Woodworking is a popular hobby for many people. Whether you’re building a piece of furniture or simply making repairs around the house, having the right tools is essential. One tool that is often used in woodworking is a Kreg jig. This handy device allows you to join pieces of wood together quickly and easily. But how thick does the wood have to be to use a Kreg jig?

A Kreg jig is a tool that is used to create pocket holes in wood. These pocket holes allow you to join two pieces of wood together without the need for dowels or other fasteners. The Kreg jig is designed to work with a variety of wood thicknesses, from 1/2 inch to 1-1/2 inches. However, it’s important to note that the thickness of the wood will determine the settings you need to use on your Kreg jig.

To use a Kreg jig, you’ll need to set the depth collar on your drill bit to the appropriate level for the thickness of the wood you’re working with. The Kreg jig comes with a material thickness gauge that makes it easy to determine the correct depth collar setting. Once you’ve set your drill bit to the correct depth, you can begin drilling pocket holes in your wood.

Key Takeaways

- A Kreg jig is a tool used to create pocket holes in wood.

- The Kreg jig is designed to work with a variety of wood thicknesses, from 1/2 inch to 1-1/2 inches.

- To use a Kreg jig, you’ll need to set the depth collar on your drill bit to the appropriate level for the thickness of the wood you’re working with.

What is a Kreg Jig

A Kreg Jig is a type of woodworking tool that allows the user to create pocket holes in wood. It is a popular tool for beginners in woodworking and DIY projects. The Kreg Jig is designed to make it easy for anyone to create strong, precise joints without the need for complicated and expensive woodworking equipment.

The Kreg Jig works by drilling a pocket hole at an angle into one piece of wood, and then joining it to another piece of wood with a self-tapping screw. The pocket hole is hidden from view, making it a great option for creating clean and professional-looking joints.

The Kreg Jig is available in a variety of models, including the Kreg Jig K4 and the Kreg Jig Jr. Each model is designed to work with different wood thicknesses and joint types, making it easy to find the right tool for the job.

Using a Kreg Jig is a simple process that involves setting the jig to the correct wood thickness, drilling the pocket hole, and then joining the two pieces of wood together with a screw. The Kreg Jig Settings Chart and Calculator can help users determine the correct jig setting and screw length for their specific project.

Overall, the Kreg Jig is a versatile and easy-to-use tool that is perfect for anyone looking to create strong and precise joints in their woodworking and DIY projects.

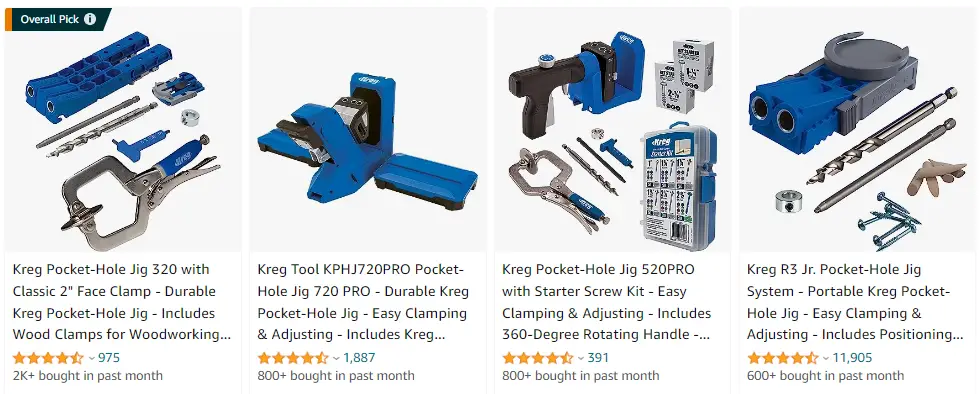

Kreg Pocket Hole Jigs

Click Here To Check The Prices On Amazon

Understanding Wood Thickness

When using a Kreg jig, it is important to understand the thickness of the wood you are working with. The thickness of the wood will determine the appropriate settings for the jig and drill bit.

Wood thickness is typically measured in inches and can range from 1/8 inch to several inches. The most common thicknesses for boards are 1/2 inch, 3/4 inch, and 1 inch. Plywood is also commonly used in woodworking projects and is available in a variety of thicknesses.

When joining two boards of the same thickness, the Kreg jig can be set up using the thickness of the boards. However, when joining boards of different thicknesses, it is important to consider the thickness of the thinnest board.

For example, if you are joining a 3/4 inch board to a 1/2 inch board, you should set the Kreg jig to the thickness of the 1/2 inch board. This will ensure that the pocket holes are drilled at the correct angle and depth for the thinner board.

It is also important to note that the type of wood can affect the appropriate settings for the Kreg jig. Hardwoods, such as oak and maple, may require different settings than softwoods, such as pine and cedar.

