Kreg screws are a popular choice among woodworkers, and one of the most distinctive features of these screws is their blue color. Many people may wonder why Kreg screws are blue, and this article will answer that question. Understanding the reason behind the blue color of Kreg screws can provide insight into the manufacturing process and the unique properties of these screws.

The Kreg brand is known for its innovative pocket hole joinery system, which allows woodworkers to create strong and long-lasting joints quickly and easily. Kreg screws are an essential component of this system, and they are designed to work seamlessly with Kreg jigs and other associated products.

While Kreg screws come in a variety of sizes and shapes, they all share the same blue color. Understanding why Kreg screws are blue can help woodworkers choose the right screws for their projects and ensure that their joints are strong and durable.

Key Takeaways

- Kreg screws are an essential component of the Kreg pocket hole joinery system, which is known for its strength and durability.

- Kreg screws are blue because of a special anti-corrosion coating that helps protect them from rust and other types of damage.

- Understanding the unique properties of Kreg screws, including their blue color, can help woodworkers create long-lasting joints and achieve professional-quality results.

The Kreg Brand

Kreg is a well-known brand that produces high-quality woodworking tools and accessories. Founded in 1986, the company has been providing innovative solutions to woodworkers for over three decades. The brand is known for its pocket hole joinery system, which has revolutionized the way woodworkers join pieces of wood together.

Kreg’s pocket hole joinery system is based on a simple concept. By drilling a hole at an angle into one piece of wood and joining it to another piece of wood with a screw, a strong and durable joint is created. The system is easy to use and can be used for a variety of woodworking projects, from simple picture frames to complex cabinets.

Kreg’s success can be attributed to its commitment to quality and innovation. The company is constantly developing new products and improving existing ones to meet the needs of woodworkers. Kreg’s products are designed to be easy to use, reliable, and durable, making them a favorite among woodworkers of all skill levels.

In addition to its pocket hole joinery system, Kreg produces a wide range of other woodworking tools and accessories. These include clamps, saw guides, router tables, and more. All of Kreg’s products are designed to work together seamlessly, allowing woodworkers to create high-quality projects with ease.

Overall, Kreg is a brand that is synonymous with quality and innovation in the woodworking industry. Its products are trusted by woodworkers around the world, and its commitment to excellence has made it a leader in the industry.

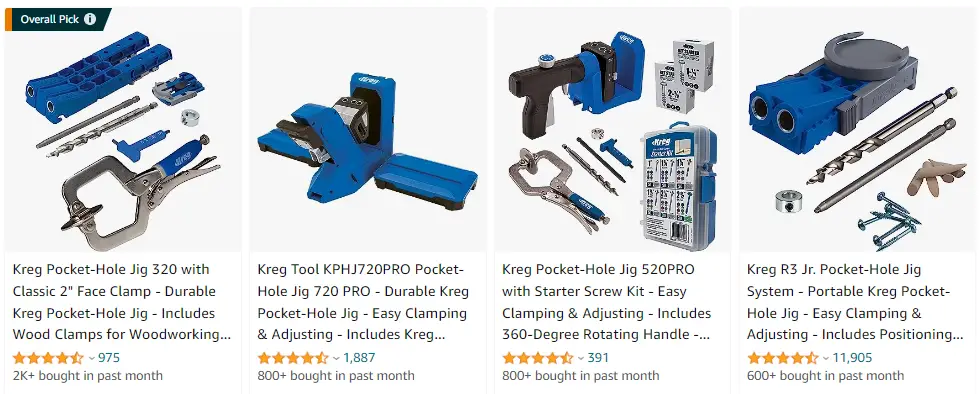

Kreg Pocket Hole Jigs

Click Here To Check The Prices On Amazon

Understanding Kreg Screws

Kreg screws are specially designed screws that are used in conjunction with Kreg Jigs to create strong and durable joints in woodworking projects. These screws are available in a variety of sizes, finishes, and thread types to suit different applications and materials.

One of the most distinctive features of Kreg screws is their blue coating. This coating is known as Blue-Kote™ and is designed to provide superior rust and corrosion resistance, making Kreg screws ideal for use in outdoor and damp environments.

