Kreg screws are widely used in woodworking projects to join pieces of wood together. However, one question that often arises is how much weight can a Kreg screw hold? The answer to this question depends on several factors, including the type of Kreg screw used, the thickness and type of material being joined, and the application technique.

Understanding Kreg screws and their weight capacity is crucial for ensuring the strength and stability of woodworking projects. Kreg screws are specially designed for pocket-hole joinery, which involves drilling angled holes into one piece of wood and then joining it to another piece using a screw. While Kreg screws are known for their strength and durability, their weight capacity can vary depending on several factors.

Table of Contents

Key Takeaways

- The weight capacity of Kreg screws depends on several factors, including screw type, material thickness, and application technique.

- Choosing the right screw length and thickness is crucial for ensuring the strength and stability of woodworking projects.

- Kreg screws are specially designed for pocket-hole joinery, which involves drilling angled holes into one piece of wood and then joining it to another piece using a screw.

Understanding Kreg Screws

Kreg screws are specialized self-tapping wood screws designed for use with pocket-hole joinery. They are available in various lengths, thread types, and diameters to accommodate different wood thicknesses and applications.

Kreg screws are available in two thread types: coarse and fine. Coarse-thread screws are suitable for softwoods and MDF, while fine-thread screws are better for hardwoods and plywood. Coarse-thread screws have a larger pitch and are more aggressive, making them ideal for fastening into soft materials. Fine-thread screws have a smaller pitch and are less aggressive, making them better for hardwoods and other dense materials.

Kreg screws are also available in different lengths, ranging from 1 inch to 2 1/2 inches. The length of the screw should be selected based on the thickness of the wood being joined. Kreg offers a screw selector tool to help users choose the correct screw length based on the thickness of the material.

The diameter of the screw is also an important consideration. Kreg screws are available in two diameters: 7/16 inch and 1/2 inch. The 7/16 inch diameter screws are designed for use with material up to 1 inch thick, while the 1/2 inch diameter screws are designed for use with material up to 1 1/2 inches thick.

In general, Kreg screws are stronger than traditional wood screws. This is because they have a larger diameter and a coarse thread that provides better holding power. According to a study conducted by the RADCO testing division, a common 90-degree pocket hole joint using a 2×4 rail that is attached to a 4×4 post could hold 1361 lbs before failing.

In conclusion, Kreg screws are an excellent choice for pocket-hole joinery. They are available in various lengths, thread types, and diameters to accommodate different wood thicknesses and applications. Kreg screws are also stronger than traditional wood screws, making them ideal for heavy-duty applications.

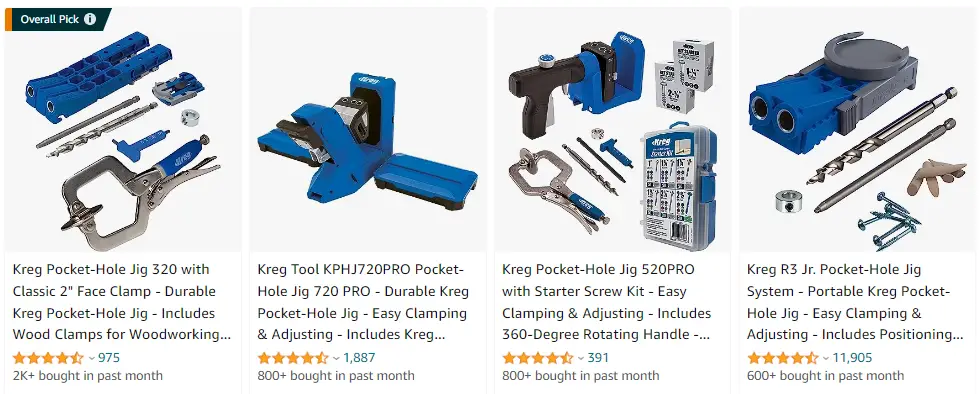

Kreg Pocket Hole Jigs

Click Here To Check The Prices On Amazon

The Role of Material in Weight Capacity

The material used for the project plays a crucial role in determining the weight capacity of a Kreg screw. Different materials have different densities and strengths, which can affect the screw’s holding power.

For instance, plywood is a common material used in woodworking projects. Its layers of thin wood veneers glued together make it stronger than solid wood of the same thickness. However, the type of plywood used can also affect the screw’s holding power. Some types of plywood have a softer core, making them less dense and weaker than others.

