Kreg Jig is a popular woodworking tool used to join two pieces of wood together. It is a pocket-hole jig that drills angled holes into a workpiece, allowing screws to be driven in at an angle to create a strong joint. However, one question that often arises is whether Kreg Jig requires special screws.

The answer is yes, Kreg Jig requires special screws. Kreg has specific screws that are designed to work with the specific driver that comes with the jig. These screws have a square driver hole that matches the driver, ensuring a secure and tight fit. The screws also come in different thread types, with course thread screws being used for soft woods and plywood, and fine thread screws being used for hardwoods.

Choosing the right screw for your project is important, as using the wrong screw can result in a weak joint or even damage to your workpiece. While it is possible to use regular screws with Kreg Jig, it is not recommended, as they may not fit properly and can result in a weaker joint. In the following sections, we will dive deeper into the types of screws used in Kreg Jig and how to choose the right screw for your project.

Key Takeaways

- Kreg Jig requires special screws that are designed to work with the specific driver that comes with the jig.

- Using the wrong screw can result in a weak joint or even damage to your workpiece.

- Choosing the right screw for your project is important to ensure a secure and tight fit.

Understanding Kreg Jig

Kreg Jig is a popular tool for woodworking enthusiasts and DIYers. It is a pocket hole jig that helps create strong and durable joints by drilling angled holes into one board and joining it to another using screws. The Kreg Jig is designed to work with a specific type of screw, which is different from regular wood screws.

The Kreg screws have a square driver hole that works with the driver that comes with the jig. They also come in two types – course thread and fine thread. The course thread screws are designed for use with softwoods and plywood, while the fine thread screws are for use with hardwoods.

Using the wrong type of screw can result in a weak joint that may not hold up over time. Therefore, it is important to use the right type of screw when using a Kreg Jig.

One of the benefits of using a Kreg Jig is that it allows for easy and fast joinery. It eliminates the need for clamps and glue, and the joints are strong and durable. The Kreg Jig is also versatile and can be used on a variety of boards, including 2x4s.

In summary, the Kreg Jig is a useful tool for woodworking and DIY projects that require strong and durable joints. It requires the use of specific screws that are designed to work with the jig, and using the wrong type of screw can result in a weak joint. The Kreg Jig is easy to use and versatile, making it a popular choice among woodworking enthusiasts.

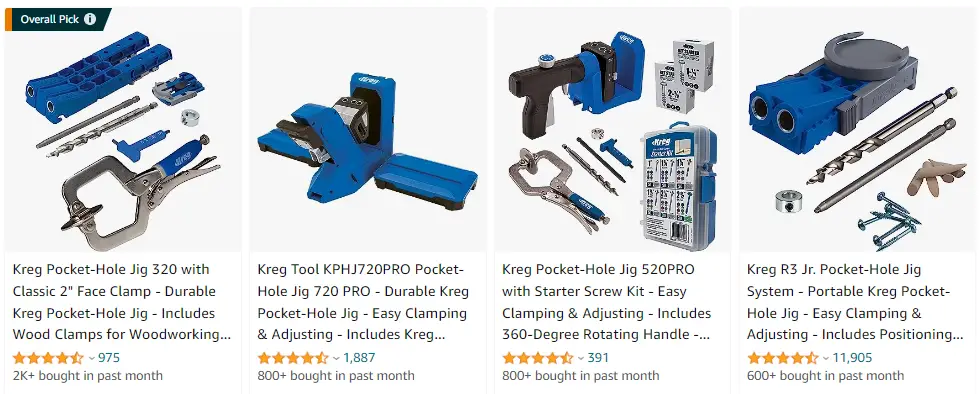

Kreg Pocket Hole Jigs

Click Here To Check The Prices On Amazon

Kreg Jig and Special Screws

When using a Kreg jig, it is important to use the correct type of screws to ensure a strong and secure joint. While it is not necessary to use Kreg screws specifically, it is recommended to use pocket-hole screws that are compatible with the Kreg jig system.