Kreg screws are made from high-quality steel and are specially designed to work with the Kreg Jig system. They feature a unique self-tapping design that allows them to create a strong and secure joint without the need for pre-drilling. This makes them faster and easier to use than traditional wood screws.

In addition to the Blue-Kote™ finish, Kreg screws are also available in zinc-coated and stainless-steel finishes. Zinc-coated screws are suitable for use in kitchens and bathrooms, while stainless-steel screws are ideal for marine and other high-corrosion environments.

Kreg screws are available in a range of sizes to suit different materials and applications. The most common sizes are 1-1/4″, 1-1/2″, and 2-1/2″ lengths, with thread sizes ranging from #6 to #14. Kreg screws are also available in fine and coarse thread types to suit different materials and applications.

Overall, Kreg screws are an essential component of the Kreg Jig system and are a must-have for any serious woodworker. With their unique self-tapping design, superior corrosion resistance, and range of sizes and finishes, Kreg screws are the perfect choice for creating strong and durable joints in all your woodworking projects.

Why Kreg Screws Are Blue

Kreg Screws are known for their distinctive blue color, which sets them apart from other types of screws. But why are Kreg Screws blue?

The answer lies in the type of coating that is applied to these screws. Kreg Screws are coated with a special type of blue-colored coating called Blue-Kote™. This coating is designed to provide extra protection against corrosion and rust, making these screws ideal for use in damp or wet environments.

The Blue-Kote™ coating is made up of three anti-corrosion layers that help to prevent rust and corrosion from forming on the surface of the screw. The first layer is a zinc-nickel alloy that provides a barrier against moisture and other corrosive elements. The second layer is a chromate coating that provides additional protection against rust and corrosion. The third and final layer is the blue-colored polymer coating that gives the screw its distinctive color.

The Blue-Kote™ coating is not only functional but also aesthetically pleasing. The blue color of the coating is designed to blend in with the natural wood grain of the material being used, making the screws less visible and creating a more professional-looking finish.

In addition to their corrosion resistance and aesthetic appeal, Blue-Kote™ screws are also incredibly strong and durable. They are made from high-quality steel that has been case-hardened to provide extra strength and durability. This means that they can be used in a wide range of applications, from building furniture to constructing outdoor structures.

Overall, the Blue-Kote™ coating on Kreg Screws provides a number of benefits that make these screws an excellent choice for any woodworking project. Whether you are building furniture, constructing outdoor structures, or working on any other woodworking project, Kreg Screws with Blue-Kote™ coating are sure to provide the strength, durability, and protection you need to get the job done right.

The Role of Anti-Corrosion Layers

Kreg screws are known for their blue coating, which is actually an anti-corrosion layer that protects the screws from rust and other forms of corrosion. The blue coating is called Blue-Kote and it is a proprietary coating developed by Kreg.

The role of anti-corrosion layers is to protect metal from the damaging effects of corrosion. Corrosion occurs when metal is exposed to moisture and oxygen, which causes it to break down and deteriorate over time. Anti-corrosion layers work by creating a barrier between the metal and the environment, preventing moisture and oxygen from coming into contact with the metal.

Blue-Kote is a three-layer coating that provides up to 400% more rust resistance than zinc-plated screws, making it the perfect choice for both indoor and outdoor projects. The first layer is a zinc-nickel alloy that provides a base layer of protection against corrosion. The second layer is a chromate conversion coating that enhances the corrosion resistance of the zinc-nickel alloy. The third layer is a blue organic polymer coating that provides additional protection against corrosion and also makes the screws easier to drive.

Blue-Kote screws are suitable for use with pressure-treated material and are available in a variety of sizes and quantities. They are an ideal choice for outdoor garden and patio furniture, as well as for general exterior construction.

In addition to Blue-Kote, there are other types of anti-corrosion coatings that are commonly used in the construction industry. These include zinc plating, galvanizing, and powder coating. Each of these coatings has its own unique properties and advantages, and the choice of coating will depend on the specific application and environment in which the screws will be used.

Indoor Vs Outdoor Applications

When it comes to selecting the right pocket-hole screws, it is important to consider the application for which they will be used. Kreg pocket-hole screws are suitable for both indoor and outdoor projects, but different screws may be required depending on the application.

