The Kreg Jig is a handy tool that allows you to join two pieces of wood together without the use of visible screws or nails. However, many people wonder if it’s possible to use a Kreg Jig on a 2×4. The good news is that the Kreg Jig can be used on a 2×4, and it’s actually a great tool to use for this type of project.

Understanding the Kreg Jig is the first step in using it on a 2×4. The Kreg Jig works by drilling pocket holes into the wood, which allows you to insert screws into the pocket holes to join two pieces of wood together. The pocket holes are drilled at an angle, which creates a strong joint that is hidden from view.

Using a Kreg Jig on a 2×4 is a simple process, but it does require some preparation. You’ll need to select the right screws, prepare your 2×4 for the Kreg Jig, and follow the process of joining 2x4s together. With the right tools and a little bit of practice, you can use a Kreg Jig to create strong, hidden joints in your 2×4 projects.

Key Takeaways

- The Kreg Jig can be used on a 2×4, and it’s a great tool for this type of project.

- Understanding the Kreg Jig is important before using it on a 2×4.

- Selecting the right screws, preparing your 2×4, and following the process of joining 2x4s together are essential steps in using a Kreg Jig on a 2×4.

Understanding the Kreg Jig

The Kreg Jig is a popular tool among woodworkers and DIY enthusiasts. It is a pocket hole jig that allows for quick and easy joinery of wood pieces. It works by drilling a pocket hole at an angle into one board and then joining it to another board with a screw.

The Kreg Jig is versatile and can be used on a variety of wood thicknesses, including 2x4s. It is designed to work with wood pieces that are 1/2 inch to 1-1/2 inches thick. For thicker wood pieces, longer screws can be used.

To use the Kreg Jig, the user needs to adjust the drill guide to match the thickness of the wood being used. The Kreg Jig comes with a chart that provides the recommended screw length for different wood thicknesses.

One of the benefits of using the Kreg Jig is that it creates a strong joint that is hidden from view. This makes it an ideal choice for projects where aesthetics are important, such as furniture or cabinetry.

In conclusion, the Kreg Jig is a versatile and easy-to-use tool for woodworking and DIY projects. It is designed to work with a variety of wood thicknesses, including 2x4s. With proper use and adjustment, it can create strong and hidden joints that are perfect for projects where aesthetics are important.

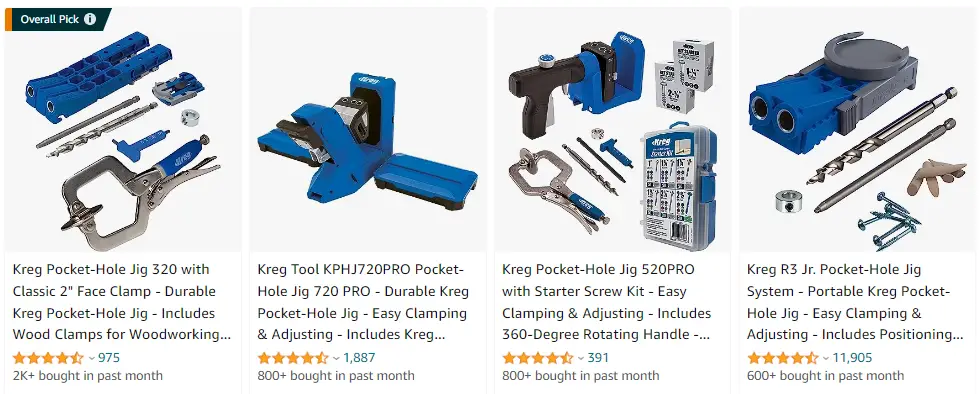

Kreg Pocket Hole Jigs

Click Here To Check The Prices On Amazon

Using Kreg Jig on a 2×4

When it comes to woodworking projects, 2x4s are a popular choice due to their affordability and versatility. If you’re wondering whether you can use a Kreg jig on a 2×4, the answer is yes! The Kreg jig is a versatile tool that can be used on a variety of materials, including 2x4s.

To use a Kreg jig on a 2×4, you need to set it up correctly. The ideal Kreg jig setting for a 2×4 is 1 1/2 inches. This is the thickness of a typical 2×4, so it’s important to check the material thickness before you begin.