Kreg screws are designed with a square driver hole that works with the specific driver that comes with the Kreg jig. They come in both coarse and fine thread varieties, with coarse thread screws recommended for soft woods and plywood, and fine thread screws recommended for hardwoods.

When selecting the correct pocket-hole screw to use with a Kreg jig, it is important to consider the thickness of the material being used and where the project will be placed (indoors or outdoors). Kreg Tool provides a helpful guide on how to choose the correct screw for your project based on these factors.

While Kreg screws may be more expensive than other types of screws, there are alternatives available. However, it is important to ensure that any alternative screws used are compatible with the Kreg jig and provide a strong and secure joint.

In summary, while it is not necessary to use Kreg screws specifically, it is recommended to use pocket-hole screws that are compatible with the Kreg jig system to ensure a strong and secure joint. When selecting screws, consider the thickness of the material being used and where the project will be placed.

Types of Screws Used in Kreg Jig

When it comes to using a Kreg Jig, it is important to use the right type of screw for the job. The Kreg Jig system is designed to work with Kreg pocket-hole screws, which come in a variety of types and sizes. In this section, we will discuss the different types of screws that are commonly used with the Kreg Jig.

Coarse-Thread Screws

Coarse-thread screws are designed for use with softwoods and plywood. These screws have a larger thread pattern, which helps to pull the screw into the wood and create a strong joint. Coarse-thread screws are available in a variety of lengths and diameters, and are typically used for general woodworking projects.

Fine-Thread Screws

Fine-thread screws are designed for use with hardwoods. These screws have a smaller thread pattern, which helps to prevent the wood from splitting. Fine-thread screws are available in a variety of lengths and diameters, and are typically used for furniture and cabinetry projects.

Maxi-Loc Screws

Maxi-Loc screws are designed with a larger head that provides more holding power. These screws are available in both coarse and fine-thread varieties, and are typically used for larger projects where extra holding power is needed.

Pan-Head Screws

Pan-head screws are designed with a flat, rounded head that sits flush with the surface of the wood. These screws are available in both coarse and fine-thread varieties, and are typically used for projects where a low-profile screw head is desired.

Kreg pocket-hole screws are available in a variety of materials, including steel, zinc-coated, blue-kote™, and stainless steel. Each material has its own unique properties, such as corrosion resistance or strength, and should be chosen based on the specific needs of the project.

In addition to the standard screw types, Kreg also offers a variety of specialty screws, such as washer-head, bugle head, and self-tapping screws. These screws are designed for specific applications and should be chosen based on the needs of the project.

Overall, when using a Kreg Jig, it is important to choose the right type of screw for the job. By selecting the appropriate screw type and size, you can ensure a strong, durable joint that will last for years to come.

Choosing the Right Screw for Your Project

When working with a Kreg Jig, it is important to choose the right screw for your project to ensure a strong and secure joint. Fortunately, Kreg Tool provides a Screw Selector tool on their website to help you choose the right screw for your specific project.

One important factor to consider when selecting a screw is the material thickness you will be working with. Kreg screws come in a variety of lengths to accommodate different material thicknesses, ranging from 1/2 inch to 2-1/2 inches. It is important to choose a screw that is long enough to penetrate both pieces of material being joined without protruding out the other side.

Another factor to consider is the type of material you will be working with. Kreg screws are designed to work with a variety of materials, including hardwoods, softwoods, plywood, and composites. When working with hardwoods, it is important to choose a screw with a thicker shank to prevent splitting. For softwoods, a fine-thread screw is recommended to ensure a strong grip.

In addition to material type, the thickness of the material being joined also plays a role in screw selection. For thinner materials, a shorter screw length is recommended to prevent the screw from protruding out the other side. For thicker materials, a longer screw length is recommended to ensure a strong joint.

It is important to note that not all screws are created equal. Kreg screws are specifically designed to work with Kreg Jigs and are optimized for their unique design. While other screws may work, they may not provide the same level of strength and security as Kreg screws.