For indoor projects, zinc-coated screws are a good choice. These screws are resistant to corrosion and are suitable for use in kitchens and bathrooms. Maxi-Loc screws are a great choice for the majority of indoor applications. They have a large head that provides maximum bearing surface as the screw pulls tight in the pocket.

For outdoor applications, Blue-Kote™ Kreg Pocket-Hole Screws are the best choice. These screws feature three anti-corrosion layers to help them resist corrosion in wet areas for the long haul. They are perfect for use in projects for your porch, patio, detached garage, or outdoor areas. Blue-Kote™ Screws provide rust-resistance up to 400% greater than zinc-plated screws and work with pressure-treated material.

When selecting the right screw type for your application, it is important to consider the thickness of the wood you are working with. The actual thickness, not the nominal thickness, should be used. If you are working with two different thicknesses, use the smallest of the two. The screw length should also be considered. Selecting the correct screw length is the most important consideration when choosing a Kreg Screw. We suggest using the screw lengths shown in the Kreg Screw Selector when joining materials of the same thickness.

In summary, selecting the right pocket-hole screw for your project is important to ensure a strong and durable joint. For indoor projects, zinc-coated screws are a good choice, while Blue-Kote™ Kreg Pocket-Hole Screws are the best choice for outdoor applications.

The Importance of Material Thickness

When it comes to using Kreg pocket-hole jigs and screws, understanding the material thickness is crucial to creating a strong and secure joint. The easiest way to check the thickness of your material is to use the Material Thickness Gauge that comes with every new Kreg 300-, 500-, and 700-Series Pocket-Hole Jig. This gauge is easy to use and will ensure that you select the correct screw length for your project.

Plywood is a popular material for woodworking projects, but it can be tricky to work with due to its varying thicknesses. It’s important to measure the actual thickness of the plywood rather than relying on the nominal thickness listed on the label. This is because plywood can vary in thickness due to manufacturing processes and can be affected by humidity and temperature changes.

Using the correct screw length for your material thickness is essential to creating a strong and secure joint. Kreg screws come in a variety of lengths to accommodate different material thicknesses. Always be sure to use the actual thickness of your material when selecting a screw length. The Kreg Screw Selector Tool can help you choose the right screw for your project based on your material type and thickness.

When joining different thickness materials using a Kreg Jig, it’s important to adjust the collar depth of the drill bit to ensure that the pocket hole is the correct depth for the screw length. The pocket only needs to be deep enough to hide the screw head and gives you a little latitude on screw length and stock thickness. If the collar is set too deep, the pocket hole will be too deep, and the screw will not have enough material to grip onto, resulting in a weak joint.

In summary, understanding material thickness is essential to creating strong and secure joints with Kreg pocket-hole jigs and screws. Always measure the actual thickness of your material and use the Kreg Material Thickness Gauge and Screw Selector Tool to select the correct screw length for your project. With the right tools and techniques, you can create professional-quality woodworking projects with ease.

Understanding Screw Selector

When it comes to choosing the right Kreg screw for your project, it can be overwhelming to know where to start. Fortunately, Kreg offers a Screw Selector Tool that can help take the guesswork out of the process.

The Screw Selector Tool is an online resource that allows you to input information about your project, such as the type of wood you’re using and the thickness of the material. Based on this information, the tool will recommend the appropriate screw length and type to use.

One important thing to keep in mind when using the Screw Selector Tool is that it’s important to measure your material accurately. This means using the actual thickness of the wood rather than an estimated measurement. This will ensure that the screw you choose is the right length for your project.

Another consideration when selecting a screw is the type of material you’re working with. If you’re building an indoor project and moisture is not a concern, zinc screws are a good option. However, if you’re working with treated lumber or building an outdoor project, Blue-Kote™ screws are recommended for their resistance to moisture.

In addition to the Screw Selector Tool, Kreg also offers a variety of resources to help you choose the right screw for your project. These include instructional videos and articles that cover everything from selecting the right screw length to choosing the right screw type for your project.

Overall, understanding the Screw Selector Tool and the factors that go into selecting the right Kreg screw for your project can help ensure that your project is a success. By taking the time to choose the right screw, you can ensure that your project is strong, durable, and built to last.