In addition, the thickness of plywood can vary depending on the number of layers and the type of wood used. It is important to measure the thickness of the plywood before setting up the Kreg jig.

Overall, understanding wood thickness is crucial when using a Kreg jig. By taking into account the thickness of the wood and the type of wood being used, you can ensure that your pocket holes are drilled accurately and securely.

The Role of the Kreg Jig

The Kreg Jig is a popular tool among woodworkers for creating strong joints in furniture and other DIY projects. It is a tool that allows you to drill pocket holes, which are angled holes that allow you to join two pieces of wood together with a screw.

One of the main benefits of using a Kreg Jig is that it creates a strong joint. The pocket hole allows the screw to be driven through the side of the wood and into the end grain of the other piece, creating a strong mechanical connection. This type of joint is much stronger than a butt joint, which simply relies on glue to hold the two pieces of wood together.

Another benefit of using a Kreg Jig is that it allows you to create these strong joints quickly and easily. The Kreg Jig has a drill guide that ensures that the pocket hole is drilled at the correct angle and depth every time. This means that you can create multiple pocket holes quickly and accurately, which is especially useful if you are building a large piece of furniture.

When using a Kreg Jig, it is important to use the correct wood thickness. The Kreg Jig comes with a material thickness gauge that allows you to check the thickness of your wood. This is important because the length of the screw you use will depend on the thickness of your wood. Using the wrong length screw can result in a weak joint or even damage to your project.

Overall, the Kreg Jig is an essential tool for anyone who wants to create strong joints in their DIY furniture projects. It allows you to create pocket holes quickly and accurately, resulting in strong mechanical connections between pieces of wood. By using the correct wood thickness and screw length, you can ensure that your joints are strong and durable.

Kreg Jig Settings

When using a Kreg Jig, it is important to set it up correctly to ensure a strong and secure joint. The correct settings will depend on the thickness of the wood you are using and the type of joint you want to create.

The Kreg Jig Settings Chart and Calculator on Industry DIY provides a helpful tool for selecting the correct jig setting and screw length based on the thickness of your wood. To use the chart, you simply select the units, joint type, and wood thickness, and the chart will provide the suggested jig setting and screw length.

In addition to the Kreg Jig Settings Chart, it is also important to set the correct depth collar on your drill bit. The depth collar controls the depth of the pocket hole and ensures that the screw is driven in at the correct angle. The Kreg Jig Depth Collar Settings Guide on Pine and Poplar provides a free chart that shows the correct depth collar setting for different wood thicknesses.

When joining two different thicknesses of boards, it is important to use the correct settings to ensure a strong joint. The Kreg Owners’ Community on Ning provides a discussion on the correct settings for joining different thicknesses of boards using a Kreg Jig.

Overall, setting up your Kreg Jig correctly is essential to creating a strong and secure joint. By using the correct jig setting, screw length, and depth collar setting, you can ensure that your pocket holes are drilled at the correct angle and depth for a strong and secure joint.

Drilling with the Kreg Jig

When using a Kreg Jig, it is important to drill the correct holes in the wood to ensure a secure joint. The Kreg Jig comes with a drill bit and drill guide that are specifically designed to create pocket holes at the correct angle and depth.

Before drilling, it is recommended to pre-drill the wood to prevent splitting. This is especially important when working with hardwoods or thin pieces of wood. To pre-drill, simply drill a small hole into the wood at the location where the pocket hole will be drilled. This will allow the pocket hole screw to go in smoothly and prevent the wood from splitting.

To drill the pocket hole, insert the drill bit into the drill guide and adjust the collar to the correct depth. The depth collar setting will depend on the thickness of the wood being used. The Kreg Jig Settings Chart and Calculator can be used to determine the correct settings for different wood thicknesses.

Once the drill bit is set to the correct depth, clamp the Kreg Jig onto the wood and drill the pocket hole. The drill guide will ensure that the hole is drilled at the correct angle and the depth collar will ensure that the hole is drilled to the correct depth.

After drilling the pocket hole, insert the pocket hole screw into the hole and tighten it using a drill or driver. The screw will pull the two pieces of wood together, creating a strong joint.

Overall, drilling with the Kreg Jig is a simple and effective way to create strong, secure joints in wood. By following the recommended settings and pre-drilling when necessary, users can achieve professional results with ease.

Using a Clamp with the Kreg Jig

When using the Kreg Jig, it is important to keep the wood in place while drilling the pocket holes. One way to do this is by using a clamp. The clamp will securely hold the wood in place, ensuring that the pocket holes are drilled in the correct location.

There are a few different types of clamps that can be used with the Kreg Jig. The Kreg Wood Project Clamp is a popular option that is specifically designed to work with the jig. This clamp slides into the T-slot recess on the back of the drill guide and locks in place with the end stop.

