Screws are an essential part of woodworking projects. They are used to join two pieces of wood together and hold them firmly in place. However, there are different types of screws available, and choosing the right one for a particular project can be a daunting task. Two of the most popular screw types used in woodworking are regular screws and Kreg screws.

Regular screws are the most commonly used screws in woodworking projects. They are versatile and can be used for a wide range of applications. Regular screws come in different sizes, lengths, and materials. They are easy to find in hardware stores and are relatively inexpensive. On the other hand, Kreg screws are specifically designed for use with pocket-hole joinery. They are self-tapping screws that come with a special head that fits snugly into the pocket hole.

Understanding the difference between Kreg screws and regular screws is essential for any woodworking enthusiast. While regular screws are versatile and can be used for different applications, Kreg screws are specifically designed for pocket-hole joinery. Kreg screws come in different sizes and materials and are known for their strength and durability. It is important to choose the right screw for a particular project to ensure a strong and long-lasting joint.

Key Takeaways

- Regular screws are versatile and can be used for a wide range of applications, while Kreg screws are specifically designed for pocket-hole joinery.

- Kreg screws are self-tapping screws that come with a special head that fits snugly into the pocket hole.

- Choosing the right screw for a particular project is essential for ensuring a strong and long-lasting joint.

Understanding Screws

Screws are one of the most commonly used fasteners in woodworking and construction. They come in various sizes, shapes, and materials, and each type of screw is designed for a specific purpose. In this section, we will cover the basic components of screws and the different types of screws available in the market.

Basic Components of Screws

All screws have three basic components: the head, the shank, and the thread. The head is the top part of the screw that is used to turn it. The shank is the straight part of the screw that goes into the material. The thread is the spiral-shaped ridge that wraps around the shank and is used to grip the material.

The head of the screw can be flat, oval, or round, and it can be slotted, Phillips, or hexagonal in shape. The shank can also be smooth or threaded, depending on the type of screw. The thread can be coarse or fine, and it can be designed for specific materials such as wood, metal, or plastic.

Types of Screws

There are many different types of screws available in the market, each designed for a specific purpose. Here are some of the most common types of screws:

- Wood Screws: These screws are designed for use in wood and have a tapered shank and a sharp point. They come in various sizes and lengths and can be used for a variety of woodworking projects.

- Deck Screws: These screws are designed for use in outdoor decking projects and are made of corrosion-resistant materials such as stainless steel or coated with a rust-resistant finish.

- Drywall Screws: These screws are used for attaching drywall to wood or metal studs. They have a bugle head and a sharp point and are available in various lengths.

- Self-Tapping Screws: These screws are designed to tap their own threads in materials such as metal or plastic. They have a sharp point and a thread that is designed to cut through the material.

- Kreg Pocket Hole Screws: These screws are specially designed for use with the Kreg pocket hole jig system. They have a flat-bottomed head and a deep thread that is designed to pull the joint together tightly.

- Pocket Hole Screws: These screws are designed for use in pocket-hole joinery and have a self-tapping thread that is designed to create a strong joint between two pieces of wood.

In summary, screws are an essential component in woodworking and construction projects. Understanding the basic components of screws and the different types available can help you choose the right screw for your project and ensure a strong and secure joint.