Types of Kreg Screws

Kreg screws come in various types and sizes, each designed to suit specific woodworking needs. Here are some of the most common types of Kreg screws:

Coarse-Thread Screws

Coarse-thread screws are the most commonly used type of Kreg screws. They have a larger thread pattern that provides a stronger grip on the wood. These screws are ideal for softwoods, such as pine, cedar, and spruce.

Fine-Thread Screws

Fine-thread screws have a smaller thread pattern that provides a smoother finish. They are designed to be used on hardwoods, such as oak, maple, and cherry. These screws are less likely to split the wood and provide a cleaner finish.

Pan-Head Screws

Pan-head screws have a large, flat head with a rounded top. They are designed to be used with pocket-hole joinery and provide a strong, secure hold. These screws are ideal for joining thicker materials, such as 2x4s and 2x6s.

Maxi-Loc Screws

Maxi-Loc screws are designed for use with hardwoods and dense materials. They have a washer head that provides a larger surface area for the screw to grip onto, making them ideal for use in high-stress applications.

Zinc-Plated Screws

Zinc-plated screws are coated with a layer of zinc that provides corrosion resistance. These screws are ideal for use in indoor applications, such as furniture and cabinetry.

Zinc-Coated Screws

Zinc-coated screws are coated with a layer of zinc that provides even greater corrosion resistance than zinc-plated screws. These screws are ideal for use in outdoor applications, such as decks and fences.

Deck Screws

Deck screws are designed specifically for use in outdoor applications. They are coated with a layer of weather-resistant material that protects them from rust and corrosion. These screws are ideal for use in decking, fencing, and other outdoor projects.

In summary, Kreg screws come in a variety of types and sizes, each designed to suit specific woodworking needs. Whether you’re working with softwoods or hardwoods, indoor or outdoor projects, Kreg has a screw that will provide a strong, secure hold.

The Use of Kreg Jig

Kreg Jig is a popular pocket-hole jig used to create strong and secure joints in woodworking projects. The jig uses a drill bit to create a pocket hole at an angle, allowing the screw to be driven into the adjacent board at an angle, creating a strong joint.

To use the Kreg Jig, the user must first set the jig to the appropriate board thickness. The jig comes with a depth collar that can be adjusted to match the thickness of the board being used. Once the jig is set, the user can clamp the jig to the board and drill the pocket hole.

After drilling the pocket hole, the user can insert a Kreg screw into the pocket hole and drive it into the adjacent board using a square driver bit. The Kreg screws are specifically designed for use with the Kreg Jig and are available in course and fine thread. Course thread screws are recommended for soft woods and plywood, while fine thread screws are recommended for hard woods.

The Kreg screws are also available in different finishes, including zinc-coated and Blue-Kote. Zinc-coated screws are suitable for use in kitchens and bathrooms, while Blue-Kote screws are the best choice for damp or wet applications, including projects for your porch, patio, detached garage, or outdoor areas. These screws feature three anti-corrosion layers to help them resist corrosion in wet areas for the long haul.

In summary, the Kreg Jig is a versatile and easy-to-use pocket-hole jig that can help woodworkers create strong and secure joints in their projects. When using the Kreg Jig, it is important to use Kreg screws that are specifically designed for use with the jig, as well as to select the appropriate finish for the intended application.

Pocket Hole Joinery

Pocket hole joinery is a popular method of joining two pieces of wood together at a right angle. It involves drilling a pocket hole at an angle into one piece of wood and then using a special pocket hole screw to attach it to another piece of wood. This method is commonly used in woodworking for building cabinets, furniture, and other projects.

The pocket hole itself is a small hole that is drilled at an angle into the wood. The angle of the hole is typically around 15 degrees, which allows the screw to be driven in at an angle and still provide a strong joint. The pocket hole is typically drilled using a special jig that holds the wood in place and guides the drill bit at the correct angle.

Pocket hole joinery is a popular method for several reasons. First, it is relatively easy to learn and does not require a lot of expensive tools or equipment. Second, it is a fast method of joining wood together, as the pocket hole screws can be driven in quickly and easily. Finally, pocket hole joinery provides a strong joint that can withstand a lot of stress and strain.

When it comes to pocket hole joinery, the type of screw that is used is important. Kreg pocket hole screws are a popular choice, and they are recognizable by their distinctive blue color. The blue color is actually a type of coating that is applied to the screw to provide corrosion resistance and make it easier to drive into the wood.

