistance to rust and corrosion. They are ideal for projects that will be exposed to moisture or saltwater.

- Drywall screws: These screws are designed for use with Kreg’s drywall pocket-hole jig. They have a special thread that provides a strong hold in drywall.

- Maxi-loc screws: These screws have a larger washer head that provides extra holding power. They are ideal for use in hardwoods and composites.

Overall, Kreg screws are designed to provide a strong, secure hold in a variety of materials. By choosing the right type of screw for your project, you can ensure that your joints will be strong and durable.

Choosing the Right Kreg Screw

When it comes to choosing the right Kreg screw, there are several factors to consider. These include the material type, material thickness, and the location of the project (indoors or outdoors).

Kreg screws come in different lengths, ranging from 1 inch to 2.5 inches. The length of the screw you choose will depend on the thickness of the material you are using. It is important to note that the thickness of the material may not be the same as its nominal thickness. For example, a board labeled as 1 inch thick may actually measure 3/4 inch in actual thickness. It is important to measure the actual thickness of the material to choose the appropriate screw length.

Kreg offers a screw selector tool that can help you choose the right screw for your project. The tool takes into account the material type, material thickness, and the type of Kreg jig you are using. You can also use a screw selection chart or a screw selector wheel to choose the right screw length.

In general, coarse-thread screws are recommended for softwoods like pine, cedar, and fir, while fine-thread screws are preferred for hardwoods like cherry, maple, and oak. Coarse-thread screws are more aggressive and can help prevent splitting, while fine-thread screws offer better holding power.

It is important to note that Kreg screws are designed to work specifically with Kreg jigs. Using other types of screws may not provide the same strong, reliable joint.

Overall, choosing the right Kreg screw can make a big difference in the strength and durability of your project. By taking into account the material type, material thickness, and location of the project, you can select the appropriate screw length and type for your needs.

Kreg Screws for Different Materials

When it comes to Kreg screws, choosing the right one for your project can be crucial. One of the most important factors to consider is the material you will be working with. Here are some common materials and the Kreg screws that work best with them:

Softwoods

Softwoods such as cedar, pine, and fir are common materials for outdoor projects. For softwoods, it is recommended to use Kreg’s Blue-Kote screws. These screws are specially designed for use in outdoor projects and are highly resistant to corrosion and rust.

Hardwoods

Hardwoods like maple and oak are commonly used in furniture and other indoor projects. For these materials, Kreg’s Stainless Steel screws are the best choice. These screws are highly resistant to corrosion and rust, making them ideal for indoor projects that require long-lasting strength and durability.

Sheet Goods and Plywood

Sheet goods and plywood are commonly used in woodworking projects. For these materials, Kreg’s Fine thread Pocket-Hole screws are the best choice. These screws have a fine thread design that helps prevent splitting and provide a strong, secure hold.

Treated Lumber

Treated lumber is often used in outdoor projects, such as decks and fences. For treated lumber, Kreg’s Blue-Kote screws are the best choice. These screws are specially designed to resist corrosion and rust and are ideal for use in outdoor projects.

MDF

MDF is a popular material for indoor projects, such as cabinets and shelving. For MDF, Kreg’s Coarse thread Pocket-Hole screws are the best choice. These screws have a coarse thread design that provides a strong, secure hold in MDF and other similar materials.

In summary, choosing the right Kreg screw for your project can be critical. By considering the material you will be working with, you can ensure that you choose the right screw for the job.

Kreg Screws for Indoor and Outdoor Projects

Kreg screws are available in different types and sizes, each designed for specific applications. When choosing the right Kreg screw, it’s important to consider the type of project, whether it will be used indoors or outdoors, and the type of material being used.

For indoor projects, zinc-coated screws are a popular choice. They are resistant to corrosion and rust, making them ideal for use in dry indoor environments. Zinc-coated screws are available in different sizes and thread types, so it’s important to choose the right one based on the thickness of the material being used.

For outdoor projects, it’s important to use screws that can withstand exposure to moisture and the elements. Blue-Kote™ screws are a great option for outdoor projects as they are highly resistant to corrosion and rust. They are coated with a blue-kote finish that provides three times more rust resistance than standard zinc-plated screws. Blue-Kote™ screws are available in different sizes and thread types, making it easy to find the right one for your project.

When choosing Kreg screws for indoor or outdoor projects, it’s important to consider the type of material being used. Softwood, hardwood, or plywood all require different types of screws. Coarse thread screws are ideal for softwood, while fine thread screws are better suited for hardwood and plywood. It’s important to choose the right thread type to ensure a strong and secure joint.

In summary, Kreg screws come in different sizes and types for various applications. Zinc-coated screws are ideal for indoor projects, while Blue-Kote™ screws are perfect for outdoor projects. When choosing the right screw, it’s important to consider the type of material being used and the thread type needed for a strong and secure joint.

Kreg Pocket-Hole System

The Kreg Pocket-Hole System is a popular method of joinery that uses pocket holes and screws to create strong and secure joints. This system is ideal for woodworking projects of all kinds, from simple DIY projects to more complex furniture builds.

The Kreg Pocket-Hole System consists of several key components, including the Kreg Jig, pocket-hole screws, and pocket-hole plugs. The Kreg Jig is a tool that helps you drill pocket holes at the correct angle and depth, while pocket-hole screws are specially designed screws that are used to secure the joint. Pocket-hole plugs are used to fill the pocket holes and create a seamless finish.

Kreg Pocket-Hole Screws come in a variety of sizes and styles to suit different projects. The most common sizes are 1″, 1-1/4″, 1-1/2″, 2″, and 2-1/2″. The size of the screw you choose will depend on the thickness of the material you are working with.

Kreg Pocket-Hole Screws are available in several different finishes, including zinc, stainless steel, and blue-kote. Zinc screws are the most common and are suitable for indoor use. Stainless steel screws are ideal for outdoor projects, as they are resistant to rust and corrosion. Blue-kote screws are coated with a blue anti-corrosion layer that provides extra protection against the elements.

Kreg Pocket-Hole Screws are also available in several different thread types, including coarse, fine, and Maxi-Loc. Coarse-thread screws are ideal for softwoods, while fine-thread screws are better suited for hardwoods. Maxi-Loc screws have a large head that provides maximum bearing surface and are suitable for a wide range of applications.

In addition to pocket-hole screws, Kreg also offers a range of other products to help you get the most out of your pocket-hole jig. These include pocket-hole clamps, which help to hold your workpiece securely in place while you drill the pocket holes, and pocket-hole plugs, which are used to fill the pocket holes and create a seamless finish.

Frequently Asked Questions

What kind of pocket screws for 3/4 plywood?

When using 3/4 inch plywood, it is recommended to use 1-1/4 inch coarse thread pocket screws. These screws are specifically designed for use with plywood and will provide a strong and secure joint.

What is the difference between Kreg screws #7 and #8?

The main difference between Kreg screws #7 and #8 is the size. #7 screws are 1-1/4 inches long, while #8 screws are 2-1/2 inches long. Additionally, #8 screws have a larger diameter than #7 screws, which makes them stronger and more suitable for larger projects.

Where can I find a Kreg screw chart in PDF format?

Kreg offers a screw length selection chart in PDF format on their website. This chart can be found at www.kregtool.com. The chart provides a guide for selecting the correct screw length based on the thickness of the material being used.