In summary, when selecting a screw for your Kreg Jig project, consider the material type, material thickness, and screw length. Use the Screw Selector tool on the Kreg Tool website to ensure you choose the right screw for your specific project. Always use Kreg screws for optimal strength and security.

Indoor Vs Outdoor Applications

When it comes to choosing the right screws for your Kreg Jig, it is important to consider the application of your project. Whether you are building something for indoor or outdoor use will determine the type of screws you should use.

For indoor projects, you can use regular Kreg screws. These screws are made of hardened steel and are designed to hold up well in indoor environments. They are not coated, so they are not suitable for outdoor use.

On the other hand, if you are building something for outdoor use, you will need to use Kreg screws that are specially designed for outdoor applications. These screws are coated with a special material that makes them resistant to rust and corrosion. They are also designed to hold up well in extreme weather conditions.

When selecting screws for outdoor use, it is important to consider the type of wood you are using. Pressure-treated wood requires a special type of screw that is designed to hold up well in this type of wood. Kreg has a range of screws that are designed specifically for use with pressure-treated wood.

In general, it is always a good idea to choose screws that are specifically designed for the type of project you are working on. This will ensure that your project is strong, durable, and long-lasting.

Overall, when using a Kreg Jig, it is important to choose the right screws for your project. By considering whether your project is for indoor or outdoor use, and the type of wood you are using, you can ensure that you select the right screws for your project.

Alternative Screw Options

While Kreg Jig pocket hole screws are specifically designed to work with the Kreg Jig, there are alternative screw options available that can be used with the jig.

One of the most popular alternative screw options is regular wood screws. These screws can be used in place of Kreg screws, but they require pre-drilling. Regular wood screws come in a variety of sizes and lengths, making them a versatile option for different types of projects.

Another alternative screw option is drywall screws. These screws are self-tapping and do not require pre-drilling, making them a convenient option for quick projects. However, drywall screws are not as strong as Kreg screws or wood screws, so they may not be suitable for heavy-duty applications.

Home Depot carries a range of alternative screw options that can be used with the Kreg Jig, including wood screws and drywall screws. These screws are available in various sizes and lengths, making it easy to find the right screw for your project.

It’s important to note that while alternative screws can be used with the Kreg Jig, they may not provide the same level of strength and durability as Kreg screws. It’s always a good idea to test alternative screws on a scrap piece of wood before using them on your project to ensure they will work as expected.

In summary, while Kreg Jig pocket hole screws are the recommended screw option for use with the Kreg Jig, there are alternative screw options available. Regular wood screws and drywall screws are two popular options that can be used in place of Kreg screws. Home Depot carries a range of alternative screw options that can be used with the Kreg Jig. However, it’s important to test alternative screws before using them on your project to ensure they will work as expected.

Frequently Asked Questions

Can I use regular deck screws with Kreg Jig?

No, it is not recommended to use regular deck screws with Kreg Jig. Kreg Jig requires special screws that have a square driver hole that works with the specific driver that comes with the jig. The wide bearing surface of the Kreg screws will not overdrive in the bottom of the pocket, which is especially important in softer materials such as plywood and composites. Regular deck screws may not have the same bearing surface and can cause splitting or other issues.

Where can I find Kreg screws near me?

Kreg screws can be found at many hardware stores, home improvement stores, and online retailers. Some popular stores that carry Kreg screws include Home Depot, Lowe’s, and Amazon. It’s important to ensure that you purchase the correct screws for your project, as Kreg screws come in course and fine thread. Course thread screws are for soft woods and plywood, while fine thread is for hard woods.

What length of pocket hole screws should I use for 2×4?

The length of pocket hole screws you should use for 2x4s depends on the thickness of the material you are joining. For a standard 2×4, which is 1.5 inches thick, Kreg recommends using 2.5-inch pocket hole screws. It’s important to use the correct length of screw to ensure a strong and secure joint. If you are joining thicker or thinner material, you may need to adjust the length of the screw accordingly.