The thickness of the material also affects the screw’s holding power. Thicker materials can generally support more weight than thinner ones. However, thicker materials may require longer screws to ensure a secure hold.

When using Kreg screws, it is important to choose the appropriate screw size and material for the project to ensure optimal holding power. The Kreg Screw Selector Wheel can help determine the appropriate screw size for the material being used.

In summary, the material used and its thickness are important factors in determining the weight capacity of a Kreg screw. It is essential to choose the appropriate screw size and material for the project to ensure a secure hold.

Kreg Screw Strength and Weight Capacity

Kreg screws are designed to provide strong and long-lasting joints in woodworking projects. The strength and weight capacity of Kreg screws depend on various factors such as the type of screw, the material being joined, and the thickness of the material.

According to a study conducted by the RADCO testing division, a common 90-degree pocket hole joint using a 2×4 rail that is attached to a 4×4 post could hold 1361 lbs before failing. However, using the same setup, if you apply pressure from the bottom of 2×4, the same side as the holes, this 2×4 holds only 410 lbs. This suggests that the direction of force is an important factor in determining the strength of the joint.

Kreg offers a complete line of pocket screws for every workpiece thickness and type. All Kreg pocket screws are available at your Kreg dealer or online at kregtool.com. The Kreg Screw Selector Tool helps you choose the right screw for your project based on the material type and thickness.

The withdrawal force of a screw refers to the amount of force required to pull the screw out of the material. The withdrawal force of Kreg screws is generally strong, but it can vary depending on the material being joined. For example, the withdrawal force of a Kreg screw in softwood is generally higher than in hardwood.

The tensile strength of a screw refers to the amount of force required to break the screw. Kreg screws are made of high-quality steel and have a high tensile strength, which makes them durable and long-lasting.

In summary, the strength and weight capacity of Kreg screws depend on various factors such as the type of screw, the material being joined, and the thickness of the material. Kreg offers a complete line of pocket screws for every workpiece thickness and type, and the Kreg Screw Selector Tool helps you choose the right screw for your project based on the material type and thickness. The withdrawal force and tensile strength of Kreg screws are generally strong, but they can vary depending on the material being joined.

The Importance of Screw Length and Thickness

When it comes to determining the weight capacity of Kreg screws, the length and thickness of the screw are two critical factors to consider. The thickness of the material being joined will determine the screw length required to achieve a secure and strong joint.

Kreg screws come in various lengths, ranging from 1 inch to 2.5 inches, with each length suited for different thicknesses of materials. The screw length selection guide provided by Kreg can help determine the appropriate screw length for a specific project. The guide recommends that the screw length should be at least 1/2 inch shorter than the combined thickness of the materials being joined. For example, if the combined thickness of the material is 1 inch, a 1/2-inch screw should be used.

It is important to note that using the correct screw length is crucial for ensuring the strength and stability of the joint. Using a screw that is too short may not provide enough holding power, while a screw that is too long may cause the wood to split.

In addition to screw length, the thickness of the material being joined is also a critical factor to consider. Kreg screws are designed to work with materials of various thicknesses, ranging from 1/2 inch to 1-1/2 inches. Using a screw that is too short for the thickness of the material may not provide enough holding power, while using a screw that is too long may cause the screw to protrude through the other side of the material.

To ensure the best results, it is essential to use the appropriate screw length and thickness for the materials being joined. By doing so, you can achieve a strong and stable joint that can support the weight of the project.

Types of Projects and Their Requirements

When it comes to choosing the right Kreg screw for a project, several factors come into play. The thickness of the material being used, the type of wood, and the project’s location, whether indoor or outdoor, are all important considerations. Here are some common DIY projects and their screw requirements:

Indoor Projects

For indoor projects such as cabinets, bookshelves, or furniture, Kreg recommends using their Zinc Pocket-Hole Screws. These screws are available in different lengths, ranging from 1 inch to 2.5 inches, to accommodate various material thicknesses. Zinc screws are also resistant to corrosion, ensuring that the project remains secure and stable over time.

Outdoor Projects

For outdoor projects such as decking, garden benches, or picnic tables, Kreg recommends using their Blue-Kote Pocket-Hole Screws. These screws are coated with a rust-resistant material, which makes them suitable for outdoor use. Blue-Kote screws are available in different lengths, ranging from 1.25 inches to 2.5 inches, to accommodate various material thicknesses.

Construction Projects

For construction projects such as framing or building walls, Kreg recommends using their Maxi-Loc Pocket-Hole Screws. These screws are designed to provide maximum holding power and are available in lengths ranging from 1.25 inches to 2.5 inches. Maxi-Loc screws are also coated with a rust-resistant material, making them suitable for outdoor use.