Kreg pocket hole screws are available in a variety of sizes and styles, making it easy to find the right screw for any project. They are also designed to work with a variety of different types of wood, including hardwoods, softwoods, and even plywood.

Overall, pocket hole joinery is a versatile and reliable method of joining wood together. Whether you are a beginner or an experienced woodworker, it is a technique that is worth learning. And with the right tools and screws, it is easy to achieve strong, long-lasting joints that will stand the test of time.

The Role of Moisture

The blue color of Kreg screws is not just for aesthetics. It actually serves a functional purpose. One of the main factors that affect the performance of pocket-hole joinery is moisture. When wood is exposed to moisture, it can expand or contract, which can cause joints to loosen over time.

To combat this issue, Kreg uses a special coating on their screws called Blue-Kote™. This coating provides up to 400% more rust resistance than zinc-plated screws, making them ideal for use in damp or wet environments. The three anti-corrosion layers of Blue-Kote™ Screws help to prevent rust and corrosion, which can weaken the screws and the joints they hold together.

Moisture can also affect the strength of the wood itself. Wet or damp wood can be weaker than dry wood, which can affect the holding power of screws. Kreg screws are designed to work with all types of wood, including pressure-treated wood, which is often used in outdoor projects. The Blue-Kote™ coating helps to protect the screws from the chemicals used in pressure treatment, ensuring that they will last for many years.

In addition to protecting the screws from moisture, the Blue-Kote™ coating also makes them easy to drive into the wood. The self-tapping screw tips make it easy to create a strong joint quickly and easily. The case-hardened steel used in Kreg screws is also important, as it ensures that the screws won’t bend or break during installation.

Overall, the Blue-Kote™ coating on Kreg screws plays an important role in ensuring the strength and durability of pocket-hole joinery. By protecting the screws from moisture and rust, Kreg screws can create strong, long-lasting joints that will stand up to the test of time.

Understanding Hardwoods Vs Softwoods

When it comes to woodworking, it’s important to understand the differences between hardwoods and softwoods. While the names might suggest that hardwoods are harder and denser than softwoods, that’s not always the case. In fact, some softwoods can be harder and denser than some hardwoods.

Characteristics of Hardwoods

Hardwoods come from deciduous trees that lose their leaves in the fall. Some common hardwoods include oak, maple, and cherry. Hardwoods are generally denser and stronger than softwoods, making them ideal for furniture, flooring, and other high-stress applications. They also tend to have a more complex grain pattern and are more resistant to wear and tear.

Characteristics of Softwoods

Softwoods come from coniferous trees that keep their needles year-round. Some common softwoods include pine, spruce, and cedar. Softwoods are generally less dense and weaker than hardwoods, but they are easier to work with and more affordable. They are commonly used for building materials, such as framing and decking.

Pine as a Softwood

Pine is a common softwood that is often used in woodworking projects. It’s affordable, easy to work with, and readily available. Pine is also lightweight and has a straight grain pattern, making it ideal for projects that require a uniform look. However, pine is not as strong or durable as hardwoods and is more prone to dents and scratches.

Overall, the choice between hardwoods and softwoods depends on the specific project and its requirements. Understanding the characteristics of each type of wood can help woodworkers make informed decisions about which type of wood to use for their projects.

Associated Products

When it comes to Kreg screws, there are a few associated products that are worth mentioning. These products are designed to work in conjunction with Kreg screws to make woodworking projects easier and more efficient.

Kreg Pocket-Hole Jig

The Kreg Pocket-Hole Jig is a tool that makes it easy to create pocket holes for Kreg screws. This jig allows users to drill pocket holes at the perfect angle and depth every time, ensuring that Kreg screws will fit snugly and securely in the pocket holes. There are several different models of the Kreg Pocket-Hole Jig available, each designed for different types of projects and skill levels.

Kreg Pocket-Hole Screws

Kreg Pocket-Hole Screws are specially designed screws that are used with the Kreg Pocket-Hole Jig. These screws are available in a variety of lengths, finishes, and thread types, making it easy to find the right screw for any project. The blue-colored screws are known as Blue-Kote™ Pocket-Hole Screws, and they are designed to provide rust-resistant performance.

