Kreg screws are a popular choice for woodworkers and DIY enthusiasts. These screws are designed to work with Kreg Jigs and create strong, tight joints in a variety of materials. However, one question that often comes up is whether Kreg screws will rust over time.

Understanding Kreg Screws is important to answer this question. Kreg screws are made from a high-quality steel material that is designed to resist corrosion and rust. However, the level of rust resistance can vary depending on the type of Kreg screw you are using and the conditions it is exposed to.

Indoor Vs Outdoor use can also affect the rust resistance of Kreg screws. If you are using Kreg screws for indoor projects, they are less likely to rust since they are not exposed to moisture and other elements that can cause corrosion. On the other hand, if you are using Kreg screws for outdoor projects, they are more likely to rust over time due to exposure to rain, snow, and other weather conditions.

Key Takeaways

- Kreg screws are made from a high-quality steel material that is designed to resist corrosion and rust.

- The level of rust resistance can vary depending on the type of Kreg screw you are using and the conditions it is exposed to.

- Kreg screws used for indoor projects are less likely to rust while outdoor projects are more likely to rust over time.

Understanding Kreg Screws

Kreg screws are specially designed screws that are used in pocket-hole joinery. These screws are made from high-quality steel and are available in a variety of sizes and styles to suit different applications. They are designed to work with the Kreg Jig pocket hole system, which allows you to create strong, hidden joints in your woodworking projects.

Kreg screws are available in coarse thread and fine thread varieties. Coarse thread screws are designed for use with softwoods, such as pine and cedar, while fine thread screws are designed for use with hardwoods, such as oak and maple. The coarse thread screws have a greater holding power in softwoods, while the fine thread screws provide a smoother finish in hardwoods.

Kreg screws also come with different head styles, including Maxi-Loc, Washer-Head, and Bugle-Head. The Maxi-Loc head style is designed to drive the screw straight and true every time, while the Washer-Head style provides a larger bearing surface for increased holding power. The Bugle-Head style is designed to sit flush with the surface of the wood, making it ideal for applications where a smooth finish is required.

One of the key features of Kreg screws is that they are self-tapping. This means that they have a sharp point that allows them to drill their own hole as they are driven into the wood. This makes it easy to create strong, accurate joints without the need for pre-drilling.

Kreg screws are also available with a Maxi-Loc thread design, which provides a greater holding power than standard screws. This thread design is ideal for applications where maximum strength is required, such as in heavy-duty furniture or outdoor structures.

In terms of strength, Kreg screws are designed to provide a strong, secure joint that will last for years to come. They are made from high-quality steel and are designed to resist corrosion and rust, making them ideal for use in outdoor applications.

Overall, Kreg screws are an essential component of the Kreg Jig pocket hole system. They are available in a variety of sizes and styles to suit different applications and are designed to provide a strong, secure joint that will last for years to come.

Kreg Pocket Hole Jigs

Click Here To Check The Prices On Amazon

Indoor Vs Outdoor Use

When it comes to using Kreg screws, it is important to consider the type of project and where it will be used. Indoor and outdoor environments have different conditions that can affect the screws’ performance and durability.

Indoor Use

For indoor projects, Kreg screws are suitable for most applications. The screws are made of high-quality steel and are coated with a protective layer that prevents rust and corrosion. The coating also provides a smooth finish that blends in with the wood, making it ideal for visible joints.

Outdoor Use

For outdoor projects, Kreg offers a range of screws that are specifically designed for outdoor use. These screws are coated with a special anti-corrosion layer that provides rust-resistance up to 400% greater than zinc-plated screws. They are also compatible with pressure-treated materials, making them ideal for decks, fences, and other outdoor structures.

It is important to note that even with the best screws, outdoor projects will still be exposed to harsh weather conditions, such as rain, snow, and extreme temperatures. Therefore, it is recommended to use additional protective measures, such as sealants or coatings, to prolong the life of the project.

Kreg screws are suitable for both indoor and outdoor projects. However, for outdoor use, it is recommended to use screws that are specifically designed for outdoor conditions. By considering the environment and using the appropriate screws and protective measures, Kreg joinery projects can last for years to come.

Corrosion and Rust Resistance

Kreg screws are known for their durability and strength, but what about their resistance to corrosion and rust? Corrosion is the gradual destruction of a metal due to chemical reactions with its environment, while rust is a specific type of corrosion that occurs when iron or steel is exposed to oxygen and moisture.

Kreg screws are made of high-quality steel, which is naturally prone to rust and corrosion. However, Kreg uses a special coating on their screws to protect them from these elements. This coating is a combination of zinc and yellow chromate, which provides excellent corrosion and rust resistance.

In addition to the coating, Kreg screws are also designed with a unique thread pattern that helps to reduce the amount of torque required to drive the screw into the wood. This not only makes the screws easier to use, but it also reduces the risk of the screw head stripping or breaking off, which can lead to rust and corrosion.

It is important to note that while Kreg screws are highly resistant to rust and corrosion, they are not completely immune. If the coating is scratched or damaged, the steel underneath can be exposed to moisture and oxygen, which can lead to rust and corrosion. It is also important to use the right type of Kreg screw for the job, as using a screw that is too short or too long can increase the risk of rust and corrosion.

