When it comes to woodworking, the Kreg Jig is a popular tool for creating pocket holes to join two pieces of wood together. The Kreg Jig comes with its own specially designed screws that are meant to be used with the tool. However, many woodworkers wonder if regular deck screws can be used with the Kreg Jig instead.

The answer to this question is yes, regular deck screws can be used with the Kreg Jig. However, it is important to note that the Kreg Jig is designed to work with its own screws, which are self-tapping and have a flat-bottomed head that sits flush in the pocket hole. Using regular deck screws may not provide the same level of security and tight fit that the Kreg screws do.

Key Takeaways

- While regular deck screws can be used with the Kreg Jig, it is recommended to use the Kreg screws for the best results.

- Kreg screws are designed to work with the self-tapping holes created by the Kreg Jig and provide a secure and tight fit.

- Using regular deck screws may not provide the same level of security and tight fit as the Kreg screws.

Understanding Kreg Jig

Kreg Jig is a popular tool used in woodworking and DIY projects to create strong, hidden joints. It works by using a drill guide and stop collar to create pocket holes in wood, which are then joined together using special screws designed for the Kreg Jig system.

The pocket-hole jig is an essential component of the Kreg Jig system. It allows users to drill angled holes into the edge or face of a piece of wood, creating a pocket that can be used to attach another piece of wood at a right angle. The drill guide ensures that the hole is drilled at the correct angle, while the stop collar ensures that the hole is drilled to the correct depth.

One of the key benefits of using Kreg Jig is that it creates a strong joint that is hidden from view. This is because the screws are driven into the pocket hole at an angle, which pulls the two pieces of wood tightly together. This creates a strong, secure joint that is much stronger than a butt joint or other types of joints.

While it is possible to use regular screws with Kreg Jig, it is not recommended. Regular screws may not fit properly into the pocket hole, which can result in a weaker joint. In addition, regular screws may not be long enough to reach the second piece of wood, which can also weaken the joint.

To ensure the best results when using Kreg Jig, it is important to use the correct screws. Kreg Jig screws are specially designed for use with the Kreg Jig system and come in a range of sizes and styles to suit different types of wood and projects. It is important to choose the correct screw for your project to ensure a strong, secure joint.

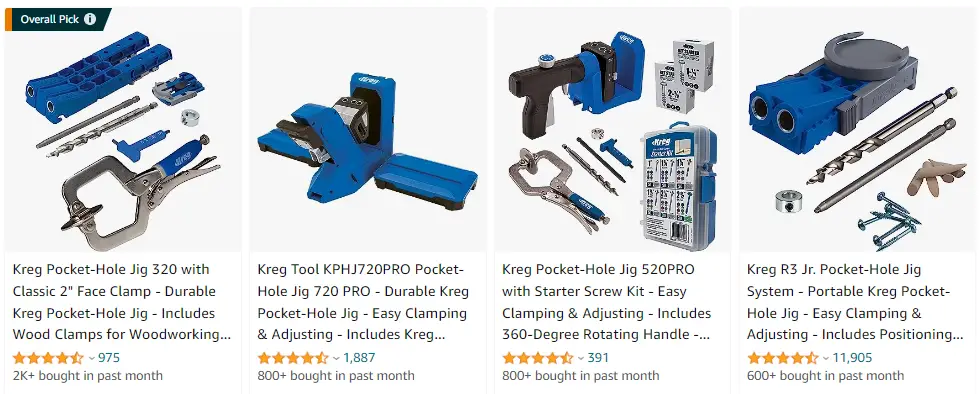

Kreg Pocket Hole Jigs

Click Here To Check The Prices On Amazon

Types of Screws

When it comes to using a Kreg Jig, there are several types of screws that can be used. The Kreg Jig is designed to work with Kreg pocket holes, which use a special self-tapping, hardened-steel screw. However, it is possible to use other types of screws with a Kreg Jig as well.

Deck Screws

Deck screws are a popular type of screw that can be used with a Kreg Jig. These screws are designed for outdoor use and are coated with a special material that helps prevent rust and corrosion. Kreg offers Protec-Kote™ Deck Screws which are coated with a three-layer coating for long-lasting performance outdoors.