When joining 2x4s with a Kreg jig, there are two types of joints you can use: butt joints and edge joints. Butt joints are used when you want to join the ends of two 2x4s together, while edge joints are used when you want to join the sides of two 2x4s together.

To create a butt joint, you will need to drill pocket holes into the end of each 2×4 using the Kreg jig. Then, you can use screws to join the two pieces together. When creating an edge joint, you will need to drill pocket holes into the side of each 2×4 and then join them together using screws.

It’s important to note that while the Kreg jig can be used on 2x4s, it may not be the best choice for all projects. For example, if you’re working with plywood or other materials that have a thinner thickness than 2x4s, you may need to adjust the Kreg jig settings accordingly.

In summary, the Kreg jig is a great tool for joining 2x4s together. By setting it up correctly and using the appropriate joints, you can create strong and durable connections for your woodworking projects.

Preparing Your 2×4 for the Kreg Jig

Before using a Kreg jig on a 2×4, it is important to prepare the wood properly. This will ensure that the joint is strong and secure. Here are the steps to follow:

Step 1: Clamp the 2×4

To prevent the wood from moving while drilling, it is important to clamp it securely. A clamp can be used to hold the 2×4 in place on a workbench or table. This will ensure that the wood remains stable while the holes are being drilled.

Step 2: Choose the Correct Drill Bit

The size of the drill bit used will depend on the thickness of the wood. For a 2×4, a 3/8-inch drill bit is recommended. This will create a hole that is the perfect size for the Kreg jig screw.

Step 3: Adjust the Collar on the Drill Bit

Before drilling, it is important to adjust the collar on the drill bit. This will ensure that the hole is the correct depth. The collar should be set to the thickness of the wood. For a 2×4, the collar should be set to 1 1/2 inches.

Step 4: Pre-Drill the Holes

To prevent the wood from splitting, it is important to pre-drill the holes. This can be done by drilling a small pilot hole first. This will make it easier to drill the larger hole without damaging the wood.

Step 5: Use a Stop Collar

A stop collar can be used to ensure that the holes are drilled to the correct depth. The collar can be adjusted to the correct depth and then locked in place. This will prevent the drill bit from going too deep and damaging the wood.

Step 6: Add Edge Banding (Optional)

If the joint will be visible, edge banding can be added to the 2×4. This will cover the exposed edges and create a more finished look. The edge banding can be applied using an iron or a docking station.

By following these steps, it is possible to use a Kreg jig on a 2×4. The joint will be strong and secure, and the finished product will look professional.

Selecting the Right Screws

When using a Kreg jig on a 2×4, it is important to select the right screws to ensure a secure joint. The type of screw you use will depend on the thickness of the material you are using, the type of wood, and where the project will be placed – indoors or outdoors.

Pocket-Hole Screws

Pocket-hole screws are specially designed for use with a Kreg jig. These screws have a self-tapping tip that drills its own pilot hole as it is driven into the wood. This makes it easy to create a strong joint with minimal effort.

Kreg Screws

Kreg screws are another type of screw that can be used with a Kreg jig. These screws have a square drive and a deep thread, which helps to prevent the screw from stripping out of the wood. Kreg screws come in a variety of lengths and diameters, so it is important to select the right size for your project.

Screw Length

The length of the screw you use will depend on the thickness of the material you are using. As a general rule, the screw should be long enough to go through the first piece of wood and at least halfway into the second piece of wood. For example, if you are joining two 2x4s together, the correct screw length would be 2.5 inches.

Pilot Hole

When using pocket-hole screws, it is important to drill a pilot hole before driving the screw into the wood. This helps to prevent the wood from splitting and ensures a strong joint. The size of the pilot hole will depend on the diameter of the screw you are using. Kreg provides a handy chart that lists the correct pilot hole size for each screw diameter.

In conclusion, selecting the right screws is crucial when using a Kreg jig on a 2×4. Pocket-hole screws and Kreg screws are both good options, and the correct screw length and pilot hole size will depend on the thickness of the material you are using. By following these guidelines, you can create strong, secure joints that will stand the test of time.