Overall, Kreg screws are a reliable and durable option for woodworking projects, with excellent corrosion and rust resistance thanks to their special coating and unique thread pattern. However, it is still important to take proper care of the screws and use them correctly to ensure their longevity and performance.

Kreg Screws for Different Materials

Kreg screws come in different sizes and types to suit different materials and applications. When choosing the right Kreg screw for your project, you need to consider the thickness of the material, the type of material, and the location of the project.

Thickness of the Material

The thickness of the material is one of the most important factors to consider when choosing the right Kreg screw. Kreg screws come in different lengths, ranging from 1 inch to 2 1/2 inches, to accommodate different material thicknesses. The screw length should be slightly less than the combined thickness of the two materials being joined, so that the screw does not poke through the other side.

To determine the right screw length for your project, you can use the Kreg Screw Selector Tool. This tool helps you choose the right screw length based on the thickness of the material, the type of material, and the joint you are making.

Types of Material

Kreg screws are designed for use with different types of materials, including softwoods, hardwoods, composites, and sheet goods. The type of material you are using will determine the type of screw you need.

For softwoods like pine and cedar, you can use Kreg’s Zinc Pocket-Hole Screws. These screws are designed for use with softwoods and other light-duty applications. For hardwoods like oak and maple, you can use Kreg’s Blue-Kote Pocket-Hole Screws. These screws are specially coated to resist corrosion and are ideal for use with hardwoods and other heavy-duty applications.

Location of the Project

The location of the project is another factor to consider when choosing the right Kreg screw. If your project will be exposed to moisture or humidity, you should use Kreg’s Stainless Steel Pocket-Hole Screws. These screws are made from high-quality stainless steel and are resistant to rust and corrosion. For indoor projects, you can use Kreg’s Coarse-Thread Pocket-Hole Screws. These screws are designed for use with drywall, MDF, and other interior materials.

In conclusion, Kreg screws are designed to work with different materials and applications. By considering the thickness of the material, the type of material, and the location of the project, you can choose the right Kreg screw for your needs.

Alternatives to Kreg Screws

While Kreg screws are a popular choice for woodworking projects, there are alternatives available that may suit your needs better. Here are some options to consider:

Deck Screws

Deck screws are a great alternative to Kreg screws, especially for outdoor projects. They are designed to resist rust and corrosion, making them ideal for use in harsh environments. Deck screws also have a larger diameter than Kreg screws, providing greater holding strength.

Self-Tapping Screws

Self-tapping screws are another option to consider. These screws are designed to create their own threads as they are driven into the wood, eliminating the need for pre-drilling. They are available in a variety of sizes and lengths, making them suitable for a wide range of projects.

Square Bit Torx Head Screws

Square bit Torx head screws are another alternative to Kreg screws. These screws are designed for use with Kreg jigs and offer several advantages over traditional Kreg screws. First, they are significantly more durable and less likely to strip out. They also have a larger diameter, providing greater holding strength.

Drywall Screws

Drywall screws can also be used as an alternative to Kreg screws. They are readily available and come in a variety of sizes and lengths. However, they are not as strong as Kreg screws and may not be suitable for heavy-duty projects.

When choosing an alternative to Kreg screws, it’s important to consider the specific needs of your project. Consider the type of wood you are working with, the environment in which the project will be located, and the amount of holding strength required. With these factors in mind, you can choose the best alternative to Kreg screws for your project.

Kreg Tools and Accessories

Kreg Tool Company is a well-known manufacturer of tools and accessories for woodworking projects. Their product line includes pocket-hole screws, pocket-hole jigs, pocket-hole machines, square-drive bits, and more.

Kreg pocket-hole screws are designed to work with their pocket-hole jigs and machines. These screws are available in a variety of lengths and finishes, including zinc-plated and Blue-Kote™ coated screws. The Blue-Kote™ coating provides rust-resistance up to 400% greater than zinc-plated screws, making them ideal for use with pressure-treated material. Kreg recommends using the correct length of screw to ensure a strong and secure joint. For a standard 2×4, which is 1.5 inches thick, Kreg recommends using 2.5-inch pocket-hole screws.