Wood Screws

Wood screws are another option for use with a Kreg Jig. These screws are designed specifically for use with wood and come in a variety of sizes and lengths. They can be used for a wide range of applications, including furniture building, cabinet making, and more.

Drywall Screws

While not typically recommended for use with a Kreg Jig, drywall screws can be used in a pinch. These screws are designed for use with drywall and are not as strong as other types of screws. However, they can work well for lighter applications.

Pocket Hole Screws

Pocket hole screws are the recommended screw for use with a Kreg Jig. These screws are designed specifically for use with pocket holes and are available in a variety of sizes and lengths. Kreg offers a range of pocket hole screws, including coarse-thread screws, fine-thread screws, maxi-loc screws, and more.

Alternative Screws

While Kreg pocket hole screws are the recommended option, there are alternative screws that can be used with a Kreg Jig. For example, some people have had success using stainless steel screws or pan-head screws. However, it is important to note that not all screws will work with a Kreg Jig and it is important to select screws that are appropriate for the job.

Screw Selection

When selecting screws for use with a Kreg Jig, it is important to consider the material being used and the specific application. Coarse-thread screws are typically used for softwoods, while fine-thread screws are better suited for hardwoods. Washer head, bugle head, and flat head screws are all options depending on the specific needs of the project.

In conclusion, there are several types of screws that can be used with a Kreg Jig, including deck screws, wood screws, drywall screws, pocket hole screws, and alternative screws. When selecting screws, it is important to consider the material being used and the specific application to ensure the best results.

Understanding Material Types

When using a Kreg Jig, it is important to consider the type of material being used. Different materials will require different types of screws to ensure a secure and tight joint. Here is a breakdown of the most common types of materials used in woodworking and the recommended screw types for each:

Softwood

Softwoods, such as pine and spruce, are commonly used in woodworking projects. When working with softwoods, it is recommended to use coarse-threaded wood screws, such as the Kreg SML-C125-250 1-1/4-Inch Coarse Thread Pocket Hole Screws. These screws are designed to provide maximum grip and holding power in softwoods.

Hardwood

Hardwoods, such as oak and maple, are denser and harder than softwoods. When working with hardwoods, it is recommended to use fine-threaded wood screws, such as the Kreg SML-F125-250 1-1/4-Inch Fine Thread Pocket Hole Screws. These screws are designed to prevent splitting and provide a tight, secure joint in hardwoods.

Plywood

Plywood is a versatile material that is commonly used in woodworking projects. When working with plywood, it is recommended to use coarse-threaded wood screws, such as the Kreg SML-C125-250 1-1/4-Inch Coarse Thread Pocket Hole Screws. These screws are designed to provide maximum grip and holding power in plywood.

Cedar and Pressure-Treated Wood

Cedar and pressure-treated wood are commonly used in outdoor woodworking projects. When working with cedar or pressure-treated wood, it is recommended to use stainless steel screws, such as the Kreg SML-C250B-250 2-1/2-Inch Blue-Kote Pocket Hole Screws. These screws are designed to resist corrosion and provide a long-lasting, secure joint in outdoor projects.

By selecting the appropriate screw for the type of material being used, woodworkers can ensure a strong and secure joint when using a Kreg Jig.

Project Types and Suitable Screws

When it comes to using a Kreg Jig for joining boards together, it is important to choose the right screws for the job. The type of project will determine the type of screw that should be used.

For outdoor applications, such as building a deck, it is recommended to use stainless steel screws. These screws are resistant to rust and corrosion, making them ideal for outdoor use. Deck screws are specifically designed for use with deck boards and joists, and they come in a variety of lengths and thicknesses.

For indoor projects, such as furniture building, regular wood screws can be used with a Kreg Jig. These screws are readily available at most hardware stores and come in a variety of sizes and lengths. It is important to choose a screw that is long enough to go through both pieces of wood being joined together.

When using a Kreg Jig, it is important to choose the right thread type for the screw. Coarse thread screws are recommended for soft woods and plywood, while fine thread screws are recommended for hard woods. This is because coarse thread screws have a more aggressive thread pattern that bites into the softer wood, while fine thread screws have a smoother thread pattern that is less likely to split hard woods.