In summary, choosing the right Kreg screw for a project is essential to ensure its stability and longevity. By considering the project’s location, material thickness, and type of wood, you can select the appropriate screw for the job.

Using Kreg Jig for Pocket-Hole Joinery

Kreg Jig is a popular tool used for creating pocket holes in woodworking projects. Pocket-hole joinery is a technique that involves drilling angled holes into a workpiece and then joining it to another workpiece with a pocket screw. This technique is widely used in the woodworking industry due to its strength, speed, and ease of use.

When using Kreg Jig for pocket-hole joinery, it is important to choose the right size of pocket screws. The size of the pocket screw depends on the thickness of the workpiece being joined. Kreg Jig comes with a chart that shows the recommended screw size for different thicknesses of wood.

Another important factor to consider when using Kreg Jig is the angle of the pocket hole. The angle of the pocket hole determines the strength of the joint. Kreg Jig comes with a built-in drill guide that ensures that the pocket hole is drilled at the correct angle.

One of the advantages of using Kreg Jig for pocket-hole joinery is that it allows for strong, hidden joints. The pocket screw is driven into the pocket hole and then into the second workpiece, creating a strong, secure joint that is hidden from view. This makes it ideal for projects where the appearance of the joint is important.

In terms of weight capacity, pocket-hole joints made with Kreg Jig and pocket screws are quite strong. According to a study conducted by the RADCO testing division, a common 90-degree pocket-hole joint using a 2×4 rail that is attached to a 4×4 post could hold 1361 lbs before failing. However, using the same setup, if you apply pressure from the bottom of 2×4, the same side as the holes, this 2×4 holds only 410 lbs.

Overall, using Kreg Jig for pocket-hole joinery is a great way to create strong, hidden joints in woodworking projects. By following the recommended screw size and drilling angle, you can ensure that your joints are strong and secure.

Drilling and Application Techniques

To achieve the maximum strength and durability of a Kreg joint, it is important to follow the proper drilling and application techniques. Here are some tips to keep in mind:

Drill Bit

The Kreg Jig® R3 comes with a 3/8″ step drill bit that is designed to create the perfect pocket hole. It is important to use this drill bit to ensure that the screw fits snugly into the pocket hole. Using a different size drill bit may result in a loose fit, which can weaken the joint.

Stepped Drill Bit

For thicker materials, the Kreg Jig® HD (Heavy-Duty) is recommended. This jig requires a 1/2″ stepped drill bit, which is included with the jig. The stepped design of the drill bit allows for the screw to be driven at the proper angle and depth, resulting in a strong joint.

Application

When applying the screw, it is important to use the correct length and type of screw for the material being joined. Kreg offers a variety of screw lengths and types to accommodate different thicknesses and applications. It is important to choose the right screw to ensure that the joint is strong and secure.

Pilot Hole

In some cases, it may be necessary to create a pilot hole before driving the screw. This is especially true when joining hardwoods or when using screws that are longer than 1-1/2″. A pilot hole helps to prevent the wood from splitting and ensures that the screw goes in straight.

By following these drilling and application techniques, you can create strong and durable joints with Kreg screws.

Understanding Joint Strength in Woodworking

In woodworking, joint strength is a critical factor to consider when building furniture or other wooden structures. The joint is the area where two pieces of wood come together, and the strength of the joint determines how much weight it can bear. There are several types of joints used in woodworking, including dovetails, biscuits, and pocket screws.

Dovetails are one of the strongest types of joints used in woodworking. They are created by cutting interlocking “teeth” into the wood, which creates a very strong connection. However, dovetails can be difficult to create, and they require a lot of skill and practice to get right.

Biscuits are another type of joint that is commonly used in woodworking. They are created by cutting a slot into the wood and inserting a thin, oval-shaped piece of wood known as a biscuit. The biscuit expands when it comes into contact with glue, creating a strong bond between the two pieces of wood.

Clamps are also an important tool for creating strong joints in woodworking. They are used to hold the pieces of wood together while the glue dries. Without clamps, the joint may not be strong enough to bear weight.

When it comes to pocket screws, the strength of the joint depends on the size of the screw and the type of wood being used. According to a study conducted by the RADCO testing division, a common 90-degree pocket hole joint using a 2×4 rail that is attached to a 4×4 post could hold 1361 lbs before failing. However, using the same setup, if you apply pressure from the bottom of 2×4, the same side as the holes, this 2×4 holds only 410 lbs.