F-style clamps and C-clamps can also be used with the Kreg Jig. When using these clamps, simply install the end stop to prevent the clamp from sliding out of position. It is important to note that these clamps do not lock onto the drill guide like the Kreg Wood Project Clamp does.

When using a clamp with the Kreg Jig, it is important to make sure that the clamp is positioned correctly. The clamp should be positioned so that it is not in the way of the drill bit or the drill guide. It should also be positioned so that it is not putting too much pressure on the wood, which could cause it to warp or bend.

Overall, using a clamp with the Kreg Jig can help to ensure that your pocket holes are drilled accurately and securely. Whether you choose to use the Kreg Wood Project Clamp or another type of clamp, make sure that it is positioned correctly and is holding the wood securely in place.

Working with Different Material Thicknesses

When working with a Kreg jig, it’s important to consider the thickness of the wood you’re using. The Kreg jig is designed to work with a wide range of material thicknesses, from 1/2″ to 1-1/2″. However, when joining different thicknesses of wood, it’s important to adjust the Kreg jig settings accordingly.

To determine the correct settings for your Kreg jig, first, take note of the thickness of your wood. Set the depth collar bit to match the thickness of your wood. For example, if you’re using 3/4″ thick wood, set the depth collar bit to 3/4″.

Next, adjust the Kreg jig placement based on the thickness of your wood. The Kreg jig has a chart that shows the recommended settings for different material thicknesses. Simply find the thickness of your wood on the chart and adjust the jig accordingly.

When joining thicker material, it’s important to use a longer screw to ensure a secure joint. The Kreg jig chart also provides a recommended screw length based on the thickness of your wood. Be sure to use the correct screw length for the thickness of your wood to ensure a strong joint.

In summary, when working with different material thicknesses, adjust the Kreg jig settings to match the thickness of your wood and use the recommended screw length for a secure joint. By following these simple steps, you can ensure that your Kreg jig projects are strong and durable.

Tools Needed for the Kreg Jig

To use a Kreg Jig, there are a few tools that are necessary. These tools include an Allen wrench, a hex wrench, and a depth gauge.

Allen Wrench

The Allen wrench is used to adjust the depth collar on the drill bit. The depth collar determines how deep the pocket hole will be drilled. The Kreg Jig comes with an Allen wrench that has labels for ½”, ¾”, and 1.5″. These labels correspond to the thickness of the wood being used. To use the Allen wrench, place it up against the side of the Kreg Jig and turn it until the label for the desired wood thickness is facing up.

Hex Wrench

The hex wrench is used to tighten the drill bit into the Kreg Jig. To use the hex wrench, insert the drill bit into the Kreg Jig and tighten it using the hex wrench. It is important to make sure that the drill bit is tightened securely before drilling the pocket hole.

Depth Gauge

The depth gauge is used to measure the thickness of the wood being used. This is important because it determines the depth collar setting on the drill bit. The Kreg Jig comes with a material thickness gauge that can be used to measure the thickness of the wood. Simply hold the gauge up against the wood and determine which thickness number lines up with the wood. Then adjust the depth collar on the drill bit accordingly.

In addition to these tools, a drill is also necessary to use the Kreg Jig. It is important to use a drill with a clutch or depth stop to prevent over-drilling the pocket hole. Overall, with these tools and a drill, anyone can use a Kreg Jig to create strong and sturdy pocket holes in their woodworking projects.

Frequently Asked Questions

What is the minimum thickness of wood for Kreg pocket hole jig?

The minimum thickness of wood for Kreg pocket hole jig is 1/2 inch. The Kreg pocket hole jig is designed to work with materials that are at least 1/2 inch thick. If the wood is thinner than 1/2 inch, it may not be strong enough to hold the screws in place.

How to set Kreg Jig for 1/2 inch plywood?

To set up the Kreg Jig for 1/2 inch plywood, adjust the drill guide collar to 1/2 inch. Then, set the drill bit depth to 1-1/4 inches. Once the Kreg Jig is set up, place the plywood on the jig and clamp it in place. Drill the pocket holes in the desired locations.

What is the thinnest wood you can use with Kreg Jig?

The thinnest wood you can use with Kreg Jig is 1/2 inch. If the wood is thinner than 1/2 inch, it may not be strong enough to hold the screws in place. However, if you need to join thinner pieces of wood, you can use a different type of joinery method, such as glue or nails.

Kreg screw guide for different thicknesses?

Kreg screw guide is designed to work with different materials of varying thicknesses. Here are the material thicknesses for each range on the gauge:

- 1/2 inch range = 7/16 inch – 5/8 inch thick

- 3/4 inch range = 5/8 inch – 7/8 inch thick

- “I” range = 7/8 inch – 1 5/16 inch thick

- 1 1/2 inch range = 1 5/16 inch or thicker

Once you know the thickness of your material, you can use the Kreg screw guide to select the appropriate screw length. Using the right screw length ensures that the joint is strong and secure.