In summary, when using a Kreg Jig, it is important to choose the right screw for the job. For outdoor applications, stainless steel deck screws are recommended, while regular wood screws can be used for indoor projects. It is also important to choose the right thread type for the screw based on the type of wood being used.

Creating Pocket Holes with Kreg Jig

Kreg Jig is a pocket-hole jig that enables users to drill angled holes into a workpiece, allowing screws to be driven in at an angle to create a strong joint. Pocket-hole joinery is a popular method of joining wood because it is quick, easy, and provides a strong, tight joint.

To create pocket holes with Kreg Jig, the user needs to follow a few simple steps. First, they need to select the appropriate drill bit for the thickness of the workpiece. The Kreg Jig comes with a drill guide that helps users drill the pocket holes at the correct angle.

Next, the user needs to set the depth of the drill bit using a stop collar. The stop collar ensures that the drill bit does not drill too deep into the workpiece, creating a pilot hole that is too large for the screw.

Once the drill bit is set to the correct depth, the user can clamp the workpiece into the Kreg Jig and drill the pocket hole. The drill bit will create a pilot hole and an angled pocket hole in the workpiece.

It is important to note that Kreg Jig requires special screws for pocket-hole joinery. The Kreg screws have a square driver hole that works with the specific driver that comes with the jig. The screws come in coarse and fine thread. Coarse thread screws are for soft woods and plywood, while fine thread screws are for hardwoods.

In conclusion, creating pocket holes with Kreg Jig is a simple and effective way to join wood. By following the steps outlined above, users can create strong, tight joints that will last for years to come. It is important to use the correct drill bit, set the depth correctly, and use the appropriate Kreg screws for the best results.

Considerations for Screw Length and Thickness

When using regular deck screws with a Kreg Jig, it’s important to consider the length and thickness of the screws to ensure a secure joint. Here are some factors to keep in mind:

Screw Length

The length of the screw you use will depend on the thickness of the material you’re joining. As a general rule of thumb, the screw should be long enough to go through both pieces of material and penetrate at least 1 inch into the second piece.

For example, if you’re joining two pieces of 1/2-inch thick material, you’ll want to use a screw that’s at least 1 1/2 inches long. If you’re joining two pieces of 3/4-inch thick material, you’ll want to use a screw that’s at least 2 inches long.

Screw Thickness

The thickness of the screw you use is also important. If the screw is too thin, it may not be able to hold the joint together properly. If the screw is too thick, it may split the wood.

As a general rule of thumb, the screw should be thick enough to grab onto the two boards without splitting them. For most applications, an 8-10 gauge screw is considered standard. For deck screws, a 3-inch screw with a 1-inch unthreaded shank is recommended.

Inches

When measuring screw length and thickness, it’s important to use inches as the unit of measurement. This is because most screws are sold in inches, and using a different unit of measurement can lead to confusion and errors.

In summary, when using regular deck screws with a Kreg Jig, it’s important to consider the length and thickness of the screws to ensure a secure joint. The screw should be long enough to go through both pieces of material and penetrate at least 1 inch into the second piece, and thick enough to grab onto the two boards without splitting them. Using inches as the unit of measurement can help avoid confusion and errors.

Creating Long-Lasting Joints with Kreg Jig

When it comes to pocket-hole joinery, the Kreg Jig is a popular tool used by many woodworkers. It is designed to make joining boards together quick, easy, and secure. However, not all screws are created equal, and using the wrong type of screw can result in weak joints that won’t stand the test of time.

To create long-lasting joints with the Kreg Jig, it is essential to use the correct type of screw. Kreg Pocket-Hole Screws are specifically designed for use with the Kreg Jig and are made of hardened-steel that is self-tapping. This means that they are able to drill their own hole and create threads as they are screwed into the wood, resulting in a strong and secure joint.

When using the Kreg Jig, it is important to consider the direction of the wood fibers. Pocket-hole joinery works by drilling angled holes into the wood, which can cause the wood fibers to split if not done correctly. To avoid this, it is recommended to drill the pocket holes in the direction of the wood grain. This will help to prevent the wood fibers from splitting and ensure a strong joint.