Kreg Pocket-Hole Plugs

Kreg Pocket-Hole Plugs are used to cover up pocket holes that are no longer needed. These plugs are available in a variety of wood types and finishes, allowing them to blend seamlessly into the surrounding wood. Kreg Pocket-Hole Plugs are easy to install and provide a professional-looking finish to any project.

Kreg Screw Selector Tool

The Kreg Screw Selector Tool is an online tool that helps users choose the right Kreg screw for their project. This tool takes into account the type of wood being used, the thickness of the wood, and the type of joint being created to recommend the perfect screw for the job. The Kreg Screw Selector Tool is a valuable resource for anyone who wants to ensure that their Kreg screws are being used correctly.

Overall, these associated products are designed to work in harmony with Kreg screws to make woodworking projects easier and more efficient. By using these products, users can ensure that their projects are built to the highest possible standards and will stand the test of time.

Screw Shapes

Kreg screws come in two shapes: conical and flat. The conical shape is the most common and is used for joining two pieces of wood together. The flat shape is used for attaching a piece of wood to a surface.

The conical shape is designed to allow the screw to be driven into the wood at an angle, which creates a strong joint. The angle of the screw also allows it to be hidden from view, which is ideal for furniture and other projects where aesthetics are important. The conical shape is also self-tapping, which means that it creates its own thread in the wood as it is driven in.

The flat shape is designed to sit flush with the surface of the wood, which makes it ideal for attaching a piece of wood to a surface. The flat shape also has a larger head than the conical shape, which provides more surface area for the screw to grip onto the wood. This makes it ideal for attaching a piece of wood to a surface that may be prone to movement, such as a tabletop or a shelf.

Overall, both conical and flat shapes are important for different types of woodworking projects. The choice of which shape to use will depend on the specific needs of the project.

The Self-Tapping Tip

One of the unique features of Kreg screws is their self-tapping tip. This tip allows the screw to create its own hole as it is driven into the wood, eliminating the need for pre-drilling. The self-tapping tip also helps to prevent splitting and cracking of the wood, making it a popular choice for woodworkers.

The self-tapping tip is especially useful when working with harder woods or when assembling thicker pieces of wood. The screw’s threads are designed to cut into the wood as it is driven in, creating a secure and tight joint. This feature also helps to reduce the amount of torque needed to drive the screw, making it easier and faster to use.

Kreg screws come in a variety of sizes and thread types, each designed for specific applications. The self-tapping tip is found on most Kreg screws, including the fine-thread type used for attaching drywall to steel studs.

Overall, the self-tapping tip is a key feature of Kreg screws, making them a popular choice among woodworkers and DIY enthusiasts. Its ability to create its own hole and prevent splitting and cracking of the wood makes it a reliable and efficient choice for any woodworking project.

Pressure-Treated Material

Kreg Blue-Kote pocket-hole screws are an excellent choice for use with pressure-treated materials. Pressure-treated lumber is wood that has been chemically treated to resist rot, decay, and insect damage. It is commonly used for outdoor projects such as decks, fences, and outdoor furniture.

One of the key benefits of using Kreg Blue-Kote screws with pressure-treated lumber is their corrosion resistance. The Blue-Kote coating provides a triple-layer protection against corrosion, making them ideal for use in outdoor environments. In fact, Blue-Kote screws provide rust-resistance up to 400% greater than zinc-plated screws.

Another benefit of using Kreg Blue-Kote screws with pressure-treated lumber is their strength. The coarse-thread design of Kreg pocket-hole screws provides maximum holding power and prevents the wood from splitting. This is especially important when working with pressure-treated lumber, which can be more prone to splitting than other types of wood.

It is important to note that not all Kreg screws are suitable for use with pressure-treated lumber. While Blue-Kote screws are specifically designed for use in outdoor environments, other types of Kreg screws may not be. It is always important to check the product specifications before using any type of screw with pressure-treated lumber.

Overall, Kreg Blue-Kote pocket-hole screws are an excellent choice for use with pressure-treated materials. Their corrosion resistance and strength make them ideal for outdoor projects, and their coarse-thread design helps prevent the wood from splitting.