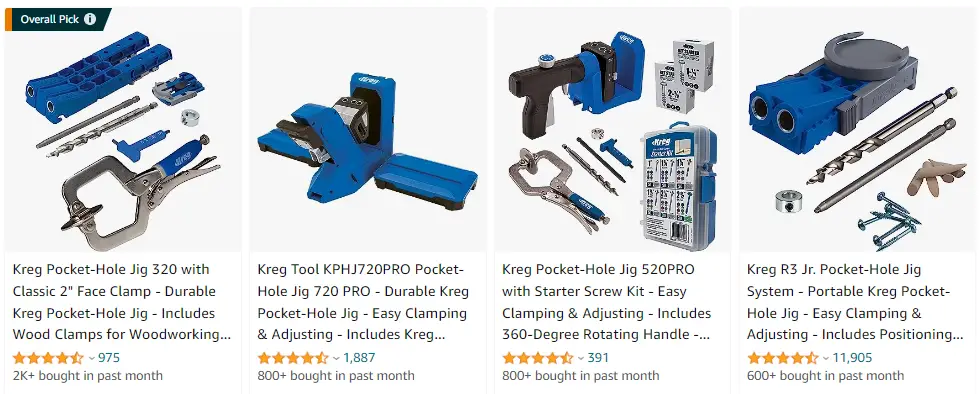

Kreg Pocket Hole Jigs

Click Here To Check The Prices On Amazon

Kreg Screws Overview

Kreg Jig

The Kreg Jig is a tool that allows woodworkers to join two pieces of wood together using pocket-hole joinery. A pocket hole is a hole drilled at a specific angle into one piece of wood that allows a screw to be driven into the other piece of wood at a specific angle. The Kreg Jig makes it easy to create pocket holes at the correct angle and depth.

Kreg Screw Types

Kreg Screws are specifically designed for use with the Kreg Jig and pocket-hole joinery. They come in a variety of types and sizes, each designed for a specific type of wood and application. Some of the most common Kreg Screw types include:

- Coarse-Thread Screws: These screws are designed for use with softwoods like pine, cedar, and spruce. They have a larger thread pitch that helps them grip the softer wood fibers.

- Fine-Thread Screws: These screws are designed for use with hardwoods like oak, maple, and cherry. They have a smaller thread pitch that helps prevent the wood from splitting.

- Outdoor Screws: These screws are made from a special type of steel that is resistant to corrosion, making them ideal for use in outdoor projects.

- Maxi-Loc Screws: These screws are designed to be used with the Kreg Jig HD, which is used for joining thicker pieces of wood.

Kreg Screws are available in a range of lengths, from 1″ to 2 1/2″, and in a variety of head styles, including pan head, washer head, and trim head. The right type of Kreg Screw for a specific project will depend on the type of wood being used, the thickness of the wood, and the application.

In summary, Kreg Screws are specifically designed for use with the Kreg Jig and pocket-hole joinery. They come in a variety of types and sizes, each designed for a specific type of wood and application. When used correctly, Kreg Screws can create strong, durable joints that will last for years to come.

Materials and Screws

When it comes to choosing the right screws for your woodworking projects, it is important to consider the type of material you are working with. Different materials require different types of screws, and this is especially true when it comes to Kreg screws versus regular screws.

Wood and Screws

When working with wood, it is important to choose the right type of screw for the job. For softwoods such as fir, pine, and cedar, a coarse-thread screw is generally recommended. These screws have a greater pitch and are better suited for softer materials.

For hardwoods such as cherry, maple, and oak, a fine-thread screw is generally recommended. These screws have a tighter pitch and are better suited for denser materials.

Material Thickness and Screws

Another important factor to consider when choosing screws is the thickness of the material you are working with. For thinner materials, such as sheet goods and plywood, a fine-thread screw is generally recommended. These screws have a tighter pitch and are better suited for thinner materials.

For thicker materials, such as treated lumber and MDF, a coarse-thread screw is generally recommended. These screws have a greater pitch and are better suited for thicker materials.

In summary, when choosing screws for your woodworking projects, it is important to consider the type of material you are working with and the thickness of that material. By selecting the right type of screw for the job, you can ensure a strong and secure connection that will last for years to come.

Thread Types and Their Uses

When it comes to screws, thread type is an important factor to consider. The two main types of thread are coarse and fine. Each type has its own unique characteristics that make it more suitable for certain applications.

Coarse-Thread Screws

Coarse-thread screws have a larger thread pitch and deeper threads than fine-thread screws. This makes them ideal for use in softer materials such as wood or plastic. The larger threads provide more grip and hold the screw in place better than fine-thread screws. Coarse-thread screws are also less likely to strip or break when used in softer materials.