In conclusion, joint strength is a crucial factor to consider in woodworking. The type of joint used, the quality of the wood, and the tools and techniques used to create the joint all play a role in determining how much weight the joint can bear. While there are many different types of joints to choose from, each with its own strengths and weaknesses, it is important to choose the right joint for the job to ensure a strong and durable connection.

Additional Products and Items

In addition to Kreg screws, there are other products and items that can be used to enhance the strength of pocket hole joints.

Wood Glue

One such item is wood glue. Applying wood glue to the joint before screwing the pieces together can significantly increase the joint’s strength. The glue fills any gaps in the joint and creates a bond that can withstand a great deal of stress. It is important to note that the glue should be allowed to dry completely before any weight is placed on the joint.

Pocket Hole Plugs

Another product that can be used with pocket hole joints is pocket hole plugs. These are small wooden plugs that can be inserted into the pocket hole after the screw has been inserted. They provide a clean, finished look to the joint and can also add to the joint’s strength by filling any gaps in the hole. Pocket hole plugs are available in a variety of wood species and can be sanded and finished to match the surrounding wood.

Clamp

A clamp can also be a helpful tool when working with pocket hole joints. It can be used to hold the pieces in place while the screw is inserted, ensuring that the joint is tight and secure. A clamp can also be used to hold the joint together while the wood glue dries.

Includes

Some Kreg screw sets come with additional items such as a drill bit, driver bit, and depth collar. These items are designed to work together to create a pocket hole joint that is strong and secure. The drill bit creates the pocket hole, the driver bit inserts the screw, and the depth collar ensures that the screw is inserted to the correct depth.

Overall, using these additional products and items can help to create pocket hole joints that are strong and secure. By using wood glue, pocket hole plugs, clamps, and other items in conjunction with Kreg screws, woodworkers can create joints that can withstand a great deal of stress and weight.

Assessing Lateral Force

When assessing the weight a Kreg screw can hold, it is important to consider the lateral force that may be applied to the joint. Lateral force is any force that is perpendicular to the direction of the screw, such as the force that may be applied when a joint is twisted or bumped.

According to a study conducted by the RADCO testing division, a common 90-degree pocket hole joint using a 2×4 rail that is attached to a 4×4 post could hold 1361 lbs before failing. However, if pressure is applied from the bottom of the 2×4, on the same side as the holes, the 2×4 can hold only 410 lbs. This highlights the importance of considering lateral force when assessing the weight a Kreg screw can hold.

It is also important to note that the weight a screw can hold is influenced by various factors, such as the length of the screw, the type of thread, the quality of the screw, the way it was inserted, and the type of forces that will be acting on it. In general, a screw can hold 80-100 pounds, but this number can vary depending on these factors.

When using Kreg screws, it is recommended to use the correct screw length for the workpiece thickness and type. Kreg offers a complete line of pocket screws for every workpiece thickness and type, and all Kreg pocket screws are available at your Kreg dealer or online at www.kregtool.com.

Overall, when assessing the weight a Kreg screw can hold, it is important to consider the lateral force that may be applied to the joint, as well as the various factors that can influence the weight the screw can hold. By using the correct screw length and type, and considering the forces that may be acting on the joint, you can ensure a strong and secure joint that will stand up to the test of time.

Frequently Asked Questions

What is the weight limit for Kreg screws?

According to Power Tool Base, a screw can hold 80-100 pounds (36-45kg) in weight as a general rule. However, the weight limit for Kreg screws can vary depending on the length, thread type, quality, and condition of the screw, as well as the forces placed on it. It is important to choose the correct type and length of screw for your project.

How do I choose the right Kreg screw for my project?

Kreg offers a complete line of pocket screws for every workpiece thickness and type. The screw length is measured from the bottom of the head to the tip of the screw. Use the chart provided in the Kreg Owner’s Manual to select the correct screw length. When choosing a screw, consider the thickness of the workpiece and the type of wood being used. Kreg pocket screws are available at your Kreg dealer or online at www.kregtool.com.

What is the advantage of using pocket hole screws over dowels?

Pocket hole screws provide a strong and secure joint that is easy to assemble. Unlike dowels, pocket hole screws do not require a lot of precision and can be used with a variety of materials. Additionally, pocket hole screws do not require glue, which can make disassembly easier if necessary. Overall, pocket hole screws are a versatile and reliable option for assembling furniture and other woodworking projects.