The Long-Lasting Joint

Kreg screws are one of the most popular types of screws used in woodworking, and they are known for their blue color. But why are Kreg screws blue? The answer is simple: it’s a trademark color that Kreg Tool Company uses to differentiate its screws from other brands.

Kreg screws are specially designed to work with pocket-hole joinery, which is a popular method of joining two pieces of wood together. The pocket-hole joint is a long-lasting joint that is strong and durable. It is created by drilling a hole at an angle into one piece of wood and then joining it to another piece of wood with a screw.

The pocket-hole joint is a great option for those who want a strong, long-lasting joint without the need for complicated joinery techniques. The joint is also easy to assemble and can be done quickly with the right tools.

Kreg screws are an essential part of creating a pocket-hole joint that is strong and long-lasting. The screws are designed to be self-tapping, which means they can cut their own threads into the wood as they are driven in. This makes it easier to create a tight, secure joint that will last for years to come.

In addition to being self-tapping, Kreg screws are also available in a variety of lengths and sizes to accommodate different types of wood and thicknesses. This makes it easy to find the right screw for your project and ensures that you get a strong, long-lasting joint every time.

Overall, the pocket-hole joint created with Kreg screws is a strong, durable, and long-lasting joint that is perfect for woodworking projects of all kinds. With the right tools and techniques, anyone can create a pocket-hole joint that will stand the test of time.

The Art of Woodworking

Woodworking is an art that has been practiced for centuries. It involves shaping and joining pieces of wood to create functional or decorative objects. The process requires skill, patience, and attention to detail. The use of the right tools and materials is also essential to produce high-quality results.

One of the most important aspects of woodworking is the joining of wood pieces. There are different methods of joining wood, including doweling, biscuit joining, and mortise and tenon joints. However, one of the most popular methods used today is pocket-hole joinery.

Pocket-hole joinery involves drilling a hole at an angle into one piece of wood and then joining it to another piece using a pocket-hole screw. The pocket-hole screw is specially designed to have a self-tapping thread that creates a strong joint between the two pieces of wood.

Kreg Tool Company is one of the leading manufacturers of pocket-hole joinery tools and accessories. The company’s flagship product is the Kreg Jig, a tool that makes it easy to create pocket holes with precision and accuracy. Kreg also produces a range of pocket-hole screws in different sizes and finishes, including the popular Blue-Kote™ screws.

The Blue-Kote™ screws are coated with a blue-colored finish that provides rust and corrosion resistance. The coating also makes the screws easier to drive into the wood, reducing the risk of splitting the wood. The Blue-Kote™ screws are available in different lengths and thread types, making them suitable for a variety of woodworking projects.

In conclusion, woodworking is a time-honored craft that requires skill, patience, and attention to detail. Pocket-hole joinery is a popular method of joining wood, and Kreg Tool Company is one of the leading manufacturers of pocket-hole joinery tools and accessories. The Blue-Kote™ screws are a popular choice among woodworkers due to their rust and corrosion resistance and ease of use.

Frequently Asked Questions

What makes Kreg Blue-Kote Screws suitable for pressure-treated lumber?

Kreg Blue-Kote Screws are suitable for pressure-treated lumber because they are coated with three anti-corrosion layers. This coating provides excellent protection against rust and corrosion, making them ideal for use in damp or wet environments. Additionally, the Blue-Kote coating provides a high level of resistance to the chemicals used in pressure-treated lumber, ensuring that the screws will not corrode or degrade over time.

Why are pocket-hole screws different from regular screws?

Pocket-hole screws are different from regular screws because they are designed specifically for use with pocket-hole joinery. Pocket-hole screws have a self-tapping tip that allows them to be easily driven into the pocket hole without the need for pre-drilling. Additionally, pocket-hole screws have a flat-bottomed head that seats flush with the surface of the workpiece, providing a strong and secure joint.

What size Kreg screw should I use for 2×4?

The size of Kreg screw you should use for a 2×4 depends on the thickness of the 2×4 and the type of joint you are creating. For a standard butt joint, a 2-1/2 inch screw is recommended for a 2×4 that is 1-1/2 inches thick. For a joint that requires additional strength, such as a miter joint, a longer screw may be necessary. It is important to consult the Kreg Screw Selector tool or the Kreg Jig manual to determine the appropriate screw size for your specific project.