However, coarse-thread screws may not be suitable for use in harder materials such as metal. The larger threads may not be able to grip the material as well, which can cause the screw to strip or break. In these cases, fine-thread screws may be a better option.

Fine-Thread Screws

Fine-thread screws have a smaller thread pitch and shallower threads than coarse-thread screws. This makes them ideal for use in harder materials such as metal. The smaller threads are able to grip the material more effectively, providing a stronger hold than coarse-thread screws.

Fine-thread screws are also less likely to split the material they are being screwed into. This makes them a good choice for use in thin or delicate materials.

However, fine-thread screws may not be suitable for use in softer materials such as wood or plastic. The smaller threads may not be able to grip the material as well, which can cause the screw to slip or strip.

In summary, when choosing between coarse-thread and fine-thread screws, it is important to consider the material being used and the application. Coarse-thread screws are better suited for use in softer materials, while fine-thread screws are better suited for use in harder materials.

Indoor and Outdoor Projects

When it comes to choosing the right screws for your project, it’s important to consider whether it will be an indoor or outdoor project. Using the wrong type of screw can lead to a weak joint or even rust and corrosion over time.

Indoor Project Screws

For indoor projects, regular screws can be used, but Kreg screws are often preferred for their ability to create strong and hidden joints. Kreg screws come in a variety of sizes and finishes, so it’s important to choose the right one for your project.

When selecting screws for indoor projects, it’s important to consider the type of material you’ll be working with. For example, softwoods like pine and cedar may require a different screw than hardwoods like oak and maple. Kreg’s Screw Selector Tool can help you choose the right screw based on the type of material you’re working with.

Outdoor Project Screws

Outdoor projects require screws that can withstand the elements, especially moisture. Kreg’s Blue-Kote™ Pocket-Hole Screws are a great choice for outdoor projects, as they are specially designed to resist corrosion in wet areas. These screws feature three anti-corrosion layers, making them ideal for use in projects for your porch, patio, detached garage, or other outdoor areas.

When selecting screws for outdoor projects, it’s important to consider the type of material you’ll be working with and the location of the project. For example, if the project will be exposed to direct sunlight, it may be best to choose a screw with a UV-resistant finish to prevent fading and discoloration over time.

Overall, choosing the right screws for your project is essential for creating a strong and long-lasting joint. Whether you’re working on an indoor or outdoor project, Kreg screws offer a variety of options to help you achieve the best results.

Screw Head Styles and Functions

When it comes to screws, one of the most important aspects to consider is the head style. Different head styles have different functions and are designed for specific applications. In this section, we’ll take a closer look at two common screw head styles: Phillips head and pan-head screws.

Phillips Head

The Phillips head is one of the most popular screw head styles and is used in a wide range of applications. It features a cross-shaped indentation in the head that is designed to be used with a Phillips screwdriver. The Phillips head is designed to provide more torque than a slotted head, making it easier to drive the screw into the material. It is commonly used in woodworking and other applications where a strong, reliable connection is required.

Pan-Head Screws

Pan-head screws are another common screw head style that is used in a variety of applications. They feature a flat, rounded head that is slightly larger in diameter than the screw shank. This design provides a wider bearing surface, which helps to distribute the load and prevent the screw from pulling through the material. Pan-head screws are commonly used in sheet metal, plastic, and other thin materials.

In summary, understanding the different screw head styles and their functions is essential when selecting the right screw for your project. The Phillips head provides more torque and is commonly used in woodworking, while pan-head screws have a wider bearing surface and are commonly used in thin materials.

Screw Selection and Uses

When it comes to choosing screws for woodworking projects, there are a lot of options available. Kreg screws and regular screws are two popular choices, but what are the differences between them? In this section, we will explore screw selection and uses, including the Kreg Screw Selector Tool and the applications of different types of screws.