Another important factor to consider when creating long-lasting joints with the Kreg Jig is the use of glue. While it is not necessary to use glue with pocket-hole joinery, it can help to strengthen the joint and prevent it from loosening over time. When using glue, it is important to apply it to both surfaces being joined and clamp them together until the glue has dried.

In summary, to create long-lasting joints with the Kreg Jig, it is important to use Kreg Pocket-Hole Screws, drill the pocket holes in the direction of the wood grain, and consider using glue to strengthen the joint. By following these guidelines, woodworkers can ensure that their joints are strong and secure, and will stand the test of time.

Understanding Kreg Deck Jig

Kreg Deck Jig is a tool designed to make it easy to create perfectly placed and angled pocket holes in deck boards for a strong and secure deck. It is used in combination with Kreg Deck Screws to create a strong bond between the deck boards and the underlying structure.

The Kreg Deck Jig is designed to work with a variety of deck board thicknesses. It features three drill guides that are adjustable to accommodate boards that are 1-1/4″, 1-1/2″, and 2-1/2″ thick. This makes it easy to create pocket holes in a wide range of deck boards.

When using the Kreg Deck Jig, it is important to use the correct Kreg Deck Screws. These screws are specially designed to work with the pocket holes created by the Kreg Deck Jig. They feature a self-tapping tip that makes it easy to drive them into the deck boards without the need for pre-drilling.

The Kreg Deck Screws are available in two different thread types: coarse and fine. Coarse thread screws are designed for use with softwoods and composite decking, while fine thread screws are designed for use with hardwoods.

The Kreg Deck Jig also features a depth collar that ensures that the screws are driven to the correct depth. This helps to prevent overdriving or underdriving the screws, which can weaken the joint.

Overall, the Kreg Deck Jig is a valuable tool for anyone looking to build a strong and secure deck. By using the correct Kreg Deck Screws and following the instructions carefully, it is easy to create perfectly placed and angled pocket holes in deck boards for a strong and long-lasting deck.

Screws for Different Wood Types

When it comes to using a Kreg Jig, it’s important to choose the right screws for the type of wood you’re using. Different wood types have different densities and strengths, which can affect the holding power of the screws.

Hardwood

For hardwoods, it’s important to use screws that are strong enough to penetrate the dense wood. Kreg’s HD (Heavy-Duty) screws are a good choice for hardwoods. These screws have a larger diameter and a stronger shank than standard screws, making them ideal for use in hardwoods like oak and maple.

Softwood

Softwoods like pine and spruce are less dense than hardwoods and require a different type of screw. Kreg’s standard screws are a good choice for softwoods. These screws have a fine thread that provides good holding power in softwoods without splitting the wood.

Plywood

Plywood is a composite wood product that is made by gluing together layers of wood veneer. Because plywood is made up of thin layers of wood, it’s important to use screws that won’t split the wood. Kreg’s fine-thread screws are a good choice for plywood.

Cedar

Cedar is a softwood that is known for its natural resistance to decay and insects. When using cedar, it’s important to use screws that won’t react with the natural oils in the wood. Kreg’s stainless steel screws are a good choice for cedar.

Pressure-Treated Wood

Pressure-treated wood is wood that has been treated with chemicals to make it resistant to decay and insects. When using pressure-treated wood, it’s important to use screws that are resistant to corrosion. Kreg’s Protec-Kote screws are a good choice for pressure-treated wood.

In summary, choosing the right screws for the type of wood you’re using is important for ensuring a strong and secure joint. Kreg offers a variety of screws that are designed to work with different wood types, so be sure to choose the right screws for your project.

Understanding Screw Heads

When it comes to Kreg Jig, the type of screw head you choose is important to ensure a secure and strong joint. There are several types of screw heads available, and each has its own unique characteristics that make it suitable for different applications.

Washer-Head Screws

Washer-head screws are a popular choice for use with Kreg Jig. They have a large, flat head that provides a wide bearing surface, which helps to prevent the screw from pulling through the workpiece. Additionally, the washer head can help to distribute the clamping force more evenly, which can result in a stronger joint.

Pan-Head Screws

Pan-head screws are another option for use with Kreg Jig. They have a slightly rounded head that is wider than the shank of the screw, which can help to prevent the screw from pulling through the workpiece. Pan-head screws are a good choice for use with softer woods, as they can help to prevent splitting.