The Process of Joining 2x4s

Joining two 2x4s together is a common practice in woodworking projects. One way to do this is by using a Kreg pocket-hole jig. The Kreg pocket-hole jig is a tool that helps create strong and concealed joints by drilling angled guide holes for screws.

To join two 2x4s, the first step is to set up the Kreg pocket-hole jig according to the thickness of the wood. The Kreg jig has a chart that helps determine the appropriate settings for different wood thicknesses. Once the jig is set up, the next step is to clamp the wood securely to the workbench.

After clamping the wood, the Kreg jig is positioned on the wood where the pocket holes are desired. The jig has a drill guide that is used to drill the guide holes at the correct angle. The guide holes should be drilled at a spacing of about 6 inches apart.

When drilling the guide holes, it is important to keep the drill bit perpendicular to the wood surface. This ensures that the pocket holes are straight and the screws will go in smoothly.

After drilling the guide holes, the next step is to apply wood glue to the joint surfaces. This helps to strengthen the joint and prevent it from coming apart. Then, the two pieces of wood are clamped together using Kreg clamps or other clamps.

Finally, the screws are inserted into the guide holes and tightened using a drill. The Kreg pocket-hole jig XL can be used for extra holding power for larger projects built using 2×4 and 4×4 boards. The XL pocket-hole screws are longer and thicker than regular pocket-hole screws, providing extra strength for the joint.

In summary, joining two 2x4s using a Kreg pocket-hole jig involves setting up the jig, drilling guide holes at the correct angle and spacing, applying wood glue, clamping the wood together, and inserting screws. The Kreg pocket-hole jig XL can be used for extra holding power in larger projects.

Choosing the Right Wood for Your Project

When it comes to choosing the right wood for your project, there are several factors to consider. One of the most important factors is the type of wood you use. Softwoods like pine are a popular choice for many projects, including 2x4s. Pine is affordable, easy to work with, and readily available at most home centers. However, it is important to note that pine is not the most durable wood and may not hold up well in certain conditions.

Another popular choice for outdoor projects is cedar. Cedar is naturally resistant to decay and insects, making it a great choice for outdoor use. It also has a beautiful appearance and can be left unfinished or stained to enhance its natural beauty. Cedar is more expensive than pine, but its durability and beauty make it a worthwhile investment.

When choosing wood for your project, it is also important to consider the trim. End grain is the exposed end of a piece of wood, and it is more porous than the rest of the wood. This means that it will absorb more moisture and be more prone to rotting. To prevent this, it is important to use trim that is either sealed or made from a more durable wood.

In summary, when choosing wood for your project, it is important to consider factors such as durability, availability, and appearance. Softwoods like pine are affordable and easy to work with, but may not hold up well in certain conditions. Cedar is a more expensive option, but its natural resistance to decay and insects make it a great choice for outdoor projects. It is also important to consider the trim and use materials that will prevent rotting.

Frequently Asked Questions

What size pocket hole screws are best for 2×4 to 2×4?

When joining 2×4 to 2×4 with a Kreg Jig, the best size of pocket hole screws to use is 2.5 inches. This size is perfect because it is long enough to pass through the 1.5-inch thickness of the 2×4 and still give enough grip to hold the joint firmly together.

What is the difference between Kreg Jig XL and HD?

The Kreg Jig XL and HD are both designed for heavy-duty projects, but they have some differences. The Kreg Jig XL is designed to work with 2x4s and larger stock, while the Kreg Jig HD is designed to work with 2x4s and larger stock that is 1-1/2 inches thick or more. The Kreg Jig HD also has a larger drill guide and a longer drill bit, making it ideal for larger projects.

How to use Kreg Jig K4 on 2×4?

To use a Kreg Jig K4 on a 2×4, first, set the drill bit collar to the correct depth. The collar should be set at 1-1/2 inches. Next, adjust the drill guide block to the correct thickness of the wood, which is 1-1/2 inches for a 2×4. Then, clamp the Kreg Jig K4 to the wood and drill the pocket hole with the drill bit. Finally, insert the pocket hole screw and tighten it with a screwdriver or drill.

Remember to always use the correct size pocket hole screws and to adjust the Kreg Jig settings to the correct thickness of the wood being used. With the right tools and techniques, joining 2x4s with a Kreg Jig can be a breeze.