Screw Selector Tool

The Kreg Screw Selector Tool is a useful resource for selecting the right screw for your project. This tool takes into account the thickness of the material you are using, the type of material, and the application of the project. It also considers whether the project will be used indoors or outdoors, as screws for outdoor use need to be made from durable material that can withstand the elements.

The Screw Selector Tool is available online or in hardware stores and can be used to determine the best screw for your project. The tool includes a screw selector wheel that allows you to choose the type of screw you need based on the thickness of the material you are using.

Screw Uses and Applications

Different types of screws have different uses and applications. Coarse-threaded screws are ideal for softwoods, while fine-threaded screws are better suited for hardwoods. Kreg Pocket-Hole Screws are designed for use with pocket-hole joinery and are available in a variety of lengths and thread types.

Zinc-coated screws are suitable for use in kitchens and bathrooms, while Blue-Kote™ Kreg Pocket-Hole Screws are the best choice for damp or wet applications, including projects for your porch, patio, detached garage, or outdoor areas. These screws feature three anti-corrosion layers to help them resist corrosion in wet areas for the long haul.

When selecting screws for your project, it is important to consider the type of material you are working with, the thickness of the material, and the application of the project. The Kreg Screw Selector Tool is a useful resource for selecting the right screw for your project, and hardware stores carry a variety of associated products to help you complete your project with ease.

Special Features of Kreg Screws

Kreg screws are designed specifically for pocket-hole joinery. They are different from regular screws in several ways, including their self-tapping tip and Blue-Kote™ coating.

Self-Tapping Tip

Kreg screws feature a self-tapping tip that eliminates the need for pre-drilling. This means that you can drill your pocket holes and drive your screws in one step, saving time and effort. The self-tapping tip also helps prevent splitting of the wood, which can be a common problem with regular screws.

Blue-Kote™ Screws

Kreg Blue-Kote™ screws are coated with a proprietary three-step coating process that provides excellent corrosion resistance. The first step is a zinc coating that provides a barrier against moisture. The second step is a blue chromate conversion coating that further enhances the corrosion resistance. The final step is a clear topcoat that adds additional protection against wear and tear.

Blue-Kote™ screws are ideal for use in outdoor projects or in environments where moisture is a concern. They are also great for use in projects where appearance is important, as the blue coating blends in nicely with most types of wood.

In addition to their special features, Kreg screws are available in a variety of lengths and thread types to suit different applications. They are also available in zinc-coated and stainless steel versions for added durability and corrosion resistance.

Overall, Kreg screws are an excellent choice for anyone looking to build strong, long-lasting joints quickly and easily.

Strength and Durability of Screws

When it comes to choosing between Kreg screws and regular screws, one of the most important factors to consider is the strength and durability of the screws. Both types of screws are designed to hold materials together, but they differ in terms of their holding power and resistance to external forces.

Kreg screws are known for their superior strength and durability compared to regular screws. This is because Kreg screws are made of high-quality steel that is specially hardened to prevent the screw from snapping or breaking during installation. The steel is also case-hardened, which forms a tough outer shell to make the screw durable, while keeping the core softer to prevent the screw from becoming brittle. This means that Kreg screws provide a strong and secure hold, even under heavy loads and in harsh environments.

Regular screws, on the other hand, are typically made of softer steel and may not be as durable as Kreg screws. They may be prone to snapping or breaking under heavy loads or when exposed to harsh weather conditions. This can compromise the integrity of the material being held together, leading to potential safety hazards and costly repairs.

When it comes to holding power, Kreg screws are also known to be superior to regular screws. This is because Kreg screws feature a unique design that includes a self-tapping tip and deep threads that grip the material tightly, providing a strong and secure hold. Regular screws, on the other hand, may not be able to grip the material as tightly, leading to a weaker hold and potentially compromising the structural integrity of the material.