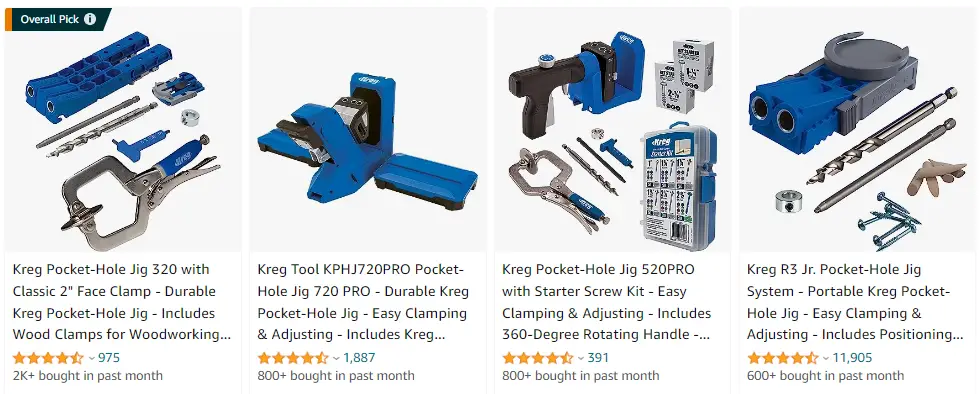

Kreg pocket-hole jigs are used to create pocket holes for the screws to be inserted into. These Jigs are available in a variety of sizes and styles, including the Kreg® Pocket-Hole Jig 320, Kreg® Pocket-Hole Jig 720, and Kreg® Pocket-Hole Jig K5. Each jig is designed to make it easy to create pocket holes at the correct angle and depth for the screw being used.

Kreg pocket-hole machines are designed for high-volume production of pocket holes. These machines are available in two models, the Foreman Pocket-Hole Machine and the DK1100 FP. The Foreman is a benchtop machine that can create up to 240 pocket holes per hour, while the DK1100 FP is a floor-standing machine that can create up to 1,100 pocket holes per hour.

Kreg square-drive bits are designed to work with their pocket-hole screws. These bits are available in a variety of sizes, including #1, #2, and #3. The #2 bit is the most commonly used size and is included with most Kreg pocket-hole jigs.

Overall, Kreg tools and accessories are designed to work together to make it easy to create strong and secure pocket-hole joints. Whether you are a professional woodworker or a DIY enthusiast, Kreg has the tools and accessories you need to get the job done right.

Cost and Availability

When it comes to the cost of Kreg screws, it can vary greatly depending on the type of material used to build the project. The Kreg system offers a range of screws, including coated and zinc-plated screws. Coated screws provide rust-resistance up to 400% greater than zinc-plated screws and work well with pressure-treated material. Zinc screws provide adequate rust protection and serve as an affordable alternative to the more protective Blue-Kote™ and stainless screw varieties.

Replacement parts for Kreg screws are available directly from Kreg. Customers can purchase Kreg screws from various retailers, including the Kreg Tool Company website, Amazon, and Home Depot. The availability of Kreg screws may vary depending on the retailer and location.

For those looking for alternatives to Kreg jig pocket hole screws, there are options available. Some people prefer to use screws they already have on hand, while others may opt for cheaper alternatives. However, it is important to note that using screws that are not specifically designed for pocket hole joinery may compromise the strength and durability of the project.

Overall, the cost and availability of Kreg screws are factors to consider when deciding whether to use the Kreg system for a project. While there are alternatives available, it is important to use screws that are designed for pocket hole joinery to ensure the strength and durability of the project.

Zinc Coated Kreg Screws

Kreg screws are designed to be strong and durable, but will they rust over time? Kreg offers a variety of screws, including zinc-coated options that provide additional protection against rust and corrosion.

Zinc is a popular coating for screws because it is relatively inexpensive and provides good protection against rust. Zinc-coated Kreg screws are created by electroplating the screws with a layer of zinc. This layer of zinc acts as a barrier between the metal of the screw and the surrounding environment, preventing rust and corrosion from forming.

While zinc-coated Kreg screws are designed to be rust-resistant, they are not completely immune to rust. If the zinc coating is scratched or damaged, the underlying metal can be exposed to the elements and begin to rust. Additionally, if the screws are used in a particularly harsh environment, such as near saltwater, they may be more susceptible to rust and corrosion.

To ensure the longevity of zinc-coated Kreg screws, it is important to use them in the right applications and to take proper care of them. If the screws will be exposed to moisture or saltwater, it may be best to use stainless steel screws instead. Additionally, it is important to store the screws in a dry environment to prevent any moisture from accumulating on the surface of the screws.

Zinc-coated Kreg screws are a good option for those looking for a durable and rust-resistant screw. However, they are not completely immune to rust and should be used in the appropriate applications and stored properly to ensure their longevity.

Frequently Asked Questions

What type of screws are best for outdoor use?

When it comes to outdoor use, it’s important to choose screws that are resistant to rust and corrosion. Kreg Blue-Kote™ Screws are a great option for outdoor projects as they feature three anti-corrosion layers, providing rust-resistance up to 400% greater than zinc-plated screws.

How do Kreg screws compare to regular screws?

Kreg screws are specifically designed for use with pocket hole joinery, which creates a strong and secure joint without the need for additional clamps or fasteners. Regular screws may not provide the same level of strength and stability as Kreg screws, especially when used for pocket hole joinery.

Should I use glue in addition to Kreg screws?

While Kreg screws alone can create a strong and secure joint, adding glue can provide even more strength and stability. However, it’s important to use the right type of glue and to apply it correctly for the best results.

What size Kreg screws should I use for 3/4 inch material?

For 3/4 inch material, Kreg recommends using 1-1/4 inch screws. It’s important to choose the right length of screw to ensure a strong and secure joint. Using a screw that is too short may not provide enough holding power, while using a screw that is too long may cause the material to split.