Bugle-Head Screws

Bugle-head screws have a similar shape to pan-head screws, but with a more pronounced taper. This can make them a good choice for use with drywall and other materials that require a flush finish. However, bugle-head screws are not recommended for use with Kreg Jig, as their shape can make them more prone to stripping.

Flat-Head Screws

Flat-head screws have a countersunk head that is designed to sit flush with the surface of the workpiece. While flat-head screws can be used with Kreg Jig, they are not recommended, as their shape can make them more prone to stripping.

Upper Shank and Smooth Upper Shank

Another important consideration when choosing screws for Kreg Jig is the upper shank of the screw. The upper shank is the portion of the screw that extends beyond the threads and into the workpiece. Smooth upper shank screws are recommended for use with Kreg Jig, as they can help to prevent the screw from splitting the workpiece.

Overall, when selecting screws for use with Kreg Jig, it is important to choose a screw with a head that is appropriate for the application, and a smooth upper shank that will not split the workpiece.

Tips for Woodworkers Using Kreg Jig

When using the Kreg Jig, it is important to use the right screws. While it may be tempting to use regular deck screws, it is not recommended. The Kreg screws are specifically designed to work with the Kreg Jig, ensuring a strong and secure joint.

Here are some tips for woodworkers using the Kreg Jig:

Use the Right Screws

As mentioned earlier, it is important to use the right screws when using the Kreg Jig. The Kreg screws have a square driver hole that works with the specific driver that comes with your jig. The screws come in course and fine thread. Course thread screws are for soft woods and plywood, and fine thread is for hard woods.

Pre-Drill Pilot Holes

When using the Kreg Jig, it is important to pre-drill pilot holes. This will prevent the wood from splitting and ensure a strong joint. The Kreg Jig comes with a drill bit and stop collar that can be set to the correct depth for the screw you are using.

Clamp the Wood

To ensure a tight joint, it is important to clamp the wood before drilling the pocket holes. This will prevent the wood from shifting and ensure that the pocket holes are drilled in the correct location.

Choose the Right Jig

There are different Kreg Jigs available for different applications. The Kreg Jig K4 is a popular choice for woodworking projects, while the Kreg Jig R3 is a great option for DIY projects. Choose the jig that is right for your project.

In conclusion, using the Kreg Jig can make woodworking and DIY projects easier and more efficient. By following these tips, woodworkers can ensure a strong and secure joint every time.

Frequently Asked Questions

What are the differences between pocket hole screws and regular screws?

Pocket hole screws are designed specifically for use with pocket holes made by Kreg jigs. They have a self-tapping tip and a square driver head that fits perfectly into the pocket hole. Regular screws, on the other hand, are designed for general use and do not have the same self-tapping feature or square driver head.

What size pocket hole screws should I use?

The size of pocket hole screws you should use depends on the thickness of the material you are joining. For example, for 1/2 inch material, use 1 inch screws; for 3/4 inch material, use 1-1/4 inch screws; for 1-1/2 inch material, use 2-1/2 inch screws. Always refer to the manufacturer’s recommendations for the specific jig you are using.

Can I use deck screws instead of pocket hole screws?

While it is possible to use deck screws instead of pocket hole screws, it is not recommended. Deck screws do not have the same self-tapping feature or square driver head as pocket hole screws, which can lead to splitting or cracking of the wood. Additionally, pocket hole screws are specifically designed to work with the Kreg jig, which ensures a strong and secure joint.

What are the advantages of using pocket hole screws?

Pocket hole screws offer several advantages over traditional joinery methods. They create a strong and secure joint that is hidden from view, resulting in a cleaner and more professional appearance. They are also quick and easy to use, requiring no clamps or glue. Additionally, pocket hole joinery allows for easy disassembly and reassembly, making it ideal for furniture and other projects that may need to be moved or adjusted.

Are there any alternatives to using Kreg screws with a Kreg jig?

While Kreg screws are specifically designed to work with Kreg jigs, there are alternative pocket hole screws available on the market. However, it is important to ensure that the screws you choose are compatible with your specific jig and driver. Always refer to the manufacturer’s recommendations for the best results.