In terms of materials, Kreg screws are available in a variety of finishes, including stainless steel, which provides added resistance to corrosion and rust. This makes them ideal for use in outdoor projects or in environments where moisture and humidity are present. Regular screws may also be available in stainless steel, but they may not offer the same level of resistance to corrosion and rust as Kreg screws.

Overall, when it comes to strength and durability, Kreg screws are the clear winner. Their unique design, high-quality steel, and resistance to external forces make them ideal for use in a wide range of applications, from simple DIY projects to complex construction projects.

Pocket-Hole Joinery

Pocket-hole joinery is a simple and effective method of joining wood pieces together using pocket hole screws. This type of joinery is also known as pocket-hole joinery or pocket screw joinery. It involves drilling a hole at an angle into one piece of wood, and then driving a pocket hole screw into the hole and into the adjoining piece of wood.

Pocket-hole joinery is popular because it is fast, easy, and requires minimal tools. It is also a strong and reliable method of joinery, especially when used in conjunction with glue. Pocket-hole joinery is often used in furniture-making, cabinet-making, and other woodworking projects.

One of the key benefits of pocket-hole joinery is that it allows you to create strong joints quickly and easily, without the need for advanced woodworking skills or expensive tools. Pocket hole screws are designed to be used specifically with pocket-hole joinery, and they have several features that make them different from regular screws.

For example, pocket hole screws have a self-tapping design that allows them to create their own pilot hole as they are driven into the wood. They also have a flat-bottomed head that sits flush with the surface of the wood, which helps to prevent splitting and ensures a strong joint.

Overall, pocket-hole joinery is a versatile and reliable method of joinery that is well-suited for a wide range of woodworking projects. Whether you are a beginner or an experienced woodworker, pocket-hole joinery can help you create strong and beautiful pieces of furniture and other woodworking projects.

Woodworking Projects and Screws

When it comes to woodworking projects, choosing the right screws is crucial. The type of screw used can affect the function and durability of the project. Regular screws are commonly used in woodworking, but Kreg screws are becoming increasingly popular due to their unique design.

Beginners in woodworking may find regular screws easier to work with as they are readily available and can be used on a variety of surfaces. However, Kreg screws are specifically designed for pocket-hole joinery, which allows for a stronger and more secure joint.

One factor to consider when choosing screws for woodworking projects is the possibility of exposure to moisture or corrosive elements. In such cases, it is best to use screws made from durable materials that can withstand these conditions. Kreg offers a selection of screws specifically designed for outdoor projects that are made from weather-resistant materials.

In summary, regular screws can be used for a variety of woodworking projects, but Kreg screws are specifically designed for pocket-hole joinery and can provide a stronger and more secure joint. When working on projects that may be exposed to moisture or corrosive elements, it is best to use screws made from durable materials that can withstand these conditions.

Maxi-Loc Screws

Maxi-Loc screws are a type of Kreg screw that are commonly used in pocket-hole joinery. They have a large head that provides maximum bearing surface as the screw pulls tight in the pocket. This makes them a great choice for the majority of applications.

One of the benefits of Maxi-Loc screws is that they are easy to use. They have a self-tapping design that allows them to be driven directly into the wood without the need for pre-drilling. This can save a lot of time and effort, especially when working on larger projects.

Another advantage of Maxi-Loc screws is that they are available in a variety of lengths and thread types. This makes it easy to find the right screw for the job, whether you are working with softwoods, hardwoods, sheet goods, or treated lumber.

When selecting Maxi-Loc screws, it is important to consider the thickness of the material you are using, as well as the type and where you will place the project. For example, if you are working with dense hardwoods or 1/2″ thick stock, you may want to consider using Pan-Head screws instead.

Overall, Maxi-Loc screws are a versatile and reliable choice for pocket-hole joinery. They are easy to use, available in a variety of sizes and thread types, and provide maximum bearing surface for a strong and secure joint.